Cantilever mechanism for piezoelectric power generation

A technology of piezoelectric power generation and cantilever beams, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Issues such as the overall bandwidth of the electric cantilever mechanism achieve the effect of enhancing the energy conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

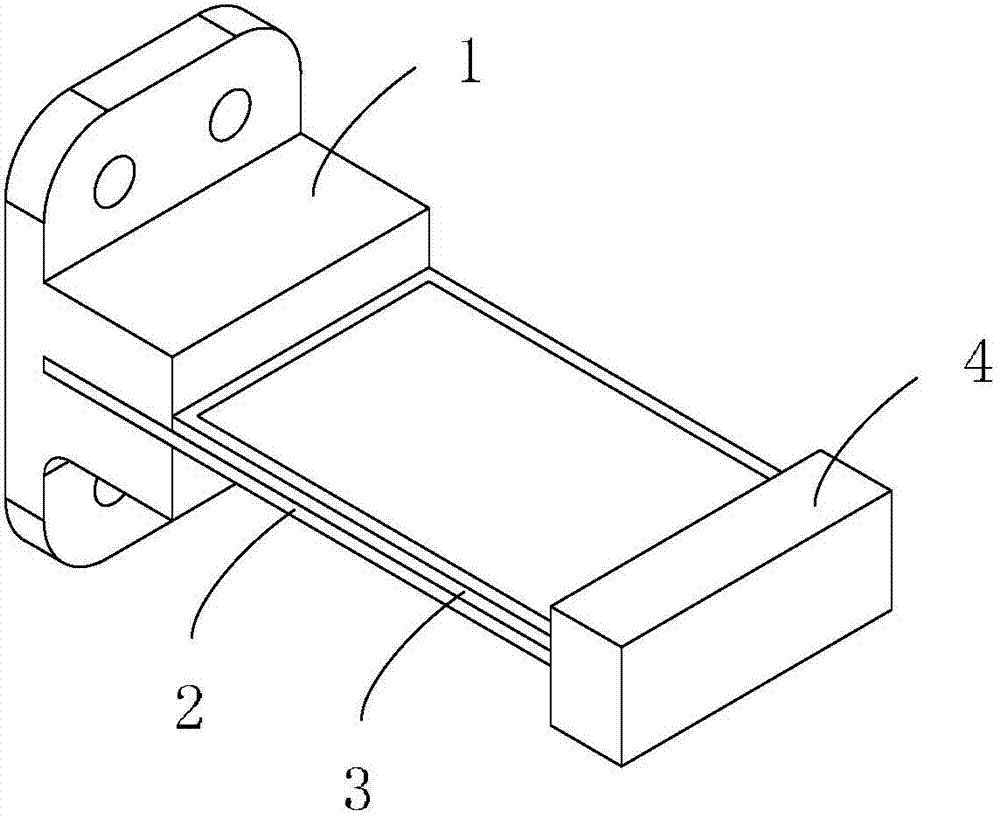

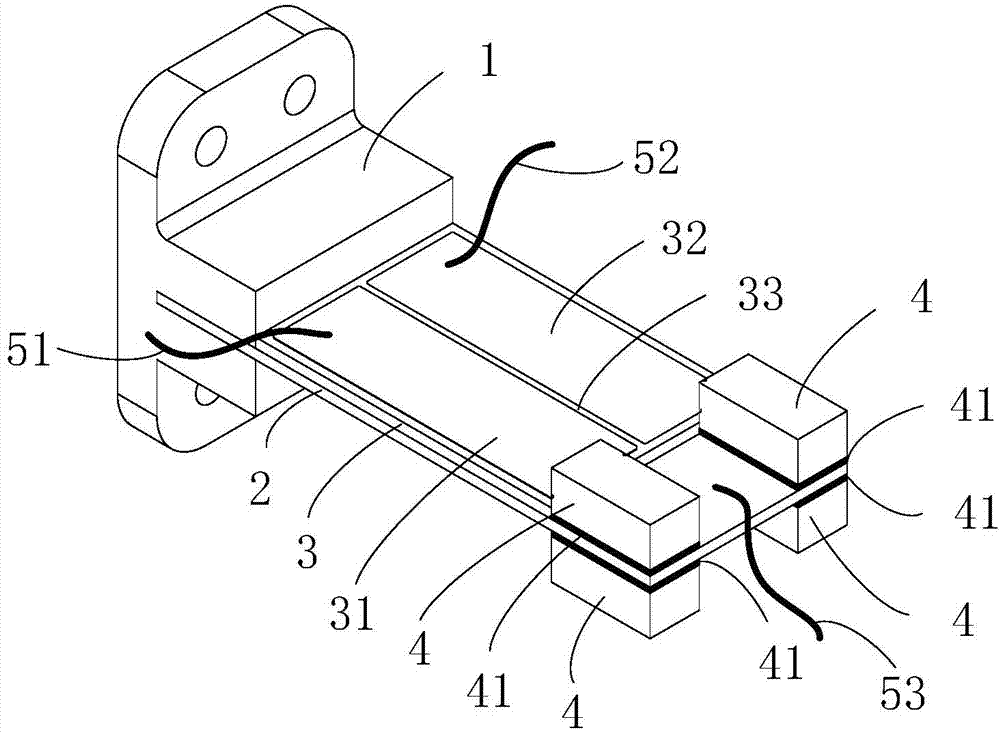

[0014] The structure and principle of the present invention will be further described in detail in the implementation examples given below in conjunction with the accompanying drawings.

[0015] refer to figure 2 , the double-inertia multi-mode piezoelectric cantilever generator mechanism of the present invention uses a base 1 that directly acts on the vibration source as the power input end of the system, and one end of the elastic substrate 2 made of metal material is bonded on the base 1, The other end is distributed with two groups of mass blocks 4 connected to the elastic substrate 2 through the adhesive layer 41, and the piezoelectric material sheet 3 is bonded to the surface of the elastic substrate. The piezoelectric material sheet 3 includes symmetrically arranged electrodes 31 and 32. The separation line 33 between each electrode 31 and the electrode 32 is along the midline of the cantilever beam from the base 1 to the direction of the distributed mass 4, the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com