Method for improving hole sealing performance in gas extraction

A technology of gas drainage and airtightness, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of low gas drainage concentration, low drainage efficiency, and reduce the decay speed of gas concentration, so as to improve the utilization High efficiency, broad application prospects, and the effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0024] A kind of method for improving the airtightness of gas drainage sealing hole of the present embodiment comprises the following steps:

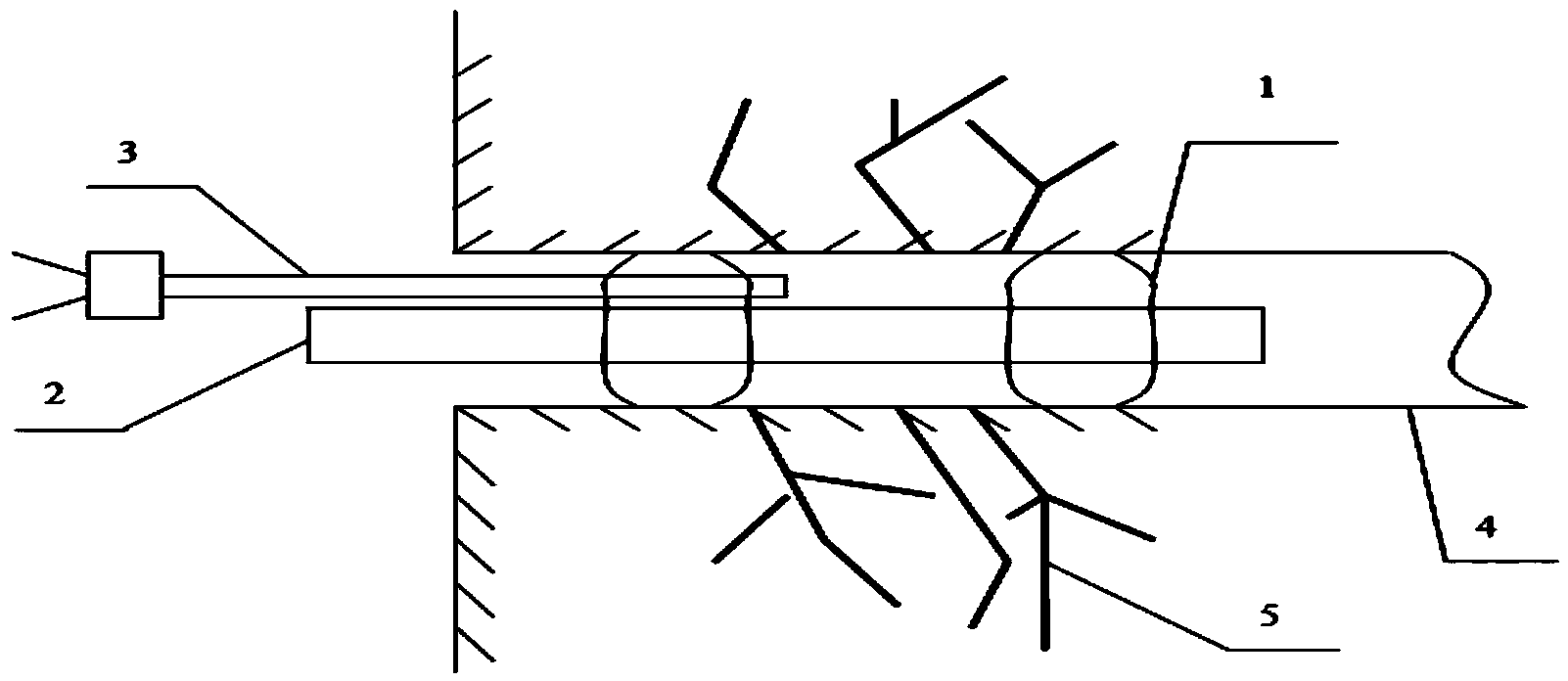

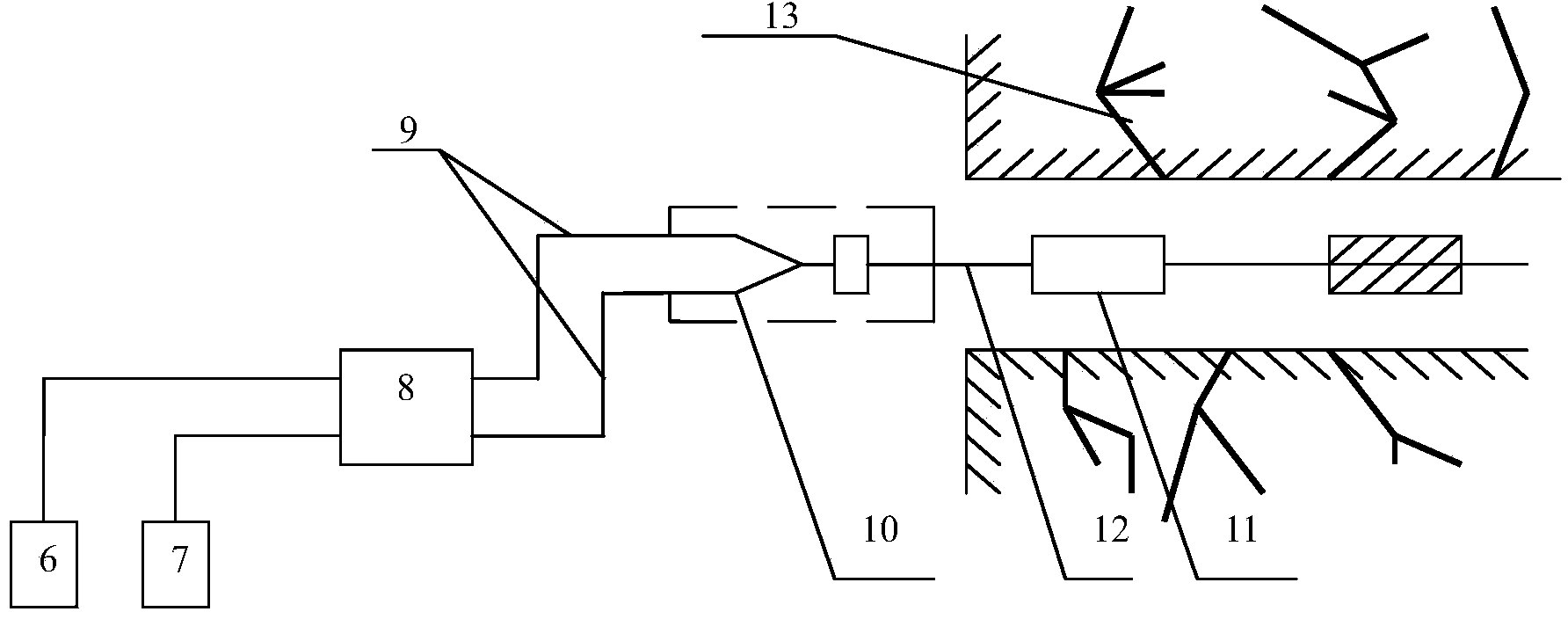

