Capacitive silicon miniature microphone and manufacturing method thereof

A microphone and capacitive technology, which is applied in the field of capacitive silicon micro-microphones, can solve the problems of difficult application of silicon micro-microphones, inability to work, and unreliable reliability, etc., and achieve superior charge storage performance, superior charge retention performance, superior high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the above-mentioned and other purposes, features and advantages of the present invention will be clearer. The drawings have not been drawn to scale, emphasis instead being placed upon illustrating the gist of the invention.

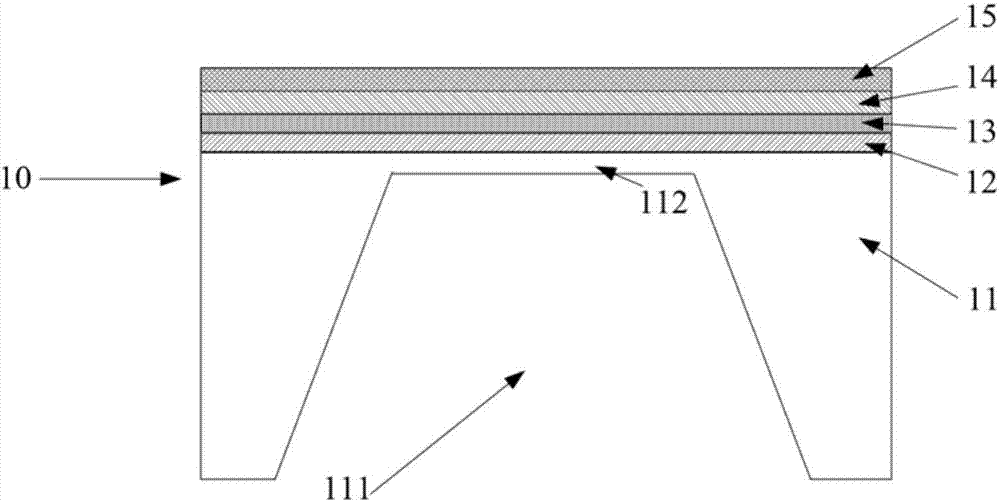

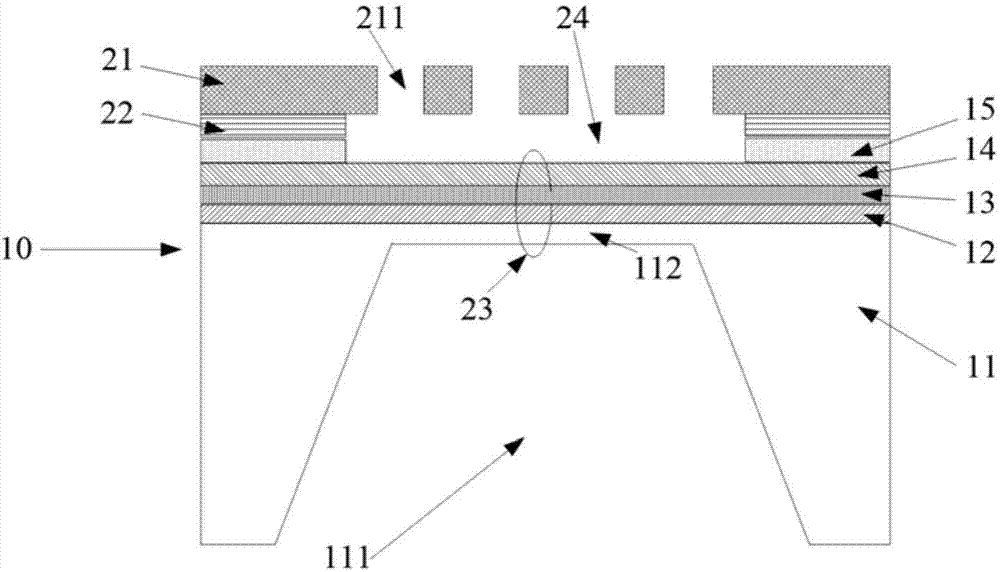

[0021] figure 1 It is a structural schematic diagram of the charge trap type non-volatile memory 10 which is a component of the capacitive silicon micro-microphone of the present invention. Such as figure 1 As shown, the charge trap type non-volatile memory 10 includes a substrate 11, and a cavity 111 is opened in the middle and lower position of the substrate 11. A tunneling layer 12 is provided on the lower board 112 , a dielectric layer is provided on the tunneling layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com