Method for freezing and vacuum-drying micro-nanopowder slurry

A freeze-vacuum drying, micro-nano technology, used in drying solid materials, method combination to dry solid materials, drying and other directions, can solve the problem of too wide, small as a few nanometers, as large as tens of micrometers or even hundreds of micrometers, unfavorable. Product application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings. However, it should be understood that the present invention is not limited to the content described below, and all modifications and changes made without violating the spirit or scope of the present invention belong to the scope of the present invention.

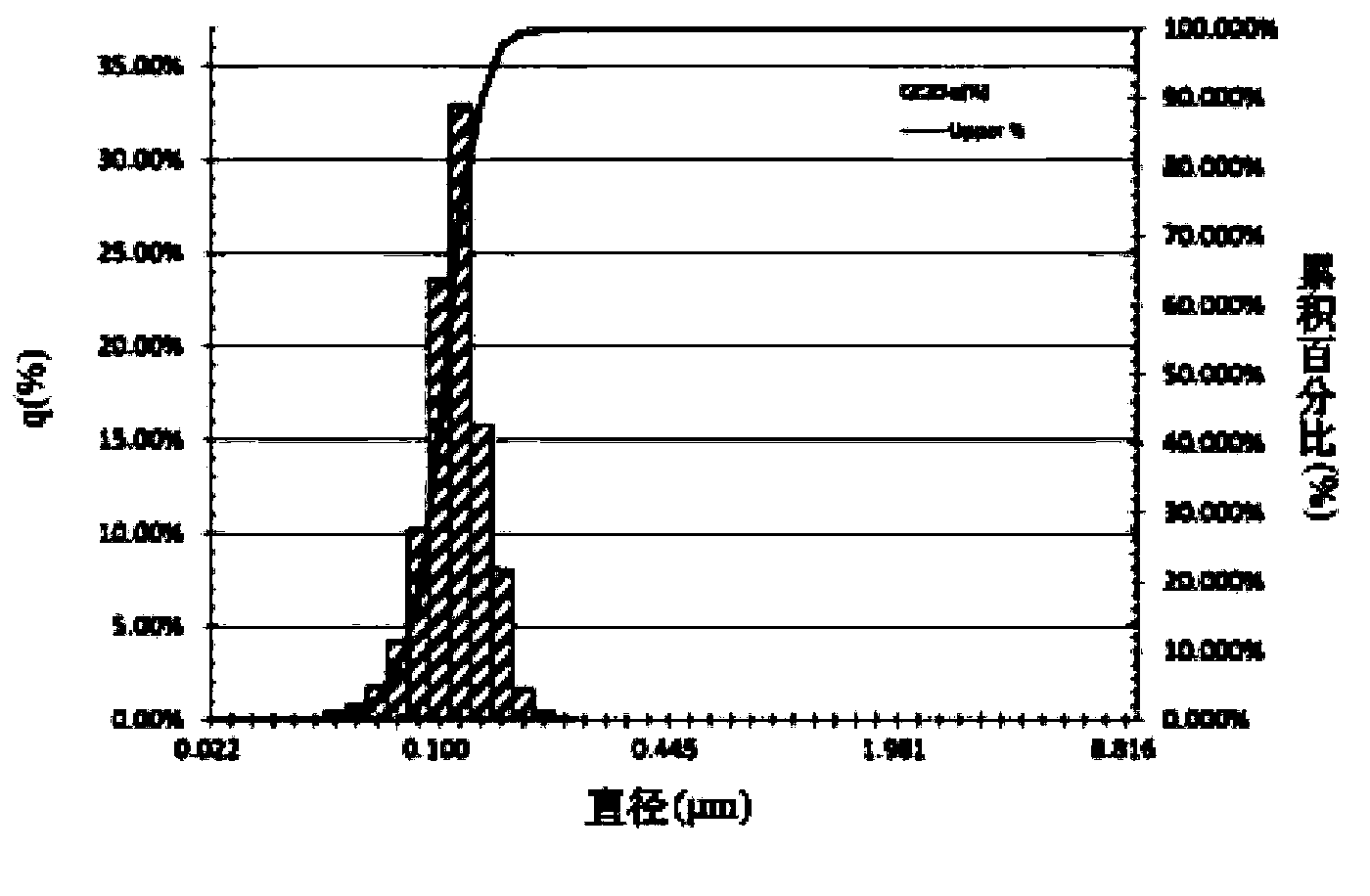

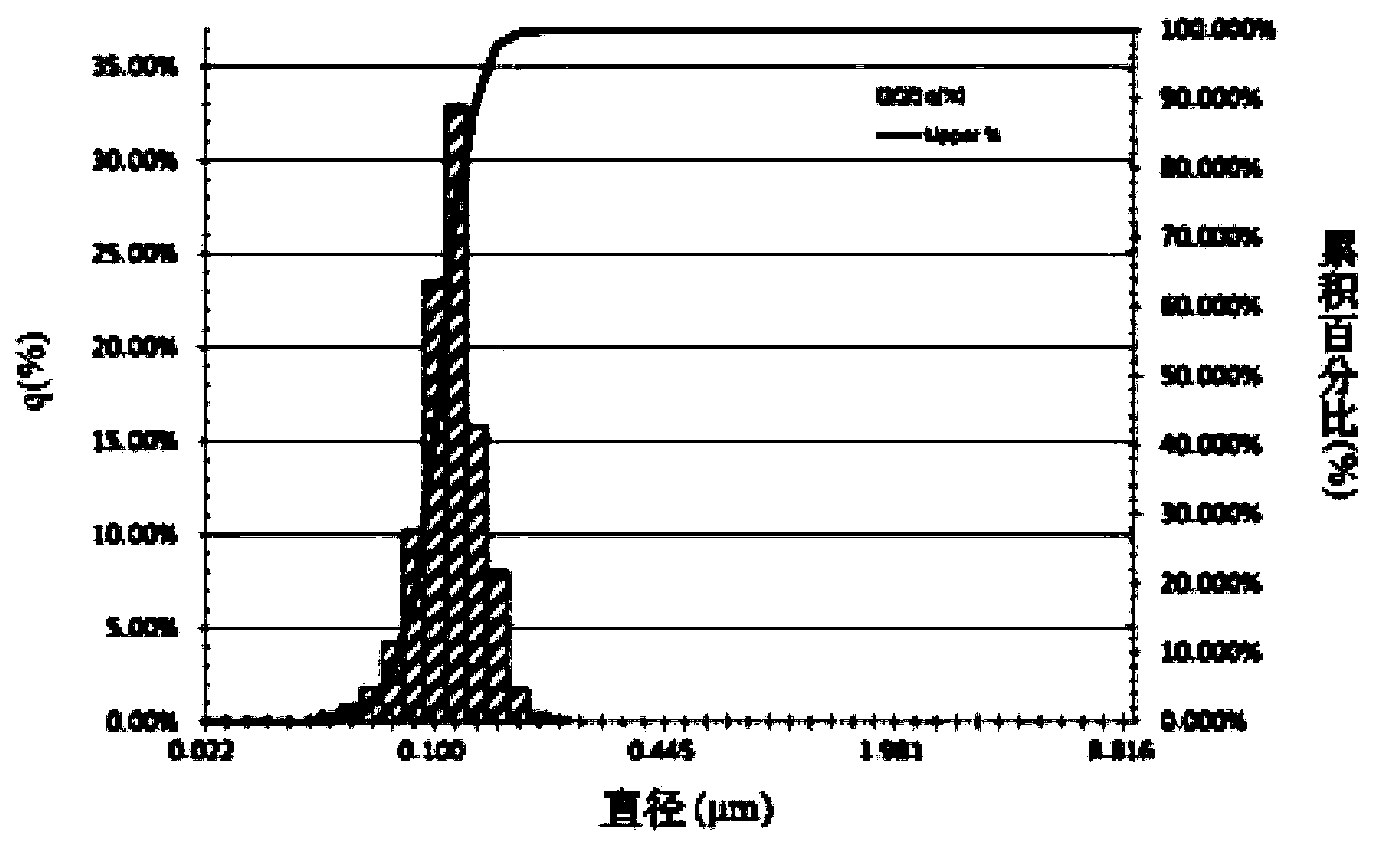

[0029] The freeze-vacuum drying method of the micro-nano powder slurry provided by the present invention mainly includes the following steps, wherein the micro-nano powder can be but not limited to bamboo charcoal powder, activated carbon powder, coffee charcoal powder or coconut charcoal powder:

[0030] The first cooling step: put a tray containing a micro-nano powder slurry with a solid content of 20wt% to 30wt% into a closed cavity, and cool the micro-nano powder slurry to -11°C to - At 13°C, the micro-nano powder slurry contains a dispersant and a wetting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com