PTC thermistor and method for manufacturing PTC thermistor

A technology of thermistor and manufacturing method, applied in the direction of resistance manufacturing, resistors, non-adjustable metal resistors, etc., can solve the problems of indeterminate characteristics, inability to obtain PTC thermistors, etc., and achieve the effect of excellent resistance temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

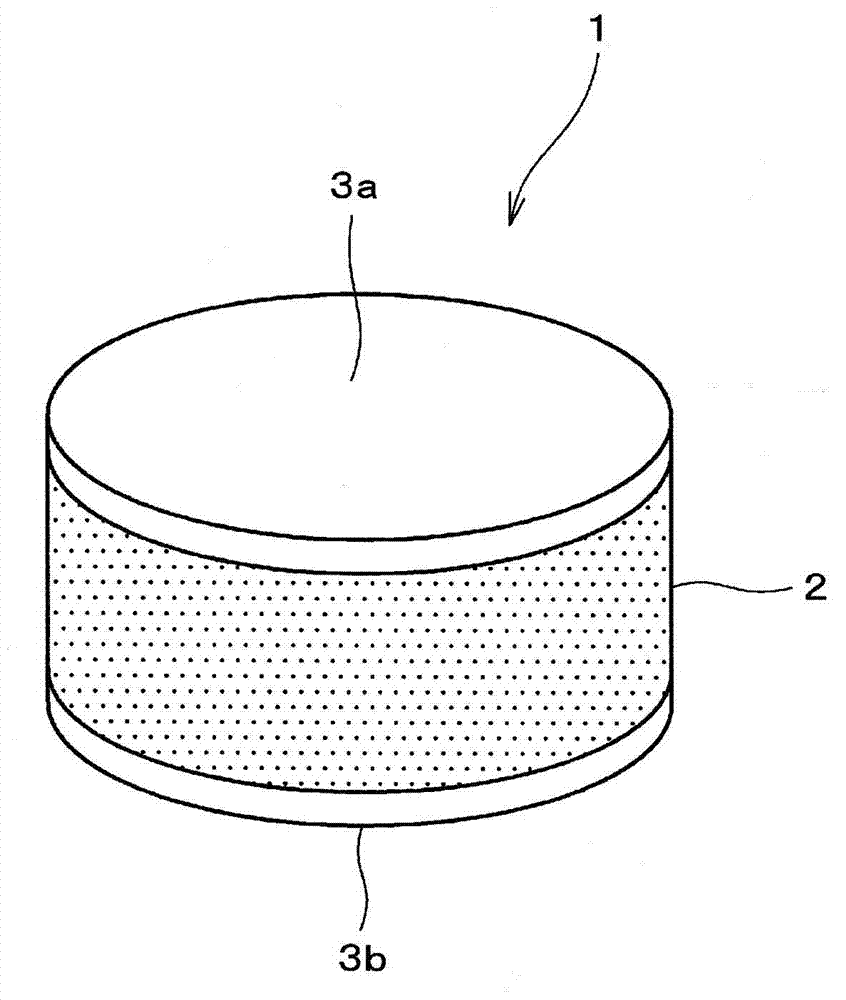

[0040] figure 1 It is a perspective view showing the PTC thermistor (positive characteristic thermistor) of the present invention.

[0041] This PTC thermistor 1 is provided with a pair of electrodes 3a, 3b on the front and back surfaces of a semiconductor ceramic base (thermistor base having positive resistance-temperature characteristics) 2 .

[0042] The PTC thermistor, for example, can be manufactured through the following steps:

[0043] (a) making an uncalcined semiconductor ceramic matrix;

[0044] (b) calcining the uncalcined semiconductor ceramic substrate to obtain such as figure 1 A semiconductor ceramic substrate 2 as shown;

[0045] (c) A pair of electrodes 3a, 3b are formed on the front and back surfaces of the semiconductor ceramic base 2 .

[0046] The ceramic material constituting the semiconductor ceramic matrix is a barium titanate-based semiconductor ceramic containing a perovskite-type compound including Ba, Ti, Sr, and Ca, Mn, and a semiconducting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com