Maximum power point tracking method for wind power generation system based on Boost convertor

A technology of wind power generation system and maximum power point, which is applied in the direction of wind power generation, wind engine, wind engine control, etc., can solve the problems of increasing actual cost, reducing wind energy conversion efficiency, and slow response speed, so as to improve power quality and reduce Application cost, effect of suppressing power disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

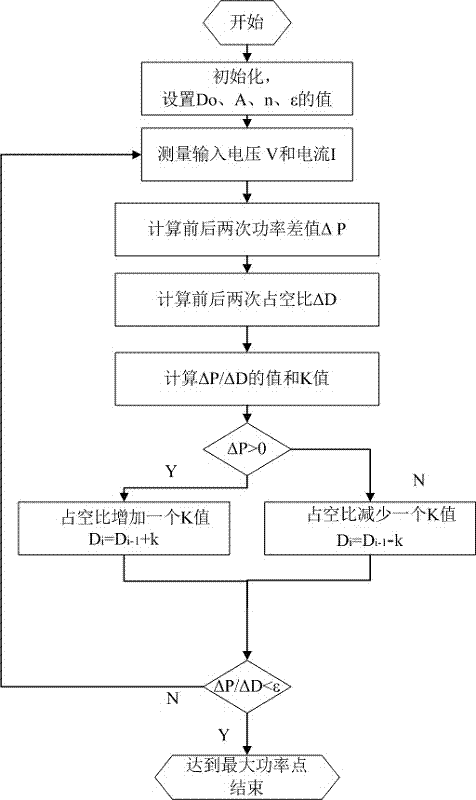

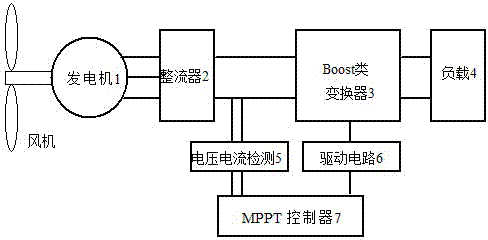

[0017] see figure 1 , the present embodiment is based on the method for tracking the maximum power point of a wind power generation system with a Boost type converter, which is characterized in that in the Boost type converter circuit, the output power of the generator is controlled by changing the circuit duty ratio, and the specific operation steps are as follows:

[0018] a. System initialization, set tracking error , respectively measure the input voltage and current of the Boost converter circuit twice before and after the sampling period, calculate the input power, and calculate the power difference between the two times before and after?P;

[0019] b. Obtain the duty cycle of the converter at the two sampling times from the controller MCU, and calculate the duty cycle difference ?D;

[0020] c. Determine the change direction of the duty cycle according to the positive or negative of the power difference ?P. If ?P>0, the duty cycle increases by one tracking st...

Embodiment 2

[0022] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special feature is: the variable step size variation K is:

[0023]

[0024] In the formula: the step size variation K, D is the circuit duty cycle, A is the step size disturbance factor, n is the step size attenuation factor, e is the natural logarithm, the power difference between the two samples before and after? P, the two samples before and after Duty cycle difference?D.

Embodiment 3

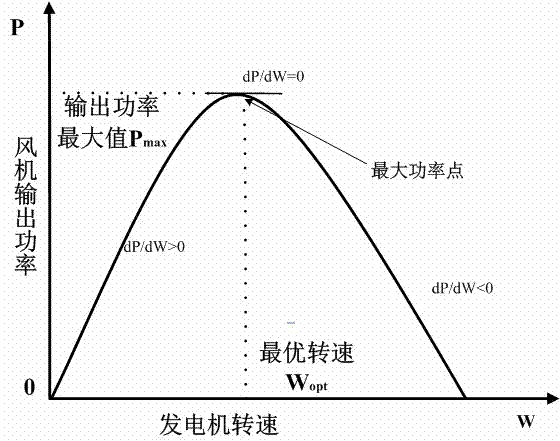

[0026] This embodiment is based on the maximum power point tracking method of the wind power generation system based on the Boost converter, and its theoretical basis is as follows:

[0027] When the wind turbine system operates at the maximum power point, the power generation system such as figure 2 As shown, the relationship between fan power and fan speed is as follows:

[0028] (1)

[0029] Expand to get:

[0030] (2)

[0031] In the formula: - fans capture power, - Fan mechanical angular velocity, D-Boost circuit duty cycle, -Boost circuit input voltage, - Generator phase voltage angular velocity.

[0032] In a Boost circuit, the input voltage and output voltage The following relationship exists:

[0033] (3)

[0034] (4)

[0035] The relationship between the mechanical angular velocity of the fan and the angular velocity of the phase voltage of the generator is as follows:

[0036] (5)

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com