anesthesia vaporizer

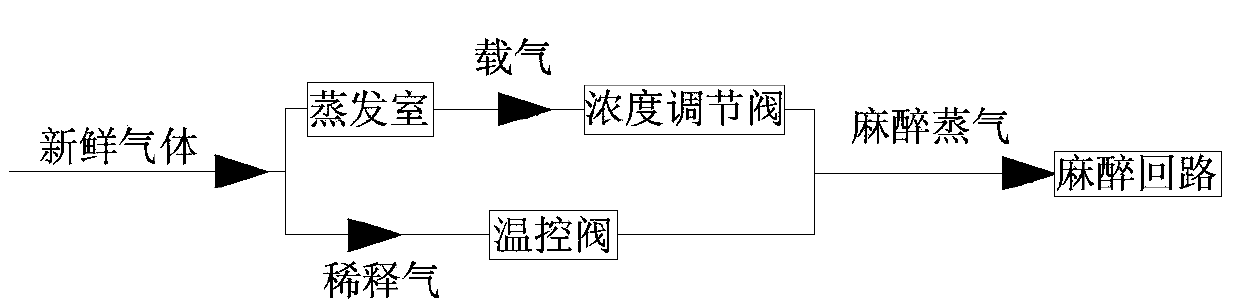

An anesthesia evaporator and evaporation chamber technology, applied in the field of anesthesia evaporators, can solve the problems of mixed anesthesia vapor concentration changes, untimely transmission of temperature, potential safety hazards, etc., to avoid leakage of anesthesia, stable and consistent concentration, and large opening and closing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

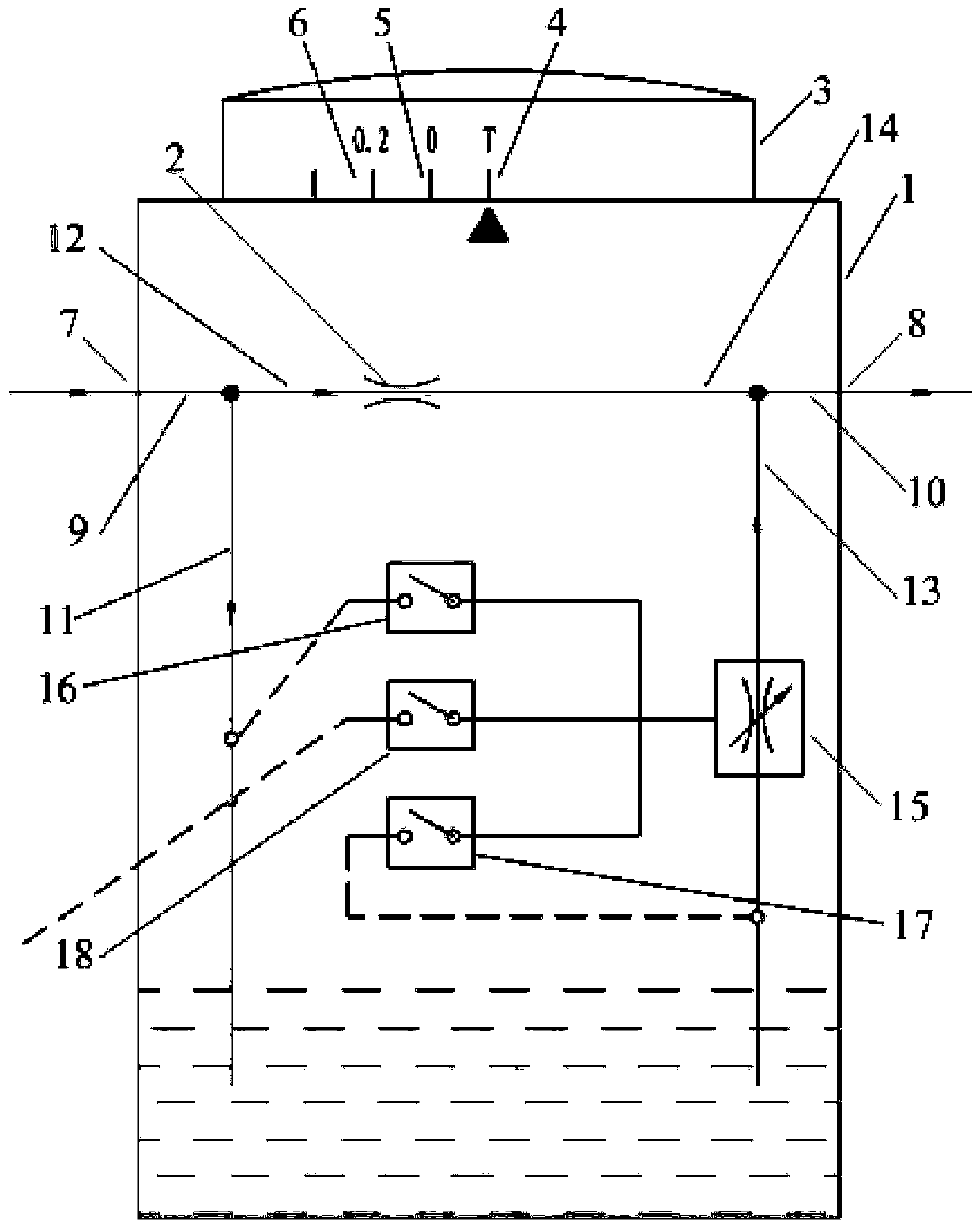

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0046] Such as figure 2 As shown, an anesthesia vaporizer includes an evaporation chamber 1, a dial 3, a temperature control valve 2 and a three-station switching device. The anesthesia vaporizer has a transport position 4, a zero position 5, a concentration position 6, and an evaporation chamber 1. It has a fresh gas inlet 7 and an anesthetic steam outlet 8. The evaporation chamber 1 is provided with a first gas path 9 connected to the fresh gas inlet 7 and a second gas path 10 connected to the anesthetic steam outlet 8. The first gas path 9 is evaporated The chamber 1 is branched into the first branch gas path 11 and the second branch gas path 12, and the third branch gas path 13 and the fourth branch gas path 14 are also set in the evaporation chamber 1, and the two branch gas paths are combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com