Imaging spectrometer beam splitting system based on free-form surface

An imaging spectrometer and spectroscopic system technology, which is applied in the directions of spectrometry/spectrophotometry/monochromator, instruments, scientific instruments, etc. and other problems to achieve the effect of improving imaging quality, simplifying design and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

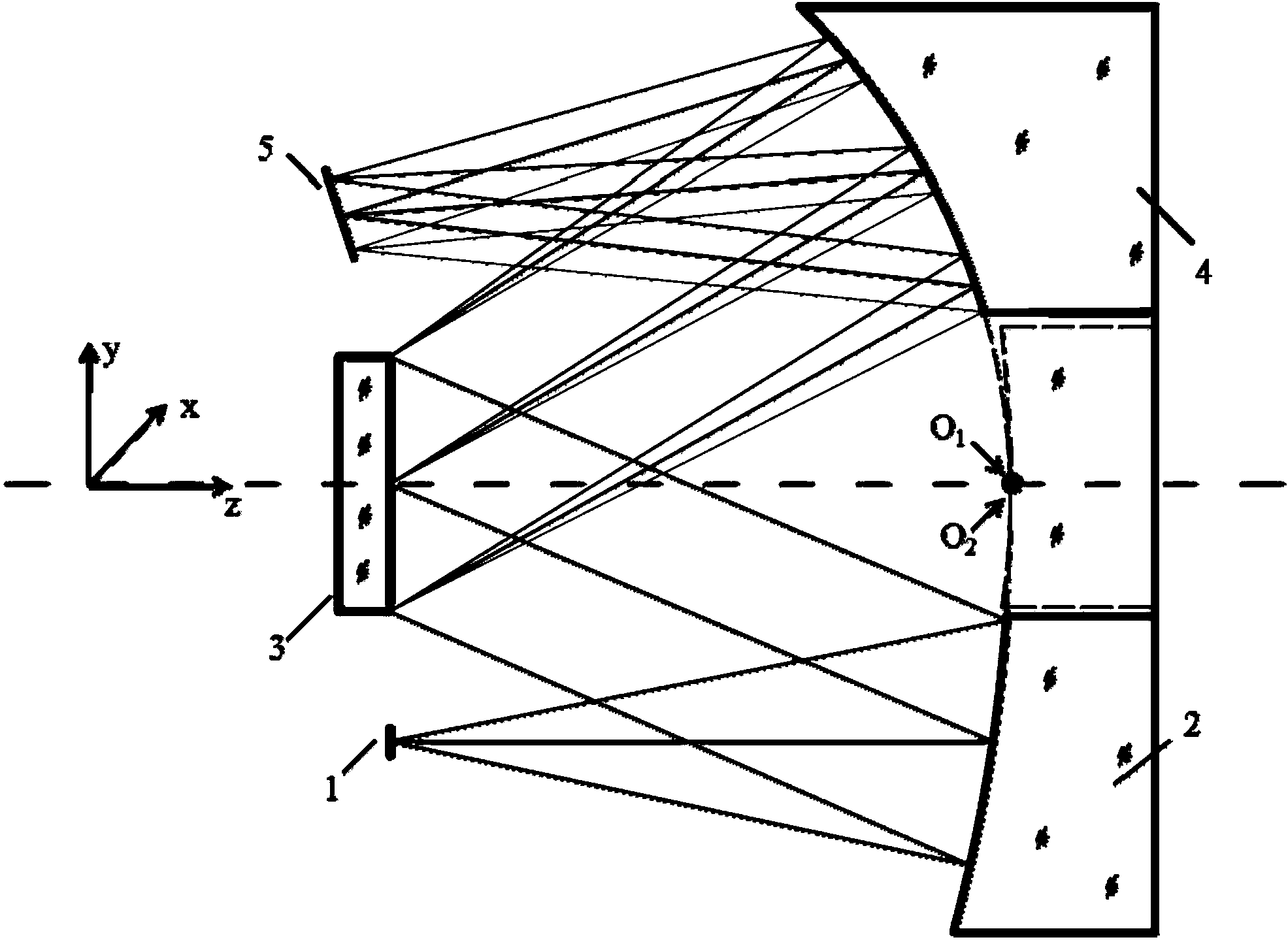

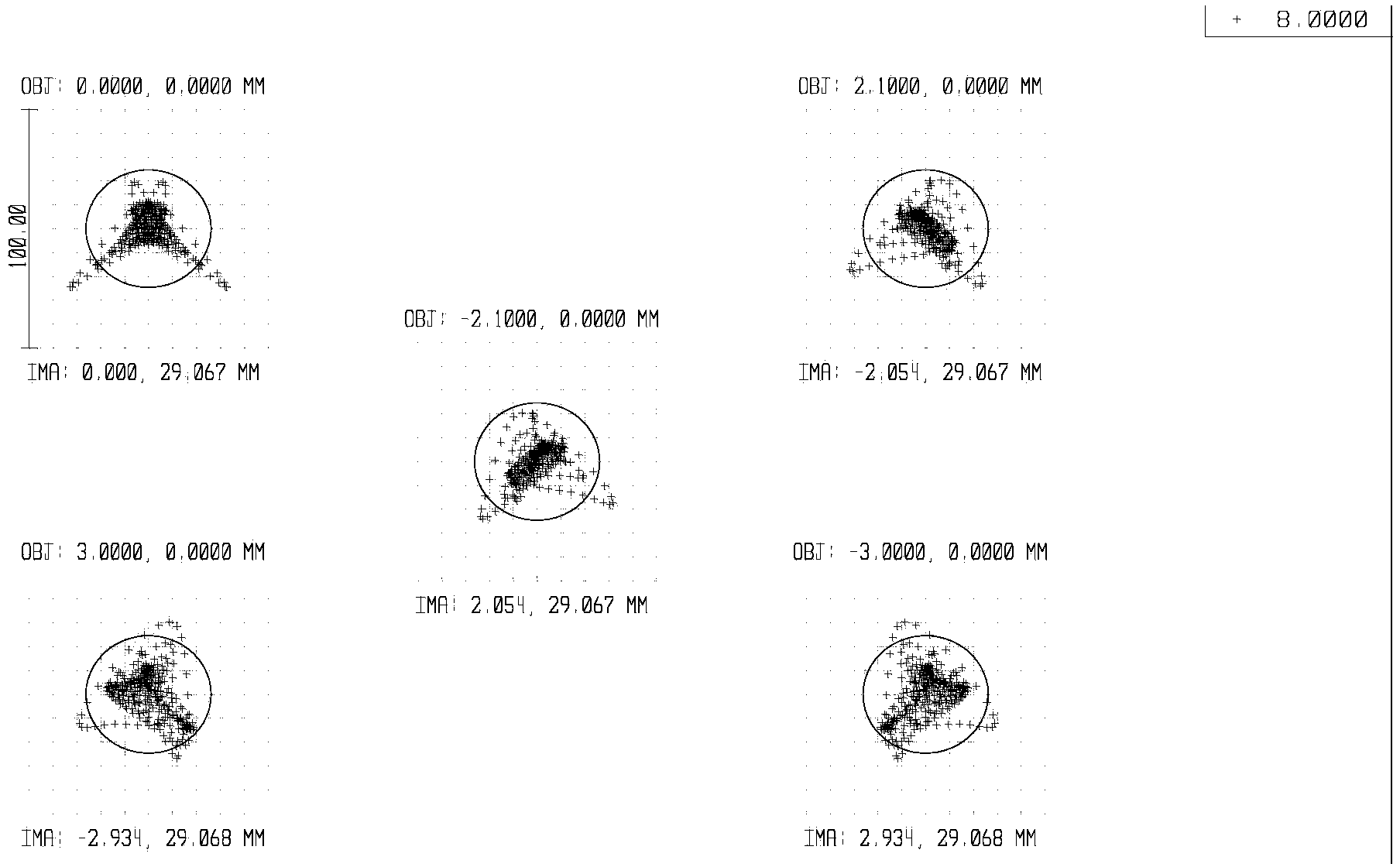

