Water-solubility instant potassium sulfate fertilizer

An instant potassium sulfate, water-soluble technology, applied in potash fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of slow dissolution rate, high content of water-insoluble substances, corrosion, etc., to avoid clogging drippers and nozzles, and avoid pipeline knots Scale and corrosion, the effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

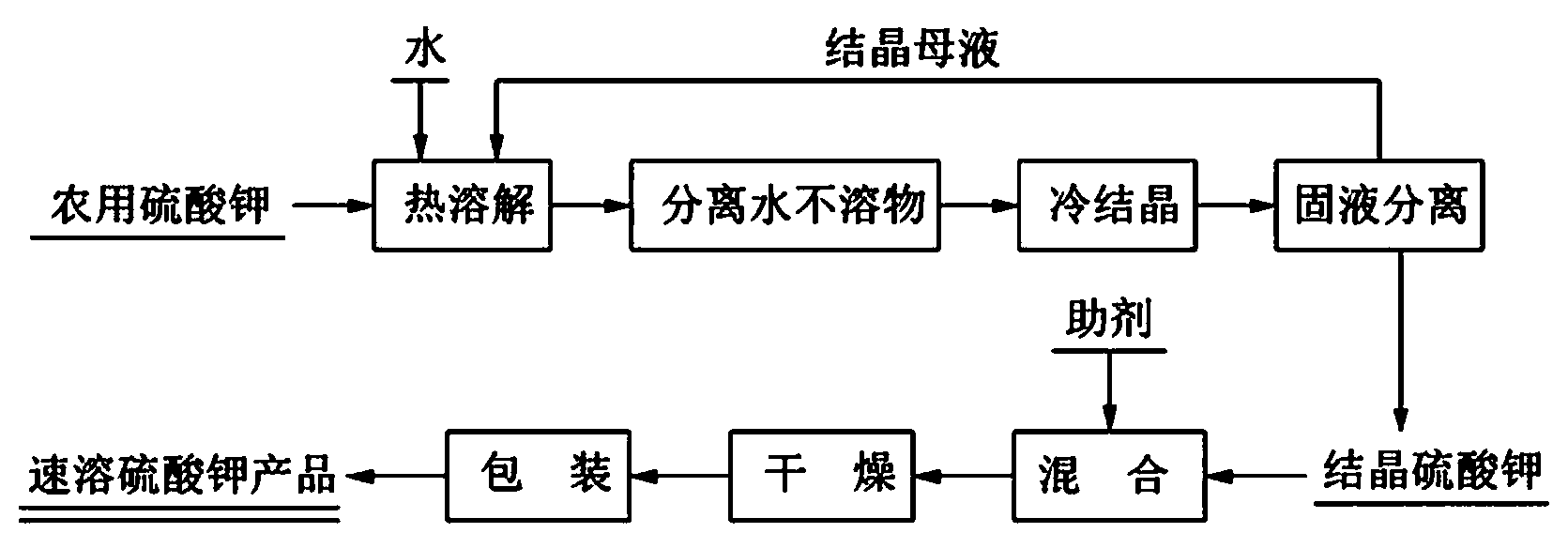

[0029] (1) if figure 1 As shown, according to the liquid-solid ratio of 4.5:1, put the agricultural potassium sulfate and tap water into the dissolution tank, and heat-dissolve at 80°C for 10 minutes;

[0030] (2) The centrifuge separates the water-insoluble matter, the solution enters the crystallizer for forced cooling and crystallization, the crystallization end point temperature is 20°C, the solid-liquid separation obtains crystalline potassium sulfate, the particle size is less than 0.3mm, accounting for 88.64%, and the crystallization mother liquor returns to the step ( 1) Recycled as a solvent;

[0031] (3) According to the weight ratio of 95% crystalline potassium sulfate, 1% component A, 4% component B and 0% component C, feed in a double-helix conical mixer for mechanical mixing;

[0032] (4) After mixing, it enters the drying process and is packaged as an instant potassium sulfate product, K 2 The O content is 51.3%, and the water-insoluble content is 0.018%.

Embodiment 2

[0034] (1) if figure 1 As shown, according to the liquid-solid ratio of 11.8:1, the agricultural potassium sulfate and the crystallization mother liquor are metered into the dissolution tank, and thermally dissolved at 85°C for 15 minutes;

[0035] (2) The centrifuge separates the water-insoluble matter, the solution enters the crystallizer for forced cooling and crystallization, the crystallization end point temperature is 25°C, the solid-liquid separation obtains crystalline potassium sulfate, the particle size is less than 0.3mm, accounting for 85.73%, and the crystallization mother liquor returns to the step ( 1) Recycled as a solvent;

[0036] (3) According to the weight ratio of 95.5% crystalline potassium sulfate, 0.5% component A, 3% component B and 1% component C, feed in a horizontal ribbon mixer for mechanical mixing;

[0037] (4) After mixing, it enters the drying process and is packaged as an instant potassium sulfate product, K 2 The O content is 51.5%, and the...

Embodiment 3

[0039] (1) if figure 1 As shown, according to the liquid-solid ratio of 10.8:1, the agricultural potassium sulfate and the dissolving agent (a mixture of tap water and crystallization mother liquor) are metered into the dissolving tank, and thermally dissolved at 95°C for 20 minutes;

[0040] (2) The centrifuge separates the water-insoluble matter, the solution enters the crystallizer for forced cooling and crystallization, the crystallization end point temperature is 30°C, solid-liquid separation obtains crystalline potassium sulfate, the particle size is less than 0.3mm, accounting for 78.54%, and the crystallization mother liquor returns to the step ( 1) Recycled as a solvent;

[0041] (3) According to the weight ratio of 96.0% crystalline potassium sulfate, 1.5% component A, 2% component B and 0.5% component C, feed in a horizontal ribbon mixer for mechanical mixing;

[0042] (4) After mixing, it enters the drying process and is packaged as an instant potassium sulfate pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com