Polyolefin film

A polyolefin, film-based technology, applied in the direction of hydrocarbon copolymer adhesives, film/sheet-like adhesives, adhesive types, etc., can solve the problem of difficult to cause film elongation or deformation, achieve inhibition The effect of excellent adhesion, processability, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

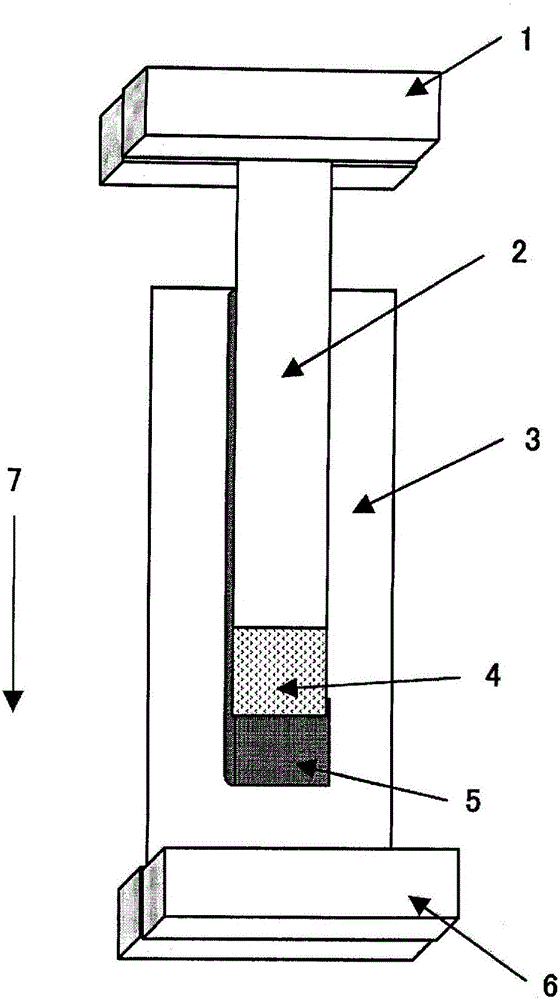

Image

Examples

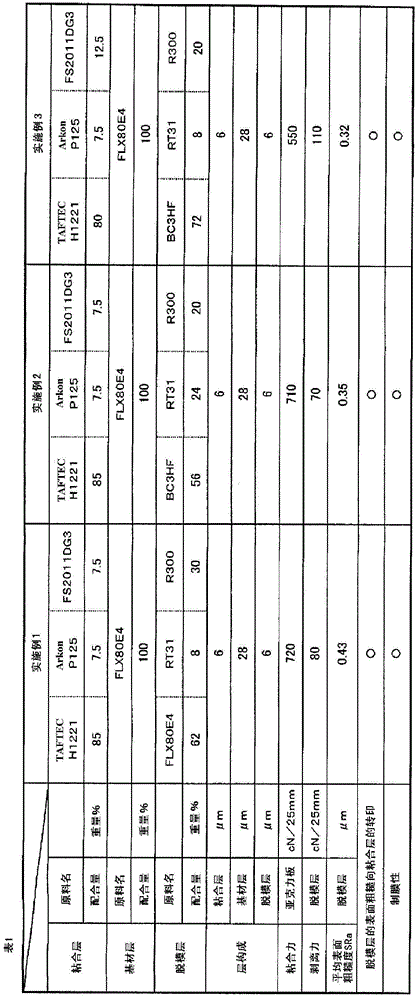

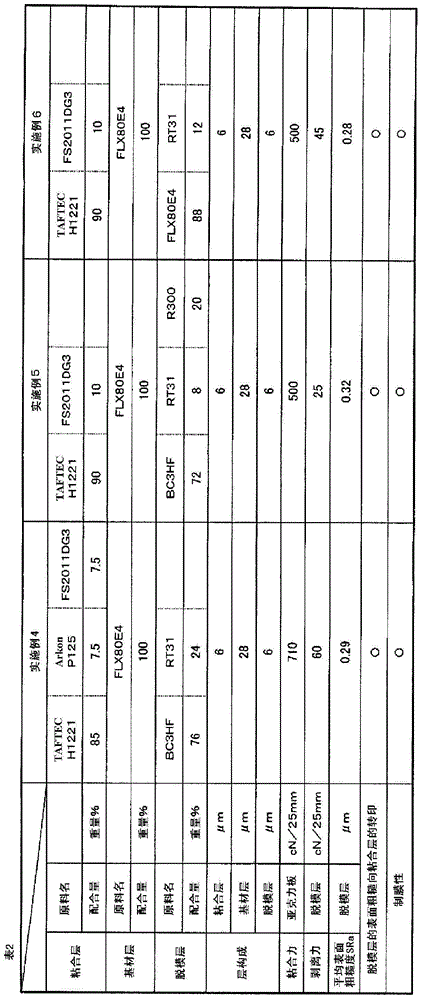

Embodiment 1

[0086] (Preparation of substrate layer)

[0087] 100 wt% of a homopolypropylene resin (manufactured by Sumitomo Chemical: FLX80E4, MFR: 7.5 g / 10 minutes) was melt-extruded at 240° C. with a 120 mmφ single-screw extruder to form a substrate layer.

[0088] (Preparation of adhesive layer)

[0089] Styrene-based elastomer (manufactured by Asahi Kasei Chemicals: TAFTEC (registered trademark) H1221, styrene copolymerization ratio: 12 wt%, MFR: 4.5 g / 10 minutes) 85 wt%, homopolypropylene resin (manufactured by Sumitomo Chemical: FS2011DG3, MFR: 2.5 g / 10 minutes) 7.5 wt% and petroleum resin (Arkon (registered trademark) P125) 7.5 wt% were melt-extruded at 220° C. with a 90 mmφ single-screw extruder to form an adhesive layer.

[0090] (production of release layer)

[0091] Homopolypropylene resin (manufactured by Sumitomo Chemical: FLX80E4, MFR: 7.5g / 10min) 62wt%, low-density polyethylene resin (manufactured by Ube: R300) 30wt% and polymethylpentene (manufactured by Mitsui Chemicals...

Embodiment 2

