Polyethylene additive compositions and articles made from same

A technology of polymers and compositions, applied in transportation and packaging, mechanical equipment, pipes, etc., can solve problems such as reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0013] It should be understood at the outset that, although an exemplary implementation of one or more embodiments is provided below, the disclosed systems and / or methods can be implemented using any number of techniques, now known or in existence. The disclosure should not be limited in any way to the exemplary implementations, drawings, and techniques illustrated below, including the exemplary designs and implementations illustrated and described herein, but rather within the scope of the appended claims and their equivalents Changes are made across the entire range.

[0014] To the extent that any definition or usage provided by any document incorporated herein by reference conflicts with the definition or usage provided herein, the definition or usage provided herein controls.

[0015] The terms "polymer", "polymer resin", "polyolefin", "polyolefin resin" and the like are used herein to cover any homopolymer of an olefin monomer or an olefin monomer with one or more comono...

Embodiment 1

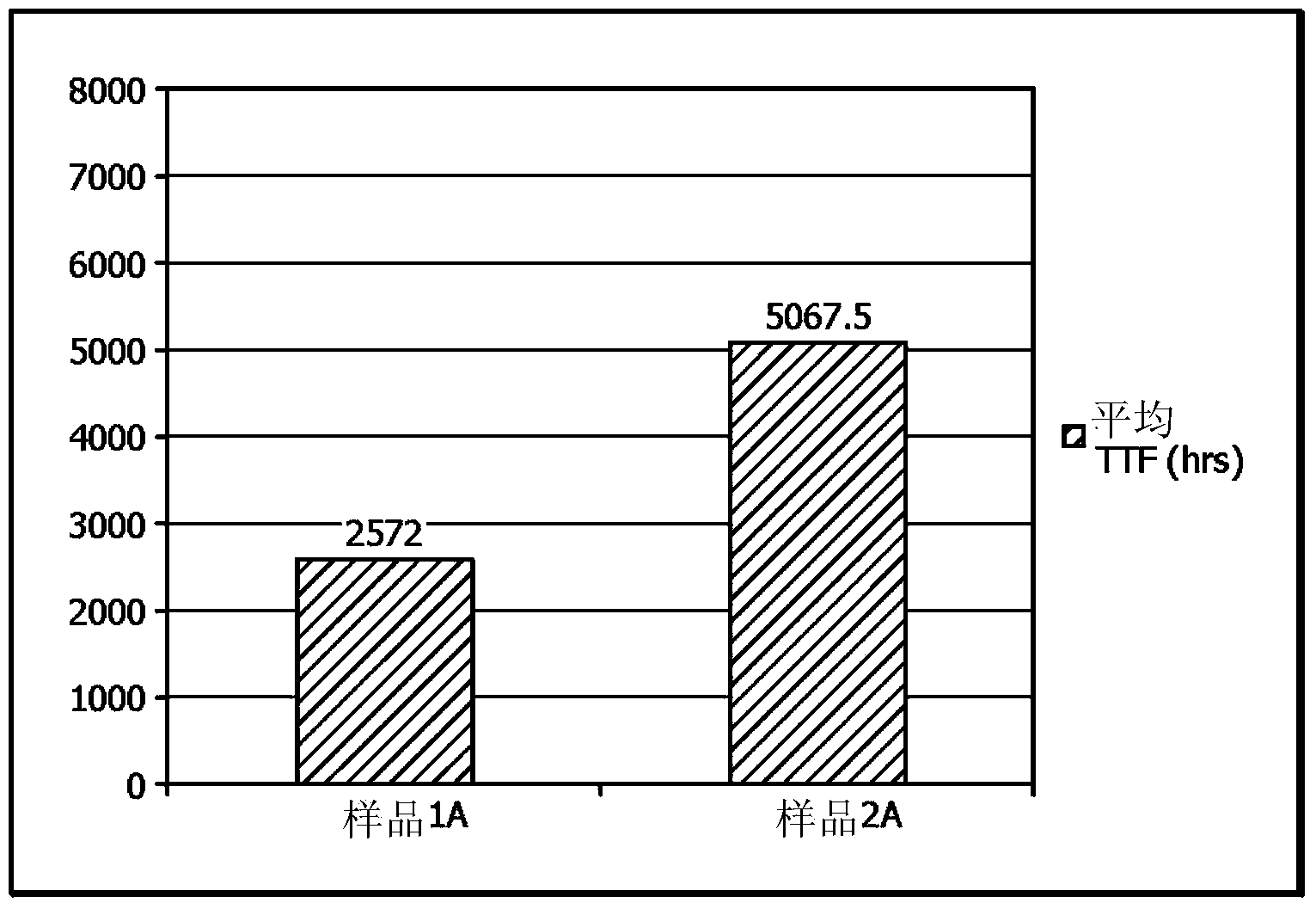

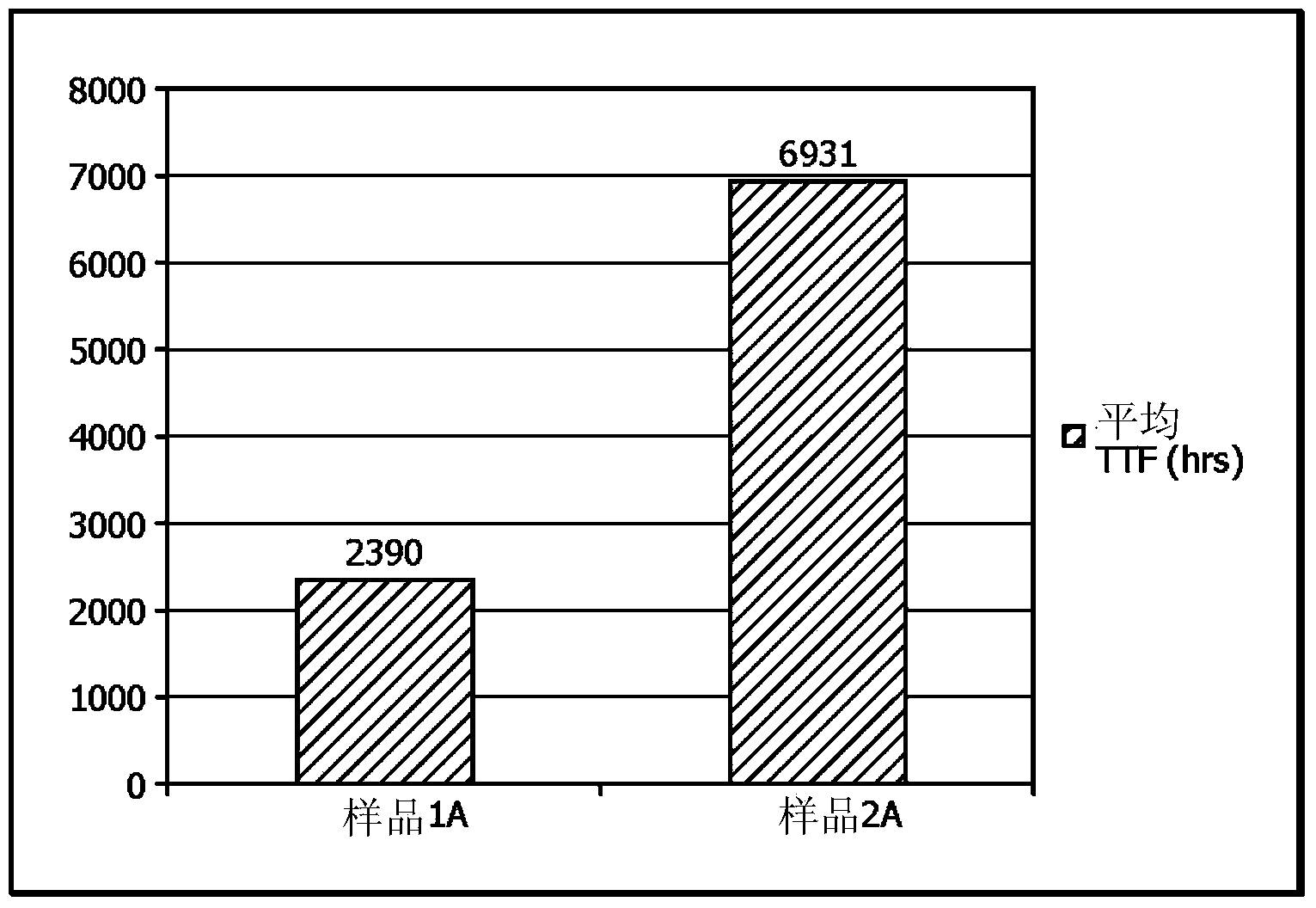

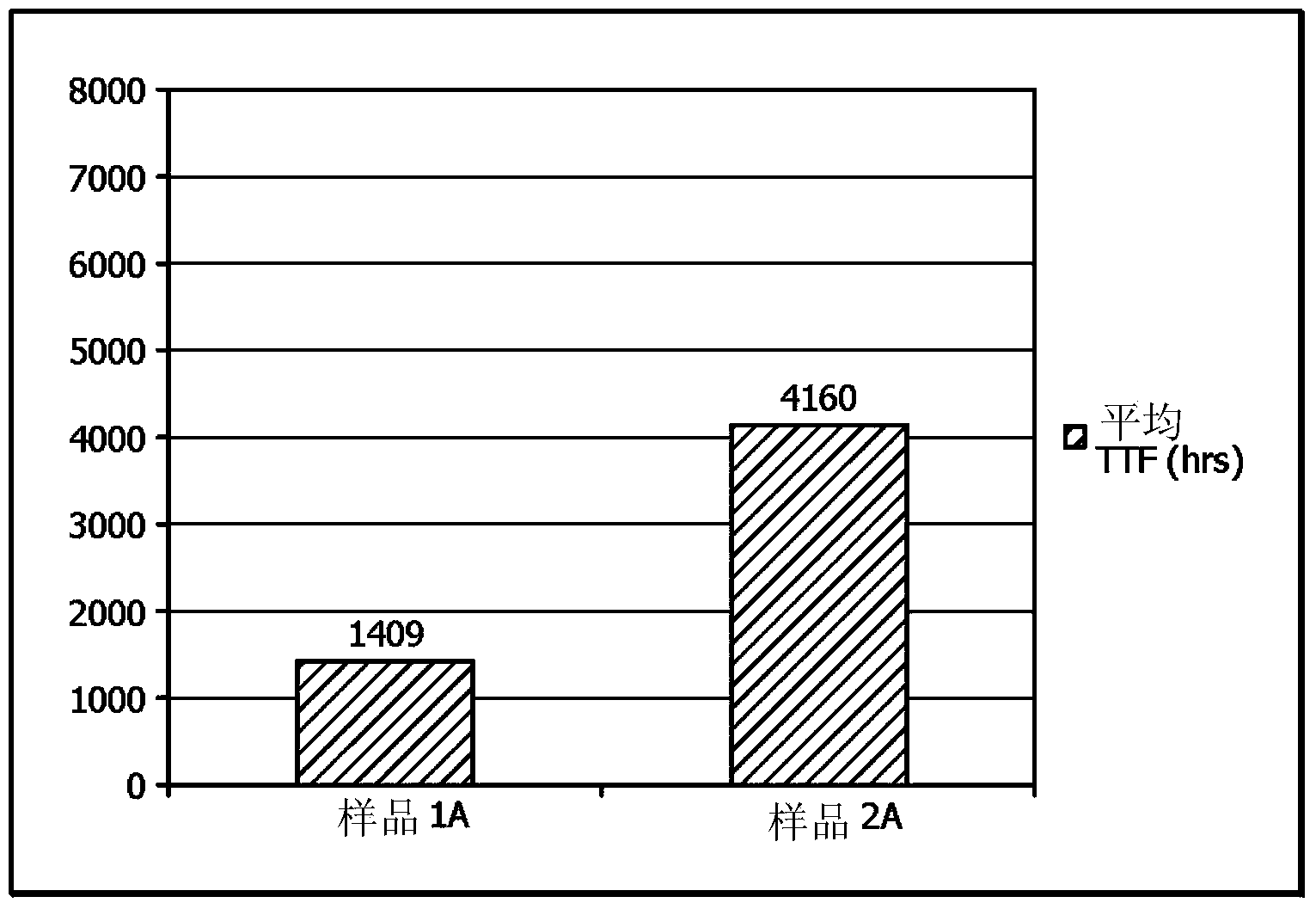

[0081] The effect of AID on the stability of tubes prepared from CWS-PC of the type described herein was investigated. Two sample compositions were prepared and tested for their ability to resist degradation when exposed to a chlorine source. All samples contain HP132 is used as the matrix resin. HP132 high density polyethylene is commercially available from Chevron Phillips Chemical Company LP. Sample 1 except Besides HP132, it also contains 0.2wt.% IRGANOX1010, 0.2wt.% IRGAFOS168, 0.03wt.% fatty acid salt and 0.04wt.% VITON FREEFLOW Z200 processing aid. Sample 2 except In addition to HP132, it also contains 0.2wt.% IRGANOX1010, 0.2wt.% IRGAFOS168, 0.03wt.% fatty acid salt, 0.04wt.% VITON FREEFLOW Z200 and 0.75wt.% ZnO. IRGANOX 1010 phenolic primary antioxidant for processing and long-term heat stabilization is a sterically hindered phenolic antioxidant, and IRGAFOS 168 is a hydrolytically stable phosphate processing stabilizer, both commercially available. Table 1 ...

Embodiment 2

[0102] The effect of ZnO concentration on the oxidation induction time of CWS-PCs of the type described herein was investigated. Determination of the OIT of the plaque (plaque) prepared by CWS-PC and in Figure 4 given in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com