Waterproof sealing material for home decoration

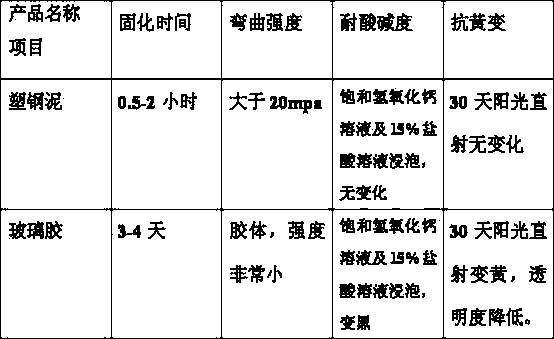

A technology for waterproof sealing and home decoration, applied in the direction of epoxy resin glue, adhesive type, adhesive additives, etc., can solve the problems of irritating odor, blackening, acid and alkali resistance, etc., and achieve obvious beautification effect, Obvious advantages and the effect of meeting the needs of high-quality decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The mass composition of each component is as follows:

[0043] A component:

[0044] Epoxy resin R139 60 parts

[0045] Calcium carbonate 15 parts

[0046] Fumed silica 4 parts

[0047] Titanium dioxide 20 parts

[0048] 1 part tributyl citrate

[0049] Component B:,

[0050] 60 parts of N-aminoethylpiperazine

[0051] Calcium carbonate 20 parts

[0052] Fumed silica 4 parts

[0053] Titanium dioxide 15 parts

[0054] 1 part benzyl alcohol

[0055] The production method is to mix and stir the epoxy resin with the brand name R139 and tributyl citrate for 15 minutes, add calcium carbonate and titanium dioxide three times, each interval is 20 minutes, the dispersion speed is 300-500 rpm, add gas phase white Carbon black, disperse and stir for 30 minutes, evacuate for 30 minutes, vacuum degree 0.06-0.09mpa, discharge and pack, this is component A. Mix and stir N-aminoethylpiperazine and benzyl alcohol for 15 minutes, add calcium carbonate and titanium dioxide thr...

Embodiment 2

[0058] A component:

[0059] Epoxy resin R140 70 parts

[0060] Barium sulfate 30 parts

[0061] Fumed silica 5 parts

[0062] Titanium dioxide 25 parts

[0063] Ethyl tributyl citrate 2 parts

[0064] B component:

[0065] 1,3-Diaminomethylcyclohexane 60 parts

[0066] Calcium carbonate 20 parts

[0067] Fumed silica 4 parts

[0068] Titanium dioxide 15 parts

[0069] 1 part benzyl alcohol

[0070] Repeat the method of Example 1 according to the content of each component specified in the above, but replace the epoxy resin of R139 with the epoxy resin of R140, replace calcium carbonate with barium sulfate, and replace with ethyl tributyl citrate Tributyl citrate with 1,3-diaminomethylcyclohexane instead of N-aminoethylpiperazine. The test results are as follows:

[0071] Tensile strength (GB / T2568-1995) 11.8 MPa BaiDu 92 acid and alkali resistance Soak in saturated calcium hydroxide solution and 15% hydrochloric acid solution, no c...

Embodiment 3

[0073] A component:

[0074] Epoxy resin R142 100 parts

[0075] Aluminum oxide 50 parts

[0076] Fumed silica 7 parts

[0077] Titanium dioxide 30 parts

[0078]5 parts triethyl citrate

[0079] B component:

[0080] TAC cycloaliphatic amine 95 parts

[0081] Aluminum oxide 35 parts

[0082] Fumed silica 5 parts

[0083] Titanium dioxide 30 parts

[0084] 5 parts benzyl alcohol

[0085] Repeat the method of Example 1 according to the content of each component specified in the above, but replace the epoxy resin of R140 with the epoxy resin of R142, replace barium sulfate with aluminum oxide, and replace citric acid with triethyl citrate Tributyl ester, replace 1,3-diaminomethylcyclohexane with TAC cycloaliphatic amine. The test results are as follows:

[0086] Tensile strength (GB / T2568-1995) 12.5MPA BaiDu 90 acid and alkali resistance Soak in saturated calcium hydroxide solution and 15% hydrochloric acid solution, no change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com