Control system for measuring device for accuracy retention of rolling functional parts of machine tools

A technology for maintaining accuracy and measuring devices, which can be used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., and can solve problems such as power loss, measurement efficiency and limited actual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1 A control system for a measuring device for accuracy retention of rolling functional parts of a machine tool, which measures the accuracy retention of rolling functional parts of a machine tool based on the measuring device for accuracy retention of rolling functional parts of a machine tool;

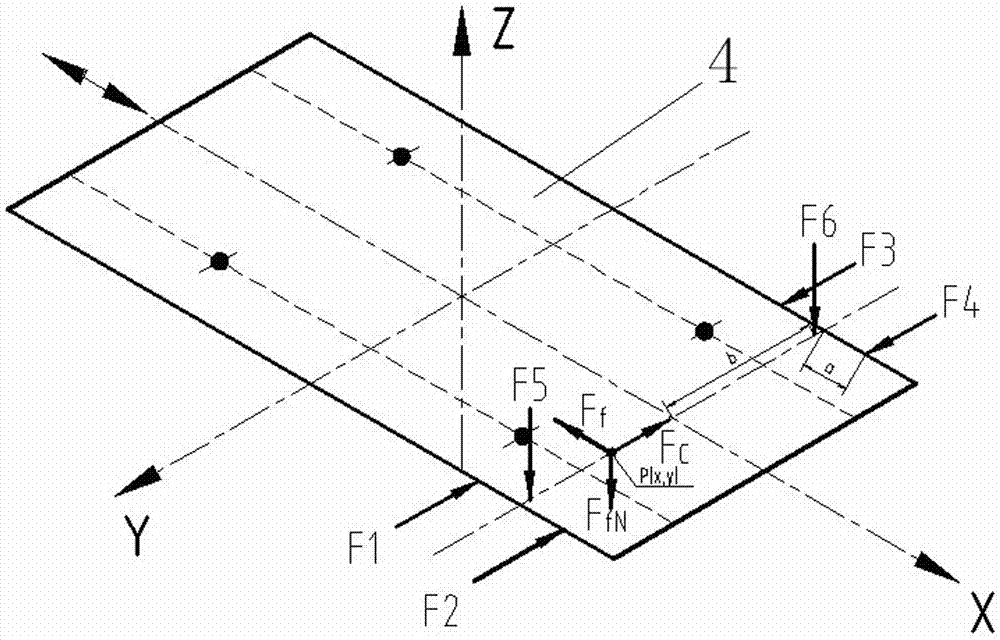

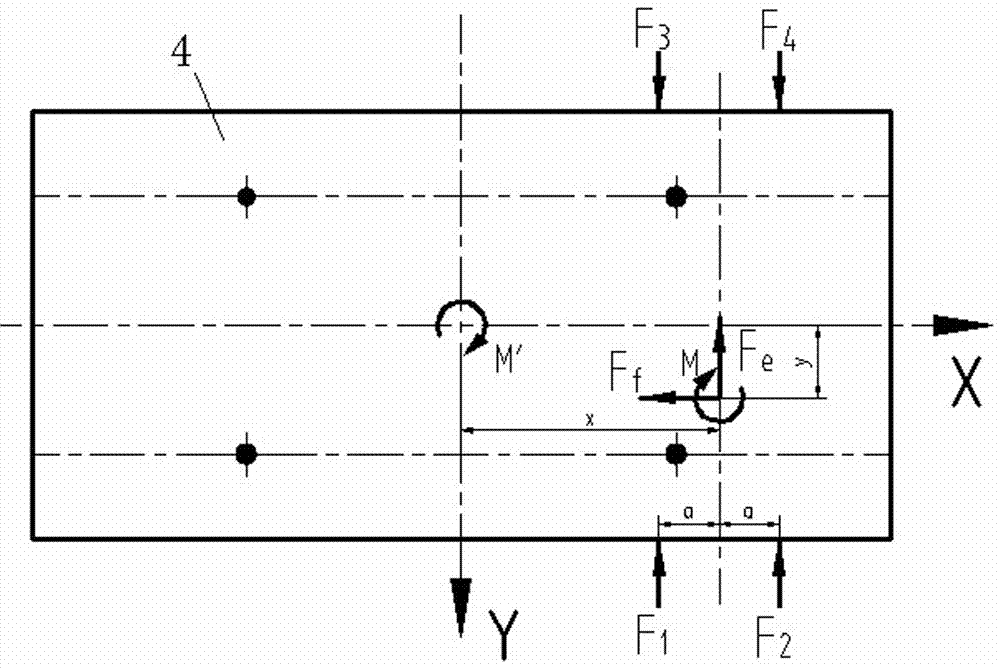

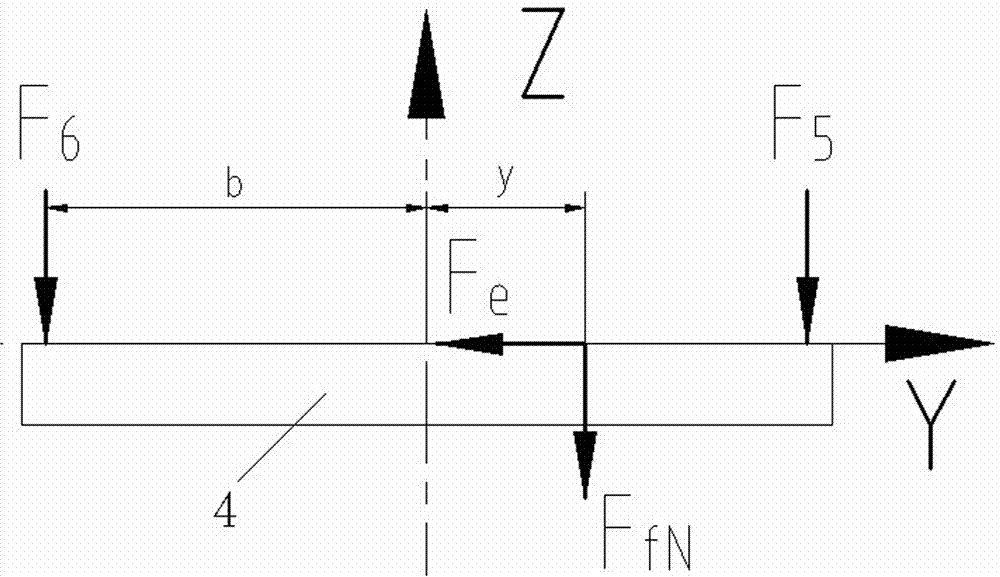

[0077] (1) The measuring device for accuracy retention of machine tool rolling function parts is composed of the following: bed 1, tested guide rail 2, tested screw 3, workbench 4, servo motor for screw 5, coupling for screw 6, implement The force component 7; wherein: the bed 1 is a horizontal structure; the tested guide rails 2 are two arranged parallel to each other in the horizontal direction, and are fixedly arranged on the upper part of the bed 1; the tested screw 3 is driven by its dedicated driving component; The workbench 4 is arranged on the tested guide rail 2 and the workbench 4 is driven by the tested lead screw 3 and can move on the tested guide rail 2; ...

Embodiment 2

[0186]The control of the force exerting mechanism is basically the same as that of the scheme 1, and the industrial control computer is equipped with a PMAC card to control the stepping motor. The PMAC card is installed in the industrial control computer, the outside is connected with the interface board, and the interface board is connected with the servo motor through the servo driver. The PMAC card is connected with various sensors through the input and output interface board, and the control program is compiled in the computer. The control program calls the corresponding PMAC card motion control program to complete the drive of the servo motor and walk out of the corresponding trajectory. Combined with the specific situation of this test bench, the 12-axis PMAC control card combined with the servo interface board and the input and output interface board is used for system control. The hardware structure is as follows: Figure 31 As shown, other content adapts to change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com