Foamed polyphenyl ether/polystyrene blended alloy material and its preparation method

A polystyrene and polyphenylene ether technology, which is applied in the field of foamed polyphenylene ether/polystyrene (PPO/PS) blended gold materials and their preparation, can solve the problem of high technical equipment requirements and high process control requirements. Control, expensive equipment and other problems, to achieve the effect of outstanding physical and mechanical properties, excellent physical and mechanical properties, and easier process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

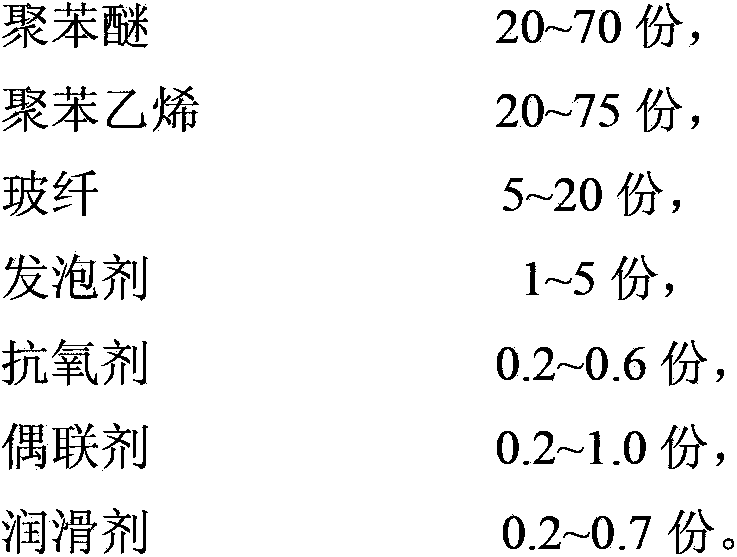

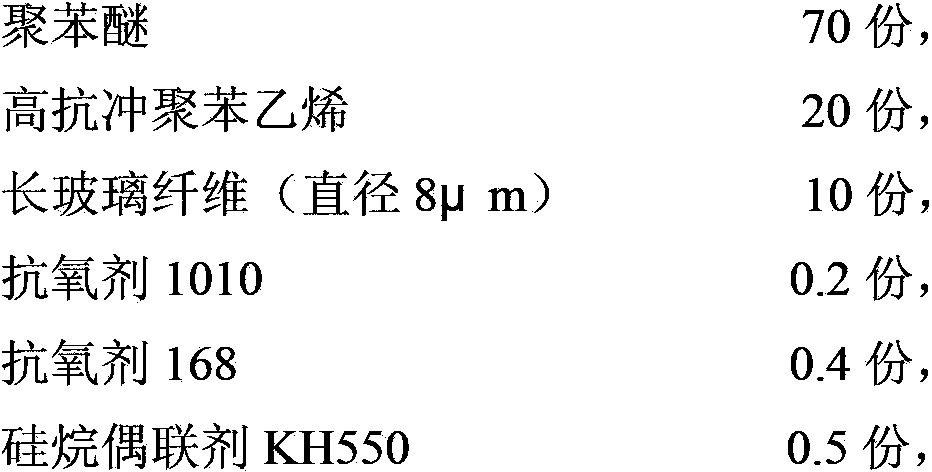

[0026] (1) Weigh the raw materials of each component according to the following parts by weight:

[0027]

[0028]

[0029] The above raw materials are mixed at a high speed by a high-speed mixer. The high-speed mixer speed is 1000rmp, the mixing temperature is 40°C, and mixed for 10 minutes; the mixed material is passed through a twin-screw extruder, and the temperature of each zone is controlled at 260-290°C. Diced;

[0030] (2) Mix the granulated particles with 5 parts of foaming agent azodicarbonamide at high speed with a high-speed mixer, the speed of the high-mixer is 1000rmp, the mixing temperature is 40°C, mix for 10min, and extrude through the extruder That is, foamed polyphenylene ether / polystyrene material, and its related properties are shown in Table 1.

Embodiment 2

[0032] (1) Weigh the raw materials of each component according to the following parts by weight:

[0033]

[0034] The above raw materials are mixed at a high speed by a high-speed mixer, the speed of the high-speed mixer is controlled at 800rmp, the mixing temperature is 80°C, and the mixture is mixed for 3 minutes; the mixed material is passed through a twin-screw extruder, and the temperature of each zone is controlled at 240-265°C , extruder strand pelletizing strand pelletizing;

[0035] (2) The granulated particles and 2 parts of foaming agent barium azodicarboxylate are mixed at high speed by a high-speed mixer. The high-speed mixer speed is 800rmp, the mixing temperature is 40°C, mixed for 10min, and extruded by an extruder That is, foamed polyphenylene ether / polystyrene material, and its related properties are shown in Table 1.

Embodiment 3

[0037] (1) Weigh the raw materials of each component according to the following parts by weight:

[0038]

[0039] The above raw materials are mixed at a high speed by a high-speed mixer. The speed of the high-speed mixer is 900rmp, and the mixing temperature is 60°C. After mixing for 6 minutes, the mixed material is passed through a twin-screw extruder. The temperature of each zone is controlled at 250-280°C. Straw dicing Strand dicing;

[0040] (2) The granulated particles and 1.8 parts of foaming agent N, N-dinitrosopentamethylenetetramine are mixed at high speed by a high-speed mixer. The high-speed mixer speed is 900rmp, and the mixing temperature is 40°C. After mixing for 10 minutes, the foamed polyphenylene ether / polystyrene material can be obtained by extruding through an extruder, and its related properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com