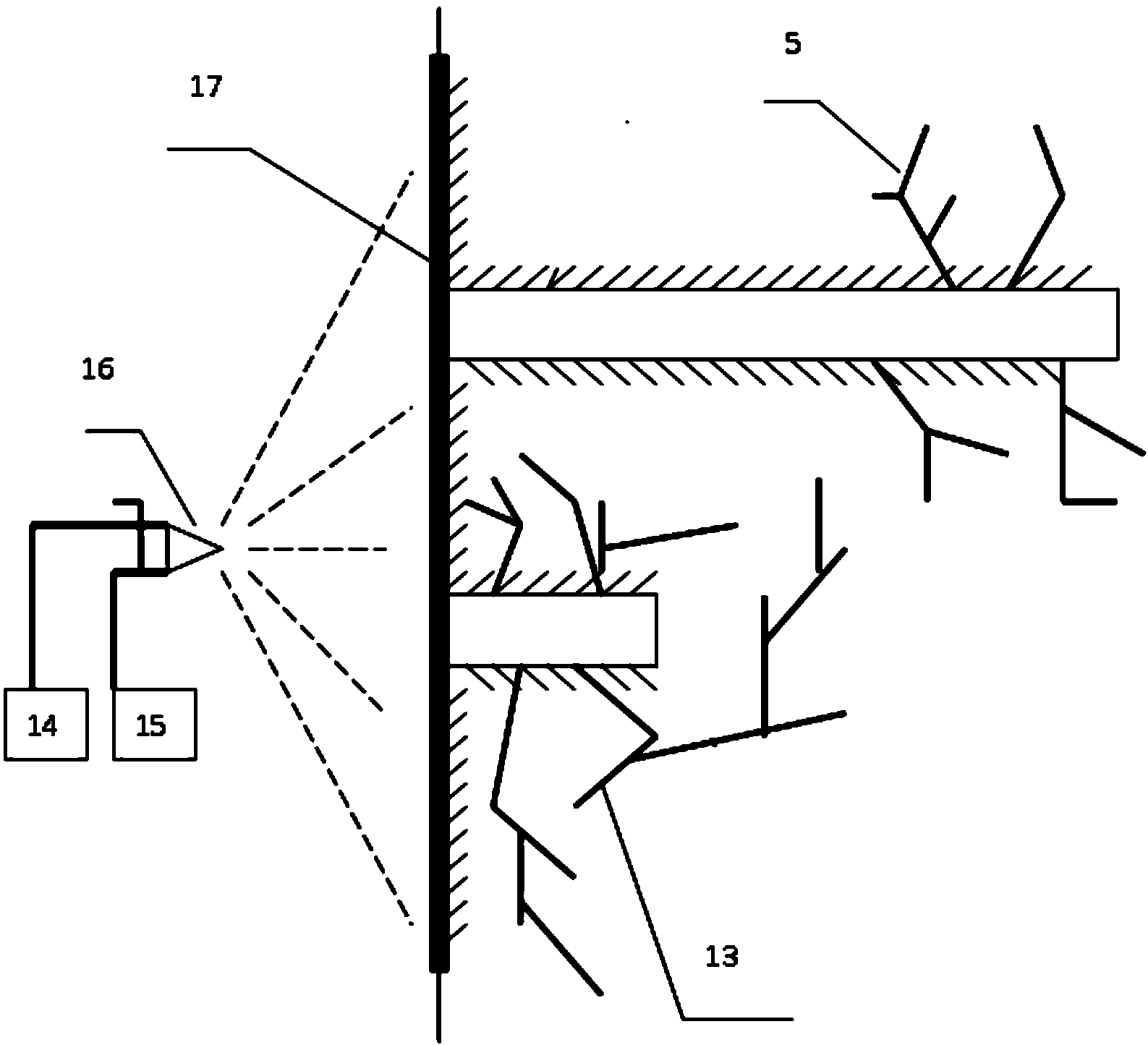

[0025] Step 1: Use sealing material to seal the drilling sealing section and the cracks generated by drilling vibration;

[0026] The second step: using reinforcement materials to reinforce and seal the cracks in the loose coal and rock mass near the drilling sealing section;

[0027] The third step: use the spraying material to spray the surface of the coal wall near the hole opening of the drilling hole sealing section.

[0028] In this embodiment, the method of combining the three processes of sealing, reinforcement and spr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap