Pneumatic type automatic control three-way valve

A three-way valve, pneumatic technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of increasing investment and operation and maintenance costs, reducing system operation reliability, and complicating the control system, so as to reduce investment and operation and maintenance costs, simple structure, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

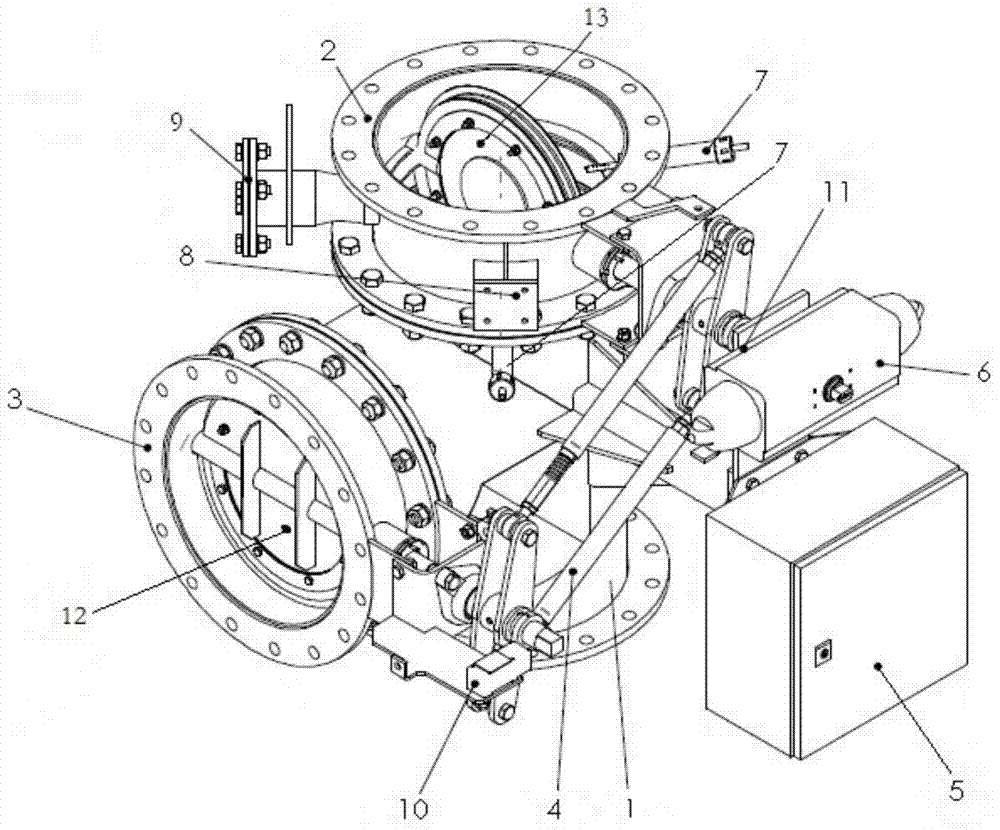

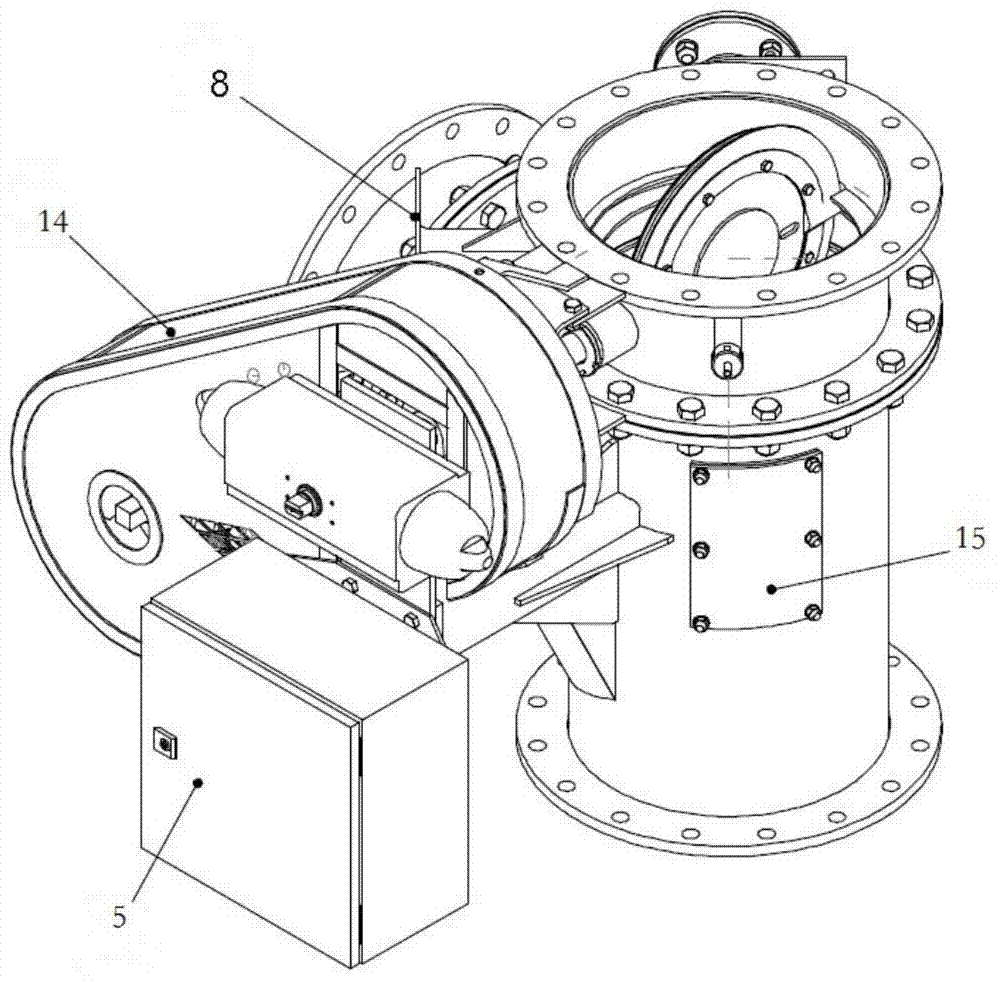

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

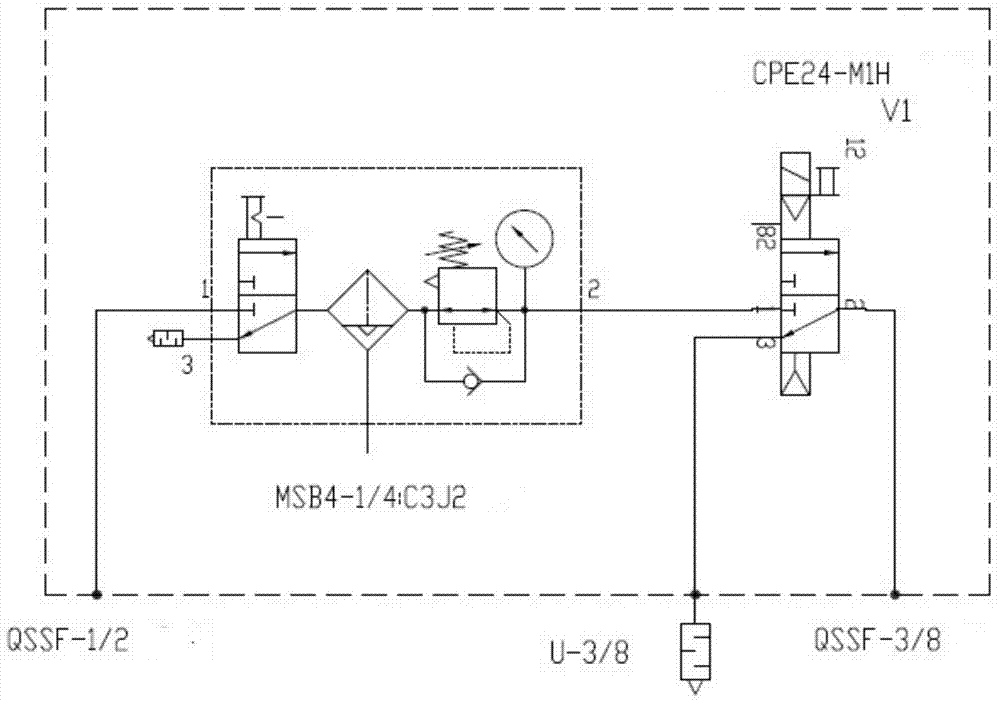

[0017] combine Figure 1~3 , the pneumatic automatic control three-way valve consists of valve T-shaped frame 1, detachable baffle seat 2, 3, single sealing baffle 12, double sealing baffle 13, position switch 10, pneumatic actuator 6, pneumatic actuator The installation frame 11, the pressure measuring tube 7, the pressure gauge support frame 8, the inspection window 15, the actuator 4, the sealing air interface 9, the valve protection cover 14 and the control box 5 are composed.

[0018] The side outlet of the valve is at a 90° angle to the center line of the top outlet. The detachable baffle seat 2 and 3 are connected to the top and side of the valve T-frame 1 with bolts, the double-sealed baffle 13 is installed in the upper baffle seat 2, and the guide rod is perpendicular to the plane where the valve T-frame 1 is located. The single sealing baffle 12 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com