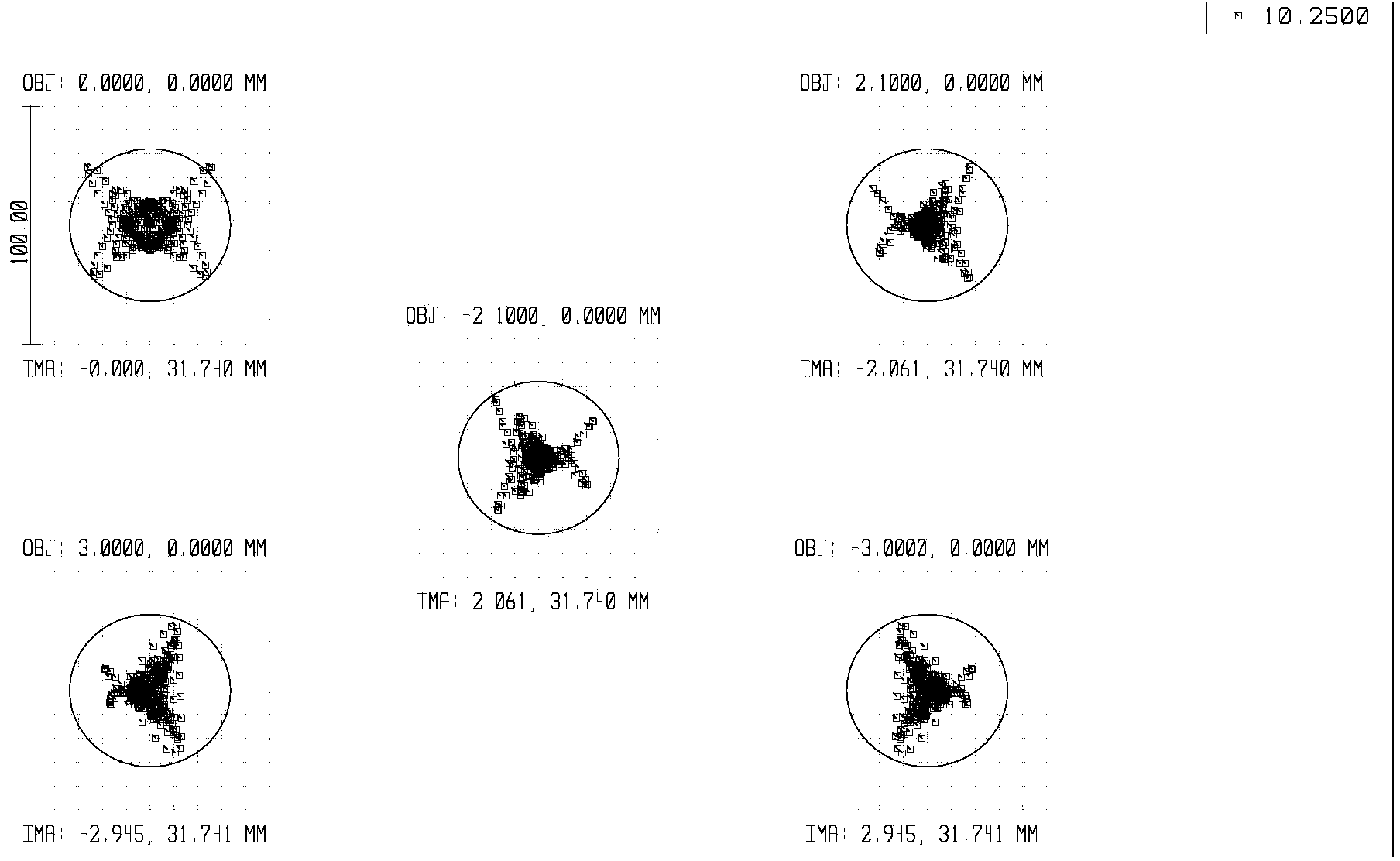

[0025] Such as figure 1 As shown, the spectrometer light-splitting system of the present invention takes the high-performance, simple-structured convex grating Offner structure and the Czerny-Turner structure based on the planar grating as design prototypes, takes the advantages of the two, avoids its shortcomings, and realizes in components and structures High-performance light splitting under the premise of simplicity. The spectroscopic system includes a slit 1 , a collimating free-form surface mirror 2 , a diffraction grating 3 , an imaging free-form surface mirror 4 and an image plane detector 5 . The slit 1 is the focal plane of the front telescopic objective lens, and the incident beam from a distant target is imaged on the slit through the telescope, which is used as the object plane of the spectroscopic system; the collimating free-form surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com