Capacitive touch screen manufacturing method

A technology of capacitive touch screen and manufacturing method, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of many process steps, high production cost, production yield limit, etc., and meet the process operation requirements Convenience, product cost reduction, good promotion and popularization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

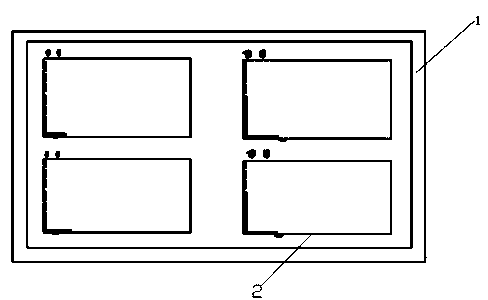

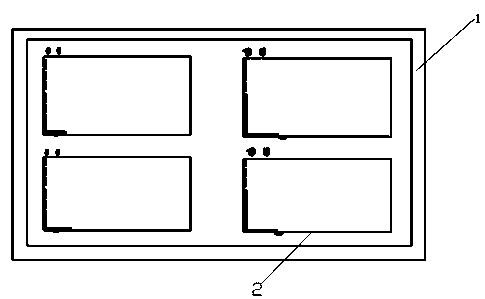

Image

Examples

Embodiment 1

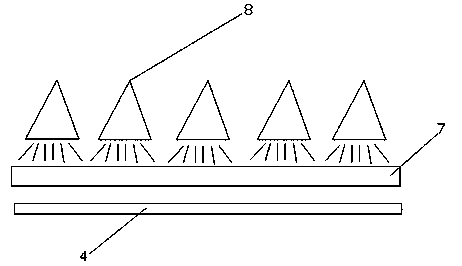

[0023] The silver paste on GLASS or FILM is burned and removed by laser light, so as to realize the molding of the circuit. The process flow is as follows: Figure 5 with Image 6 shown.

[0024] First, the conductive ink is coated on the screen, and a large piece of ink is printed on the ITO GLASS or ITO FILM from left to right by a scraper, and then baked and dried, and then the silver paste is burnt with laser light to produce the required circuit. The drying process here may also adopt natural drying, hot air drying and the like.

[0025] Compared with prior art, the beneficial effect of the present invention is:

[0026] 1. Laser forming lines have obvious advantages over screen printing in terms of line width requirements.

[0027] 2. Laser etching has obvious advantages over molybdenum aluminum molybdenum or screen printing in terms of environment, equipment and site requirements.

[0028] 3. Laser etching is significantly higher than screen printing in terms of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com