An activated carbon modification method that can effectively remove trace acid gases in the air

A technology of acid gas and activated carbon, applied in the field of ambient air purification, to achieve strong operability, few steps, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

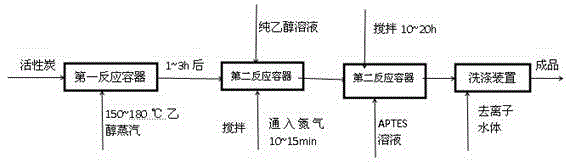

Method used

Image

Examples

Embodiment 1

[0020] Take 100g of activated carbon particles, put them in the reaction container, pass through the ethanol vapor at 160~180℃, the reaction time is 2~3h, and activate the activated carbon for the second time; then put the activated carbon after preliminary treatment into the Schlenk flask Add 500ml of pure ethanol solution, and pass nitrogen gas for 10~15min, and stir at the same time, so that no air remains in the flask; add 20g of 3-aminopropyltriethoxysilane (APTES) solution into the flask, and stir for 15h ; The treated activated carbon is separated by vacuum filtration, washed with deionized water and air-dried naturally, and the activated carbon after the treatment is packaged for use.

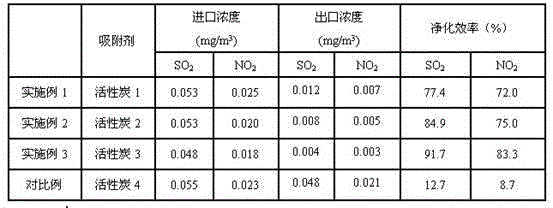

[0021] Take the prepared activated carbon 1, pass it into air, and carry out a static adsorption test to test its purification effect. The main consideration is the absorption of sulfur dioxide and nitrogen dioxide in the air by activated carbon. The size of the adsorption column is ?3...

Embodiment 2

[0023] Take 100g of activated carbon particles, put them in the reaction container, pass through the ethanol vapor at 160~180℃, the reaction time is 2~3h, and activate the activated carbon for the second time; then put the activated carbon after preliminary treatment into the Schlenk flask Add 500ml of pure ethanol solution, and feed nitrogen gas for 10~15min, and stir at the same time, so that no air remains in the flask; add 40g of APTES solution into the flask, stir for 15h; separate the treated activated carbon by vacuum filtration, and use Wash with deionized water and air-dry naturally, and the activated carbon after the treatment is packaged for use.

[0024] Take the prepared activated carbon 2, pass it into the air, and carry out a static adsorption test to test its purification effect. The main consideration is the absorption of sulfur dioxide and nitrogen dioxide in the air by activated carbon. The size of the adsorption column is ?35mm×150mm, the superficial gas v...

Embodiment 3

[0026] Take 100g of activated carbon particles, put them in the reaction container, pass through the ethanol vapor at 160~180℃, the reaction time is 2~3h, and activate the activated carbon for the second time; then put the activated carbon after preliminary treatment into the Schlenk flask Add 500ml of pure ethanol solution, and feed nitrogen gas for 10~15min, while stirring, so that there is no residual air in the flask; add 60g of APTES solution into the flask, stir for 15h; separate the treated activated carbon by vacuum filtration, and use Wash with deionized water and air-dry naturally, and the activated carbon after the treatment is packaged for use.

[0027] Take the prepared activated carbon 3, pass it into the air, and carry out a static adsorption test to test its purification effect. The main consideration is the absorption of sulfur dioxide and nitrogen oxides in the air by activated carbon. The size of the adsorption column is ?35mm×150mm, the superficial gas vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com