600kw gas discharge electronic gun and application method thereof

A technology of gas discharge and electron gun, which is applied in the direction of discharge tubes, circuits, electrical components, etc., can solve the problems of complex structure, high skill and experience requirements, and high manufacturing and use costs of hot cathode electron guns, so as to improve the use value and scope of use, The effect of wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

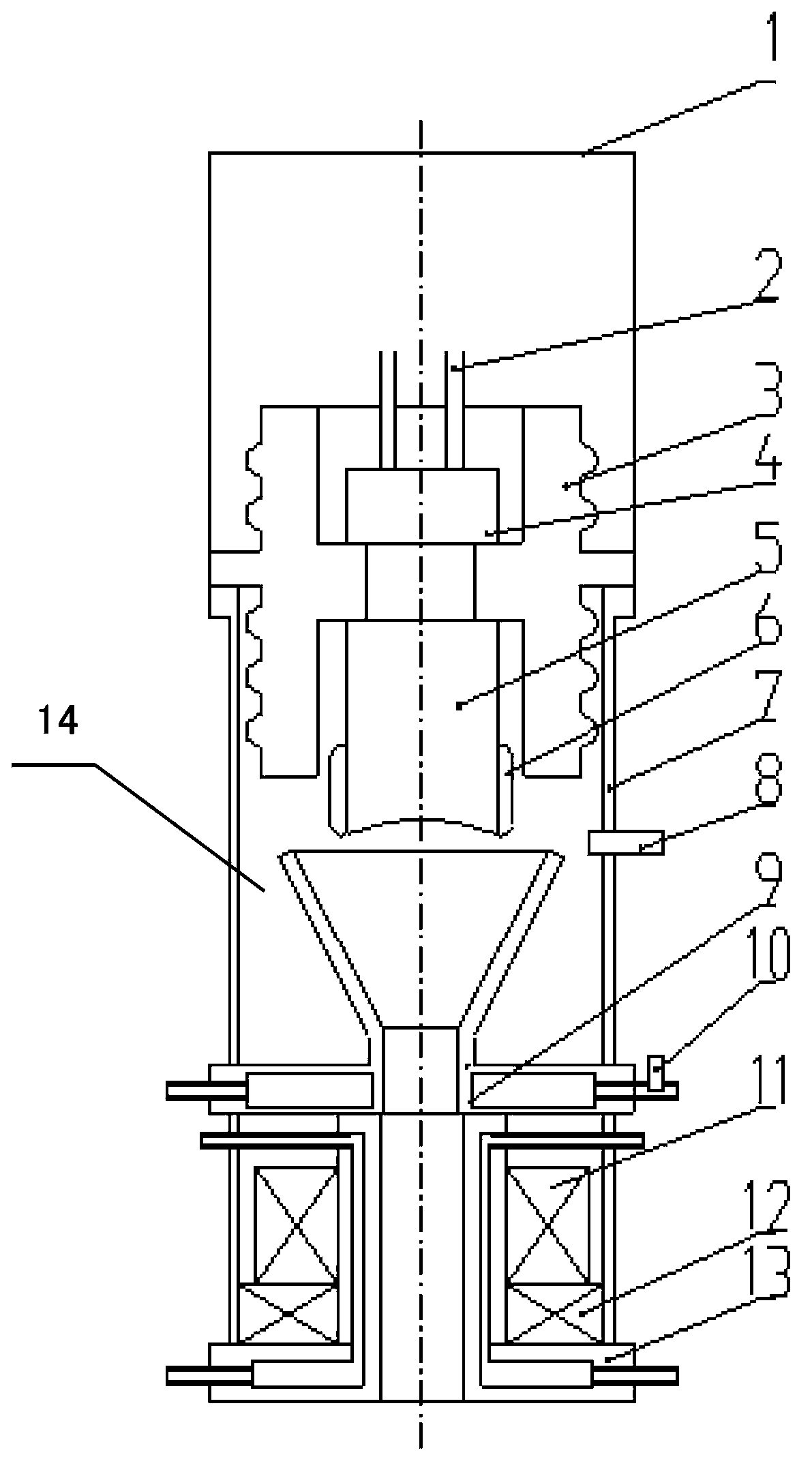

[0030] Such as figure 1 As shown, the present invention is a 600kw gas discharge electron gun led by the principle of glow discharge, which includes: the uppermost end is a gun cover 1, and the inner disk of the gun cover 1 has multiple circles of water pipes 2 (closed cooling water unit device as a cathode block) , to increase the resistance of the water pipe, a large cylinder 7 is installed under the gun cover, and an open-loop control inflation system 8 is installed on the large cylinder, which is mainly used to adjust the power of the electron gun and adjust the temperature of the gun chamber. There is a high-voltage insulating porcelain bottle 3 on the large cylinder, and the cold cathode cylinder 5, which is a key part for glow discharge, is installed in the large cylinder. The cold cathode cylinder 5 is equipped with a sealing fixture 4 for sealing cooling water and fixing the cold cathode. Two water pipes, one in and one out, are installed on the part 4, and the two wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com