A fine metal mask manufacturing method suitable for high ppi

A technology of fine metal mask and manufacturing method, which is applied in the field of high PPI fine metal mask manufacturing, can solve the problems of high production input cost, low success rate, and difficult manufacturing, and achieve the effect of avoiding low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for manufacturing a fine metal mask suitable for high PPI, comprising the following manufacturing steps:

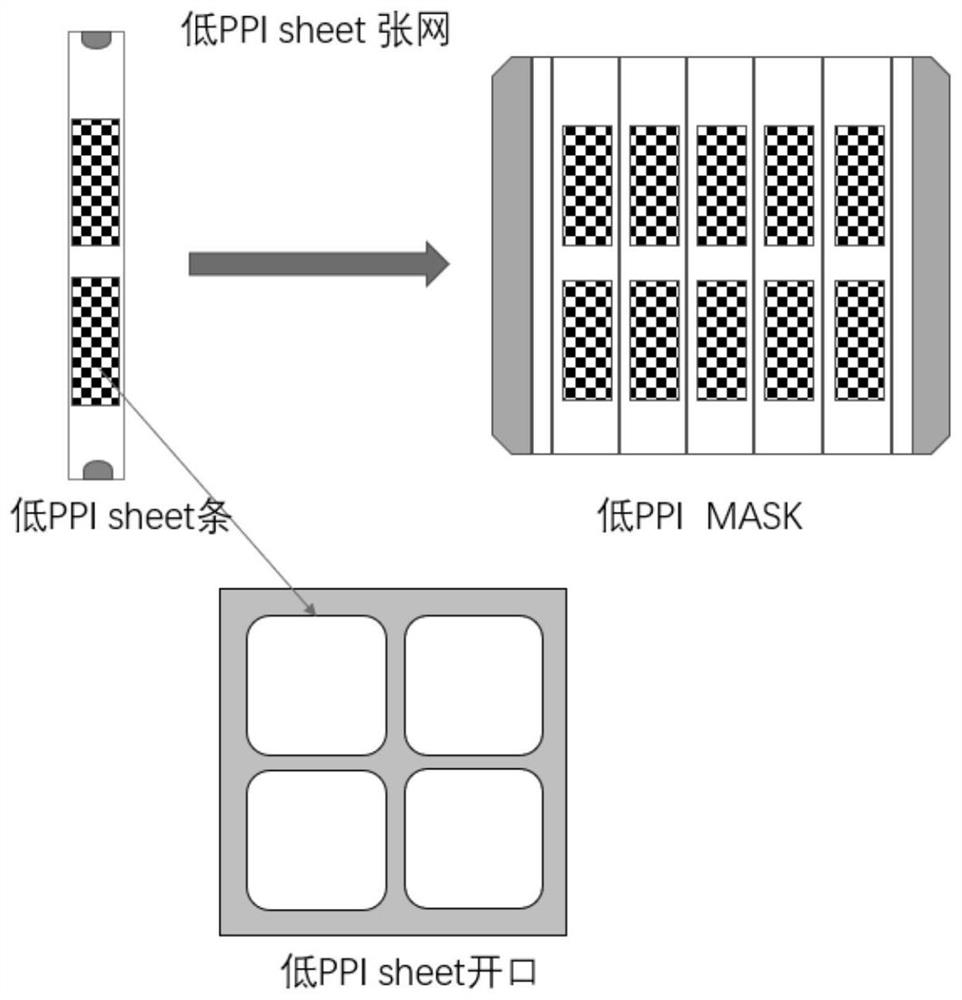

[0025] (1) According to the arrangement of high PPI pixels, prepare the corresponding low PPI fine metal mask: a. Including the mask metal frame, the netting machine, and several low PPI masks; b. The low PPI mask is the reason Tile alloy, the thickness is 20-30μm, and the PPI is 100-200; c. The low-PPI masks are respectively stretched, and the mask is grasped, aligned, stretched and welded on the metal by using a net-stretching machine. On the frame, after all mask welding is completed, it is a low PPI mask product;

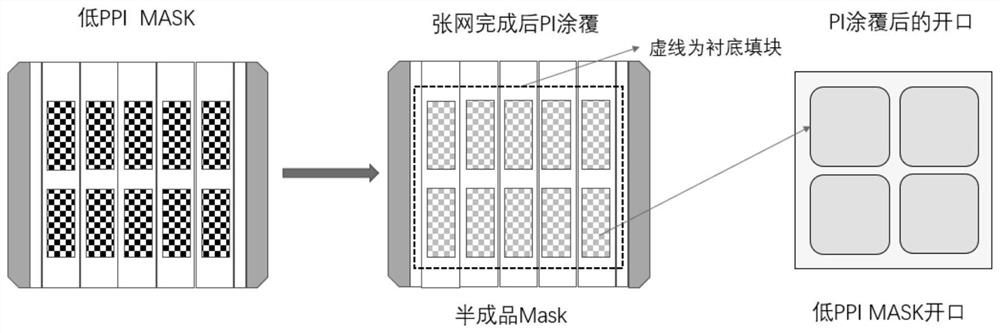

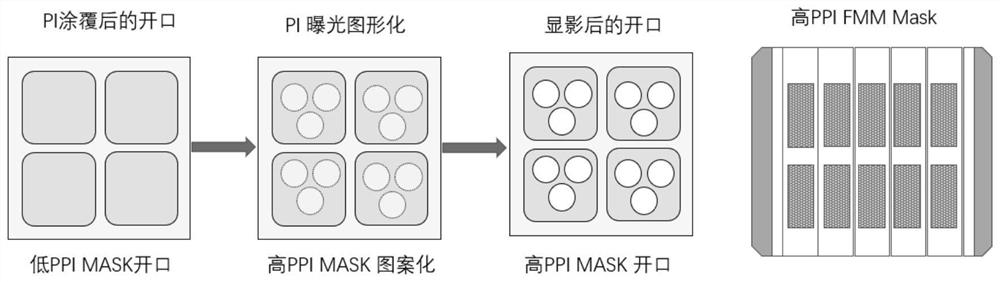

[0026] (2) Use a net stretching machine to stretch the low PPI mask and weld it to the frame to make a semi-finished fine metal mask. After the net is completed, the mask is coated with PI to form a film layer: a. Including PI coating Covering equipment and substrate filling block; b. The substrate filling block is polyethylene material wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com