Composite bulletproof unit material and production method thereof

A unit layer, bulletproof fiber technology, applied in the field of materials, can solve the problem of no relevant reports on the correlation of bulletproof fiber resin adhesives, and achieve the effect of excellent performance and excellent ballistic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

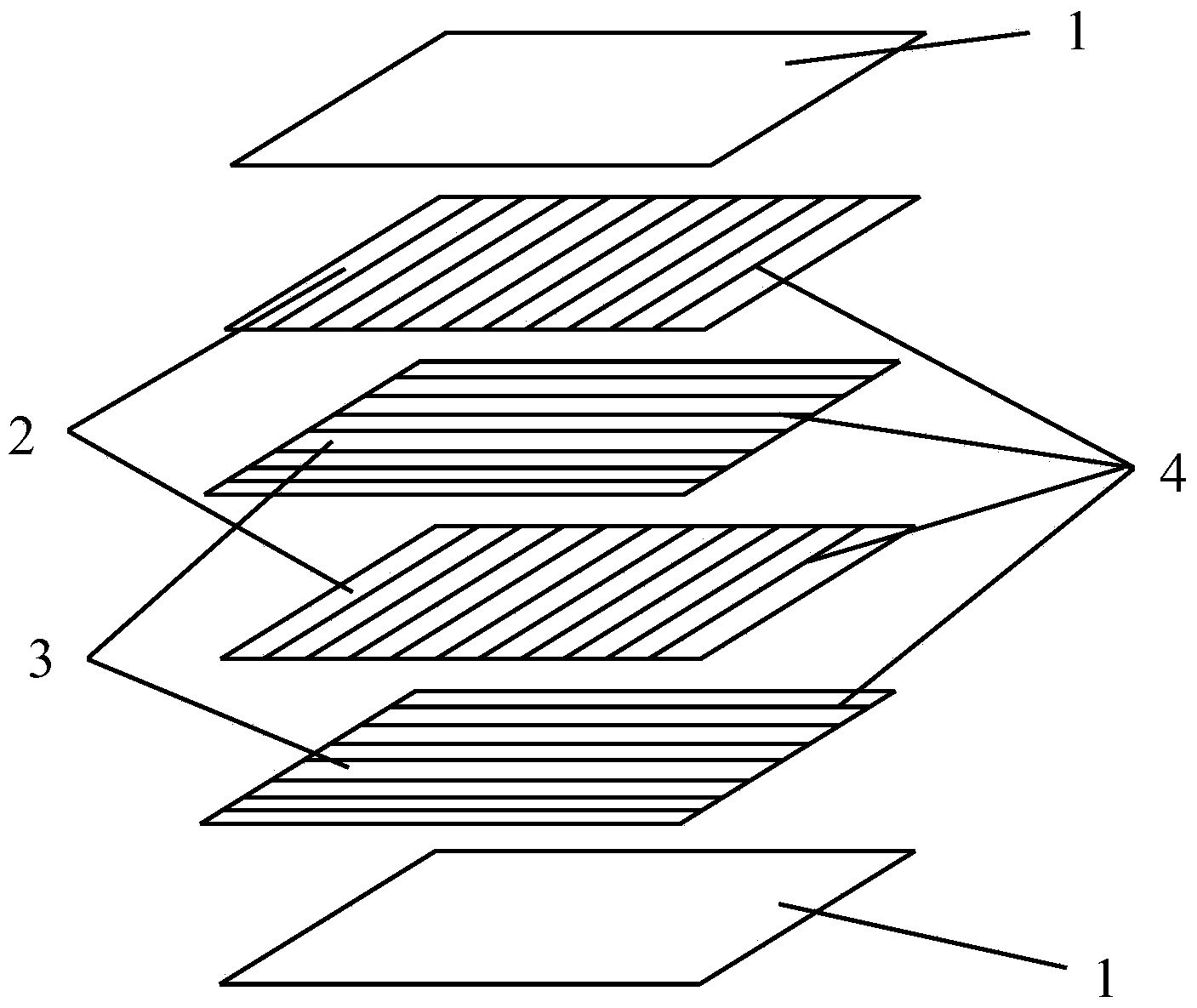

Embodiment 1

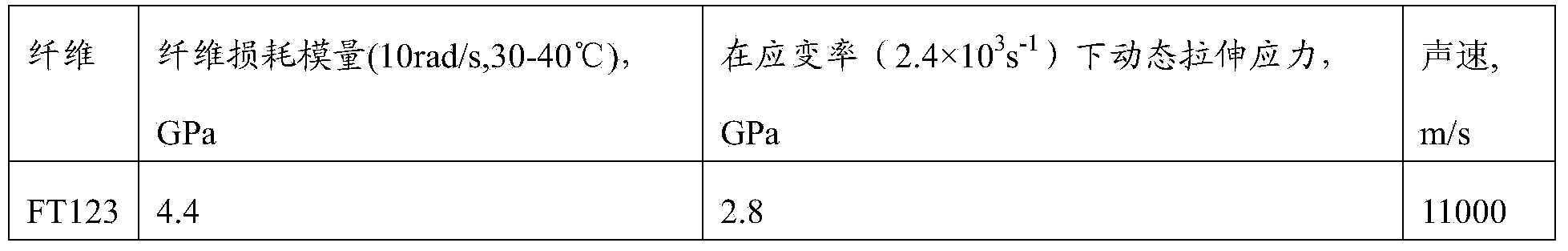

[0063] FT123 fiber, 800d / 528f (strength 32cN / dtex, tensile modulus 1250cN / dtex, strain sensitivity rate at 2.4×10 3 the s -1 When the dynamic tensile stress ≥ 2.8GPa. The high-strength high-modulus polyethylene fiber with a sound wave transmission speed of 11000m / s) is unwound from the creel, and under the traction of the tractor, the fibers are spread and arranged in parallel and evenly at equal intervals within a certain width through the steel needles arranged in parallel. , the fiber is quantitatively impregnated through a glue tank containing an acrylate resin adhesive and a squeegee device, wherein the tensile modulus of the acrylate resin is 5MPa, and the viscosity and loss modulus are increased by adding rosin tackifier emulsion to make it Under the same test conditions, the loss modulus is consistent with that of the bulletproof fiber at 30-40°C. The impregnated unidirectional fiber tape is heated and dried by hot air in the air cylinder, and finally wound up to for...

Embodiment 2

[0068] Repeat Example 1, except that the two-layer orthogonal composite bulletproof unit material in Example 1 is again subjected to orthogonal thermal compounding to prepare a four-layer orthogonal composite bulletproof unit material structure.

[0069] Sample preparation of the bulletproof chip, cutting the composite bulletproof unit material into a square sheet of 40×40cm, and then stacking it to an area density of 4.0kg / m 2 target sheet. Detect the dent and V50 value of anti-9mm full metal jacket bullet. Table 2 shows that the bulletproof chip composed of this composite bulletproof unit material meets the requirements and is better than Comparative Example 3.

[0070] Table 1 and Table 2 show the comparative examples of specific embodiments and the relevant parameters of the examples.

[0071] Table 1

[0072]

[0073] Table 2

[0074] example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com