A method for preparing a high-density and low-resistivity zinc oxide ceramic target

A ceramic target and resistivity technology, which is applied in the field of preparation of high-density and low-resistivity zinc oxide ceramic targets, can solve problems such as reducing the density of the target and generating pores in the target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

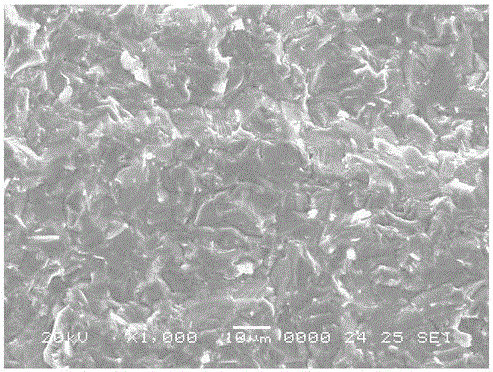

Embodiment 1

[0017] According to Al 2 o 3 / (ZnO+Al 2 o 3 ) with a mass ratio of 2% to weigh zinc oxide powder (D50=400nm) and alumina powder (D50=100nm), with a total mass of 200 grams. Bi 2 o 3 As a sintering aid, the addition amount is 0.02% of the total weight of doped ZnO powder. Add anhydrous alcohol for ball milling. The ball milling time is 6 hours. After ball milling, dry at 80°C. Add 30ml of polyvinyl alcohol (PVA) aqueous solution with a mass ratio of 5% to the dry mixed powder, and add PVA to the wet powder. The body was dried, and then sieved with a 100-mesh stainless steel screen. The granulated powder was pressed into a green compact of Φ35×10mm by cold isostatic pressing (CIP), and fired at 1400°C for 4 hours to obtain a target with a density of 99.8% and a resistivity of 4.5mΩ·cm.

Embodiment 2

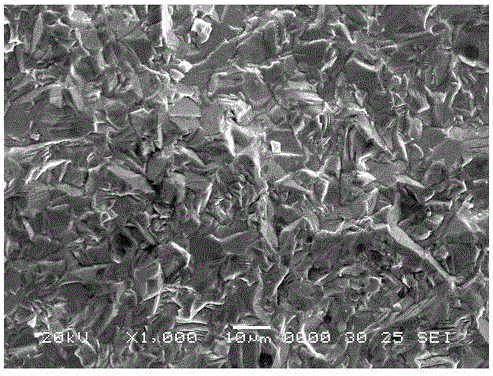

[0019] According to Ga 2 o 3 / (ZnO+Ga 2 o 3 ) with a mass ratio of 6% to weigh zinc oxide powder (D50=800nm) and gallium oxide powder (D50=160nm), with a total mass of 200 grams. B 2 o 3 As a sintering aid, the addition amount is 0.06% of the total weight of doped ZnO powder. Add anhydrous alcohol for ball milling. The ball milling time is 6 hours. After ball milling, dry at 80°C. Add 30ml of polyvinyl alcohol (PVA) aqueous solution with a mass ratio of 5% to the dry mixed powder, and add PVA to the wet powder. The body was dried, and then sieved with a 100-mesh stainless steel screen. The granulated powder was pressed into a green compact of Φ35×10mm by cold isostatic pressing (CIP), and fired at 1400°C for 4 hours to obtain a target with a density of 99.7% and a resistivity of 4.1mΩ·cm.

Embodiment 3

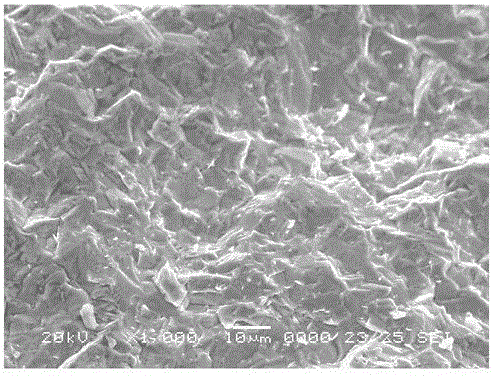

[0021] Follow In 2 o 3 / (ZnO+In 2 o 3 ) with a mass ratio of 3% to weigh zinc oxide powder (D50=550nm) and indium oxide powder (D50=210nm), with a total mass of 200 grams. SiO 2 As a sintering aid, the addition amount is 0.04% of the total weight of doped ZnO powder. Add anhydrous alcohol for ball milling. The ball milling time is 6 hours. After ball milling, dry at 80°C. Add 30ml of polyvinyl alcohol (PVA) aqueous solution with a mass ratio of 5% to the dry mixed powder, and add PVA to the wet powder. The body was dried, and then sieved with a 100-mesh stainless steel screen. The granulated powder was pressed into a green compact of Φ35×10mm by cold isostatic pressing (CIP), and fired at 1400°C for 4 hours to obtain a target with a density of 99.8% and a resistivity of 4.8mΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com