High-efficiency continuous casting method of structure-controllable closed cell foam aluminum ingot

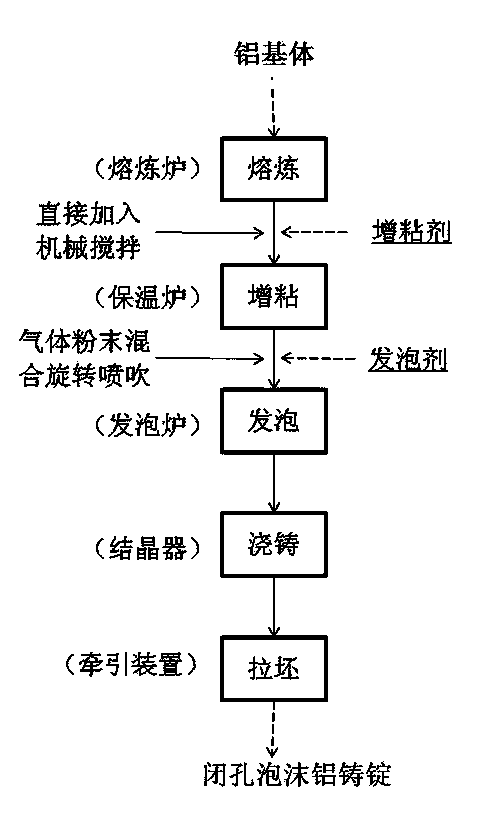

A closed-cell aluminum foam, high-efficiency technology, applied in the field of high-efficiency continuous casting, can solve the problems of complex equipment and process, low efficiency, not continuous casting, etc., to reduce equipment requirements and operation difficulty, small bubble size, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The detailed process of the continuous casting method of closed-cell aluminum foam and aluminum alloy is as follows:

[0036] Preparatory process: preheating the holding furnace, foaming furnace, agitator, and segmental holding crystallizer; checking the transfer mechanism of the melt in the melting furnace to the intermediate holding furnace, the transfer mechanism of the intermediate holding furnace to the foaming furnace, The operation of the traction roller and the driving device of the dummy bar.

[0037] Implementation example 1:

[0038] First, heat and melt the metal aluminum substrate in the melting furnace. After the slag removal and refining treatment, transfer it to the holding furnace through the transfer and dumping mechanism to keep it warm. Set the holding temperature to 750 ° C. When the temperature is constant at 750 ± 5 ° C Add 3.5wt.% calcium block tackifier to the aluminum melt. The calcium block needs to be wrapped with aluminum foil first. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com