A kind of preparation method of oled device

A technology for a device and an etching barrier layer, which is applied in the field of preparation of OLED devices, can solve the problems affecting the display effect of the OLED device, the calculation of the thickness of the microcavity is complicated, the damage of the first insulating layer, etc., to achieve good optical effects and improve the etching efficiency The effect of high rate and etching ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

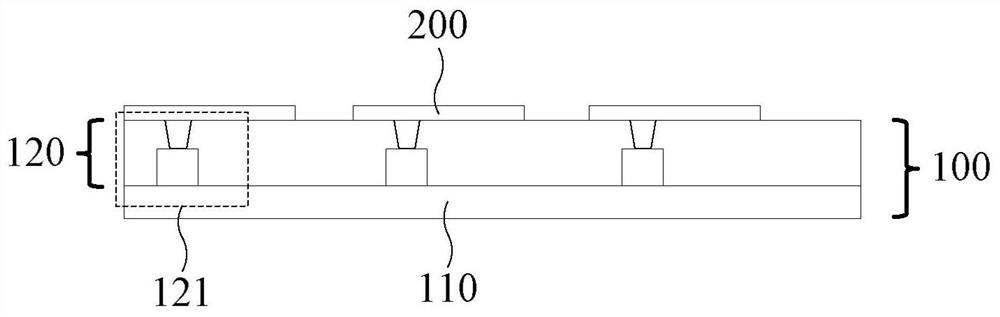

preparation example Construction

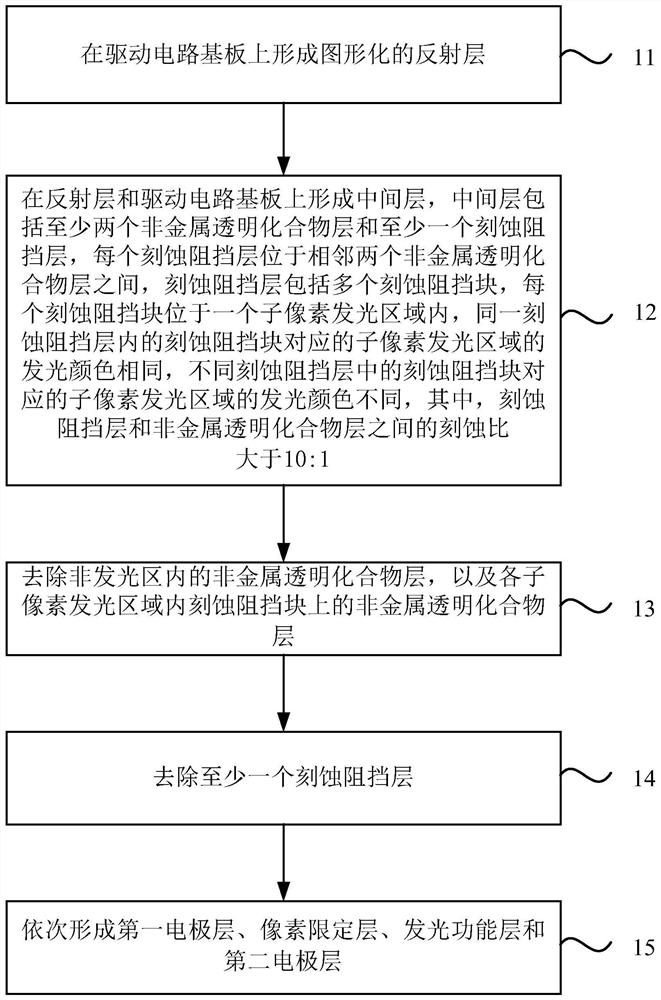

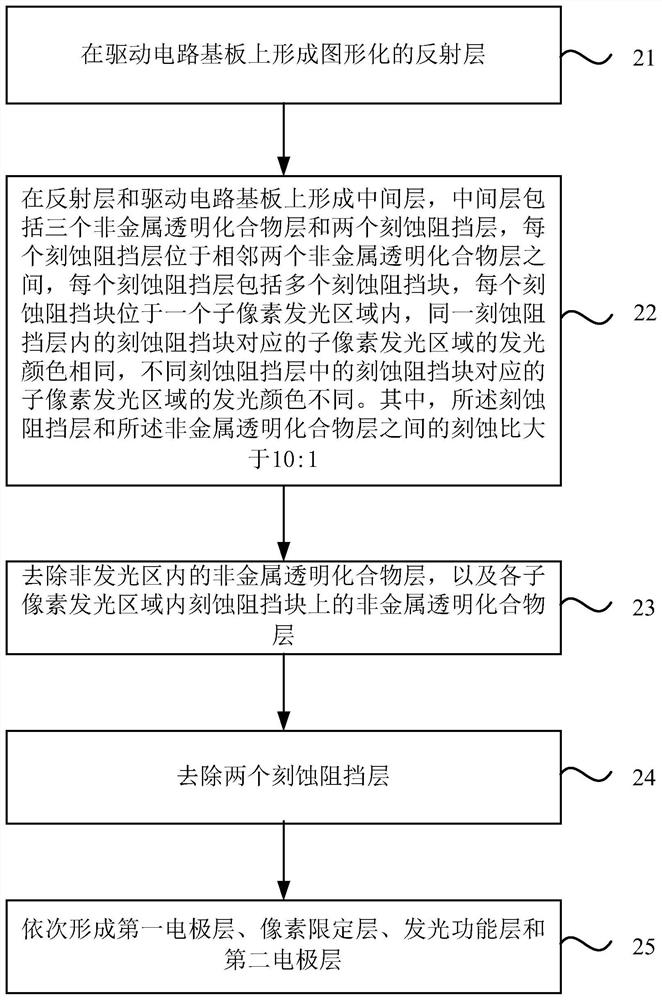

[0028] An embodiment of the present invention provides a method for preparing an OLED device, including:

[0029] forming a patterned reflective layer on the driving circuit substrate;

[0030] An intermediate layer is formed on the reflective layer and the driving circuit substrate, the intermediate layer includes at least two non-metallic transparent compound layers and at least one etching barrier layer, each of the etching barrier layers is located in two adjacent ones between the non-metallic transparent compound layers; the etching stopper layer includes a plurality of etching stopper blocks, each of the etching stopper blocks is located in a sub-pixel light-emitting area, and all the etching stopper blocks in the same etching stopper layer are The light-emitting colors of the sub-pixel light-emitting regions corresponding to the etching blocking blocks are the same, and the light-emitting colors of the sub-pixel light-emitting regions corresponding to the etching blocki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com