A continuous tensile test device and method for cylindrical multi-sample in liquid helium temperature zone

A tensile test and multi-sample technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as low efficiency, and achieve the effects of improving efficiency, improving test efficiency, and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

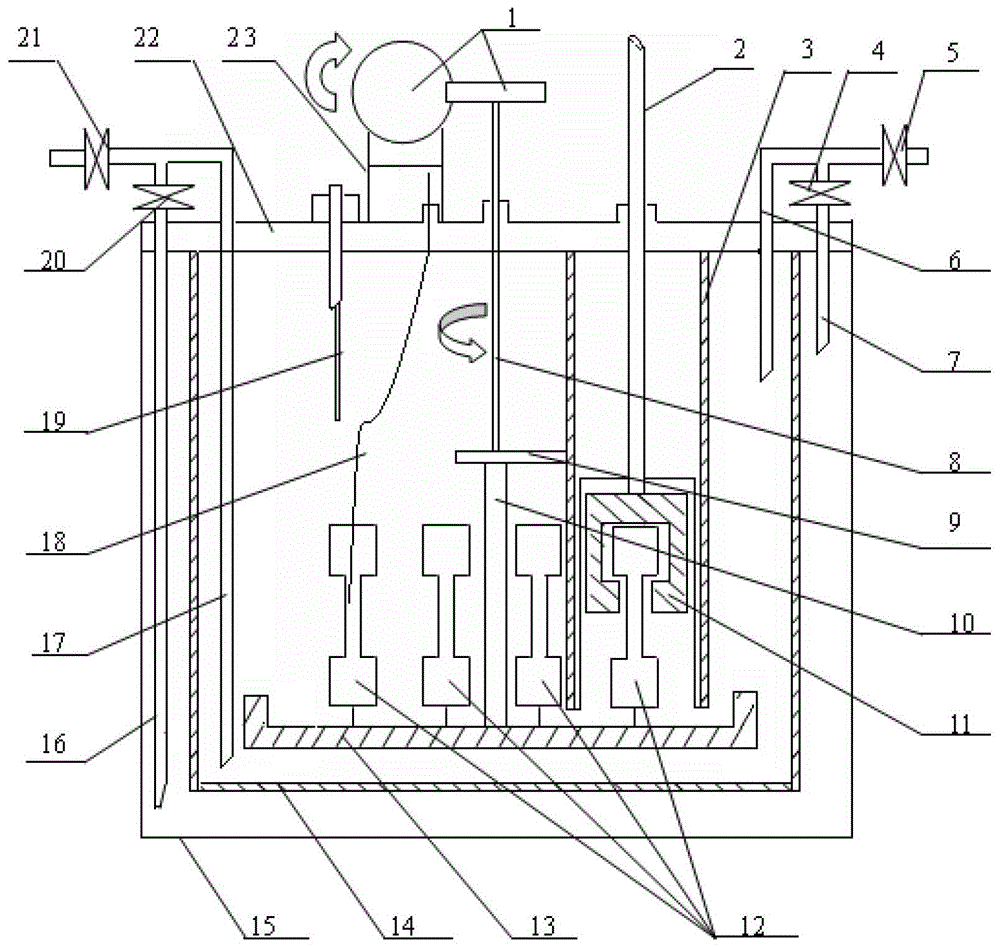

[0038] as attached figure 1As shown, a cylindrical multi-sample low-temperature continuous tensile testing system includes a hollow cylindrical outer Dewar 15, and an inner Dewar 14 that is also a hollow cylindrical outer Dewar is arranged inside the outer Dewar 15, and is arranged on the top of the outer Dewar 15. Dewar sealing cover 22; eight through holes are set on the Dewar sealing cover 22, two of which communicate with the space between the inner Dewar 14 and the outer Dewar 15, two communicate with the space in the inner Dewar 14, and one Set in the center of the Dewar seal cover 22, the rotating rod 8 of the rotating mechanism passes through the hole, an eccentric large hole set in the Dewar seal cover 22 is used for the actuating rod 2 to pass through, and the remaining two holes are respectively used for test signal The detection line 18 and the liquid helium level gauge 19 are introduced; the low temperature tensile test system is provided with an outer gallbladder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com