[0095] The pressure-sensitive adhesive layer and the base material layer were kept the same as in Example 1, and the release layer was changed to the following, and three types of three-layer unstretched films were obtained by the same manufacturing method as in Example 1.

[0096] (production of release layer)

[0097] Propylene-ethylene block copolymer (manufactured by Japan Polypropylene Corporation: BC3HF) 56wt%, low-density polyethylene resin (Ube Industries: R300) 20wt%, and polymethylpentene (Mitsui Chemicals: RT31) 24wt%, with 90mmφ A single-screw extruder was used for melt extrusion at 250° C. to form a release layer.

Embodiment 3

[0099] The substrate layer was kept the same as in Example 1, and the adhesive layer and the release layer were changed to the following, and three types of three-layer unstretched films were obtained by the same manufacturing method as in Example 1.

[0100] (Preparation of adhesive layer)

[0101] Styrenic elastomer (manufactured by Asahi Kasei Chemicals: TAFTEC (registered trademark) H1221, styrene copolymerization ratio: 12 wt%, MFR: 4.5 g / 10 minutes), petroleum resin (manufactured by Arakawa Chemical Industry: Arkon (registered trademark) P125) and homogeneous Polypropylene resin (manufactured by Sumitomo Chemical: FS2011DG3, MFR: 2.5g / 10min) was mixed at a ratio of 80 / 7.5 / 12.5wt%, and melt-extruded at 220°C with a 90mmφ single-screw extruder to produce adhesive layer.

[0102](production of release layer)

[0103] Propylene-ethylene block copolymer (manufactured by Japan Polypropylene Corporation: BC3HF) 72wt%, low-density polyethylene resin (Ube Industries: R300) 20wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com