Transmission optical component damage threshold improvement method based on multi-iteration etching

An optical element, iterative etching technology, applied in the coating and other directions, to achieve the effect of increasing the damage threshold, increasing the damage threshold, and being highly targeted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

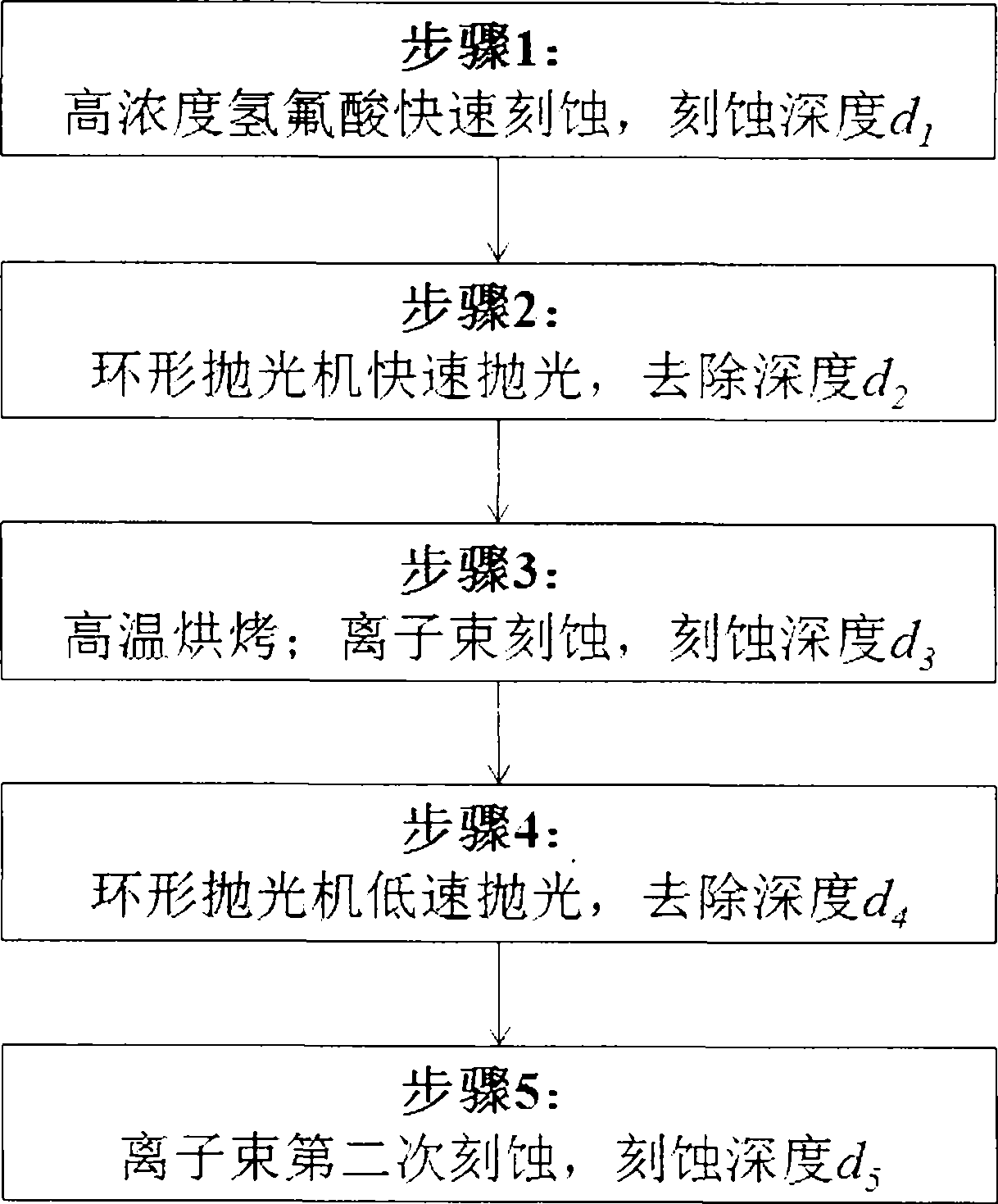

[0049] Such as figure 1 As shown, a method for increasing the damage threshold of a transmission optical element based on multiple iterative etching, the method includes the following steps:

[0050] ①Firstly, the optical element is etched with hydrofluoric acid solution in an ultrasonic environment, and the etching depth is d 1 , and then rinse and spray with deionized water;

[0051] 11) The ultrasonic environment is 40kHz, 80kHz, 120kHz, 140kHz, 170kHz, 220kHz and 270kHz seven-frequency cycle vibration;

[0052] 12) The concentration of the hydrofluoric acid solution is 40%, the solution temperature is 60 degrees, the etching time is 5-30 minutes, and the etching depth is d 1 50-300 microns;

[0053] 13) The rinsing solution is deionized water, and the rinsing time is 30 minutes;

[0054] 14) The spraying solution is deionized water, and the spraying time is 10 minutes.

[0055] ②Use a ring polishing machine to polish the optical components, and the polishing removal d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com