Disposable Bioreactor

A technology of bioreactor and reactor, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc. The effect of mass efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

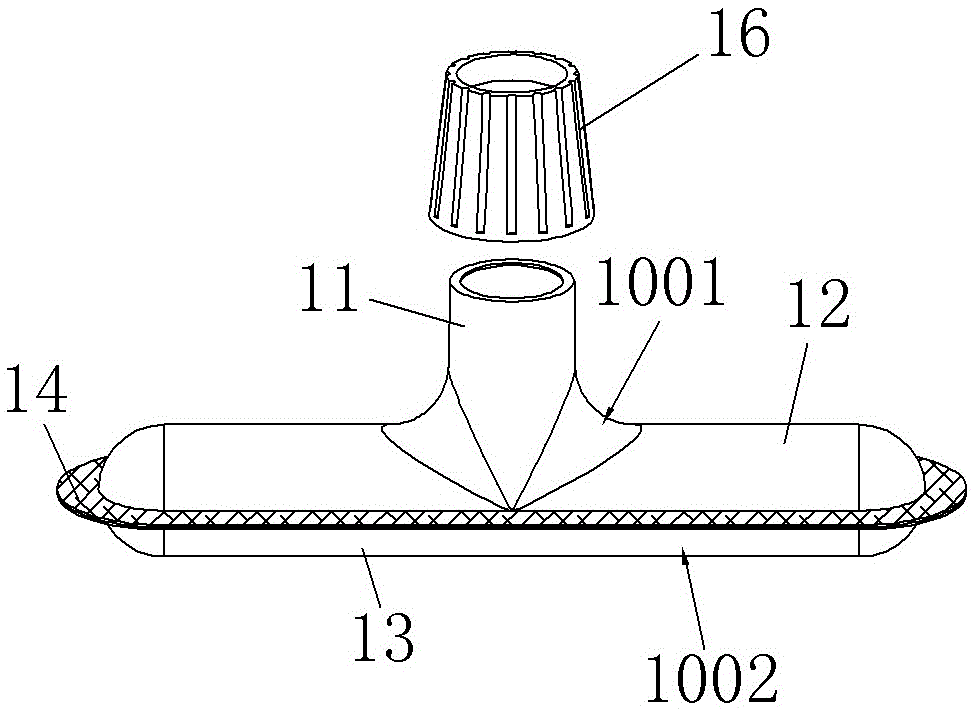

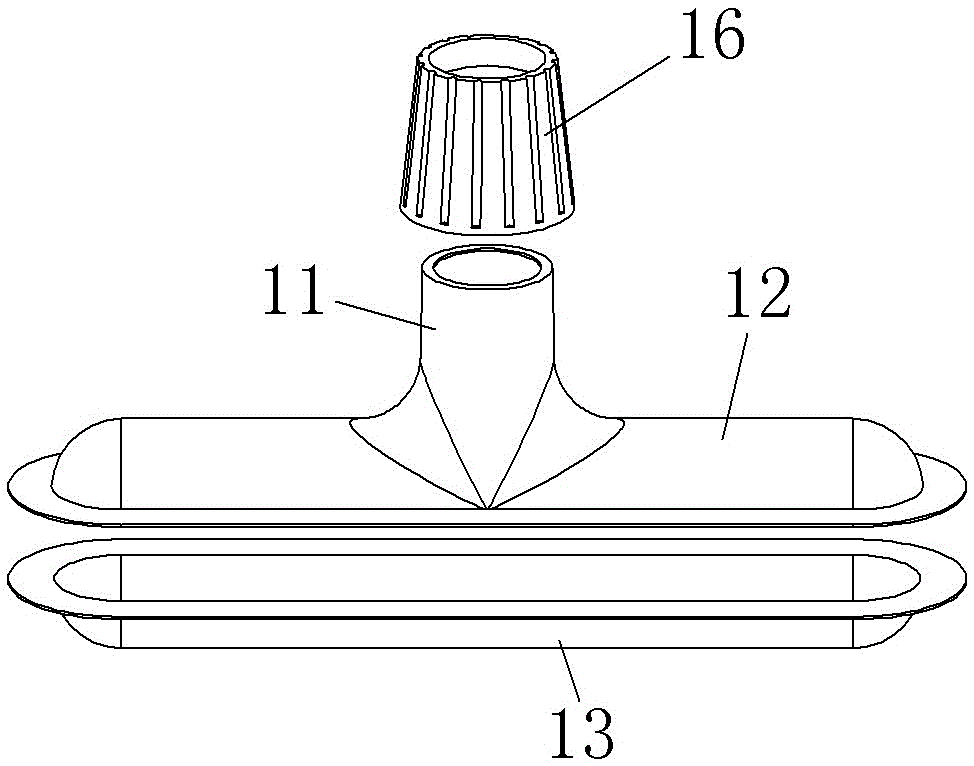

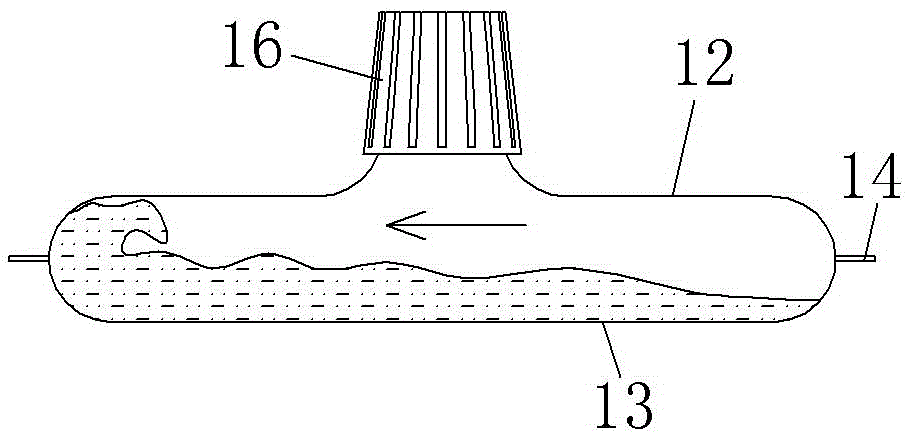

[0062] Example 1 of a disposable bioreactor, such as Figure 1-5 As shown, the disposable bioreactor includes a reactor cavity and a connecting pipe 11, and the reactor cavity is made of non-toxic and harmless plastic material, which can meet the requirement of one-time use, from figure 1 , 2 It can be seen from the figure that the reactor chamber is formed by the fusion of two chamber walls. The two chamber walls are arranged one above the other. The upper one is the upper chamber wall 12, the lower one is the lower chamber wall 13, and the upper one is the lower chamber wall 13. 1. The fusion of the lower cavity wall forms a joint edge 14, which can support and pull the reactor cavity through the joint edge 14 when needed; the connecting pipe 11 is located on the upper cavity wall 12 and is an integral structure with the upper cavity wall 12 . In this embodiment, the upper and lower cavity walls are all solid support cavity walls, that is, the cavity walls that can maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com