A kind of anode applied to alkaline zinc-nickel alloy electroplating

A zinc-nickel alloy and anode technology, which is applied in the direction of electrodes, can solve the problems of complex electroplating process management, etc., and achieve the effects of improving the difficulty of electroplating process management, low use cost, and simple anode structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

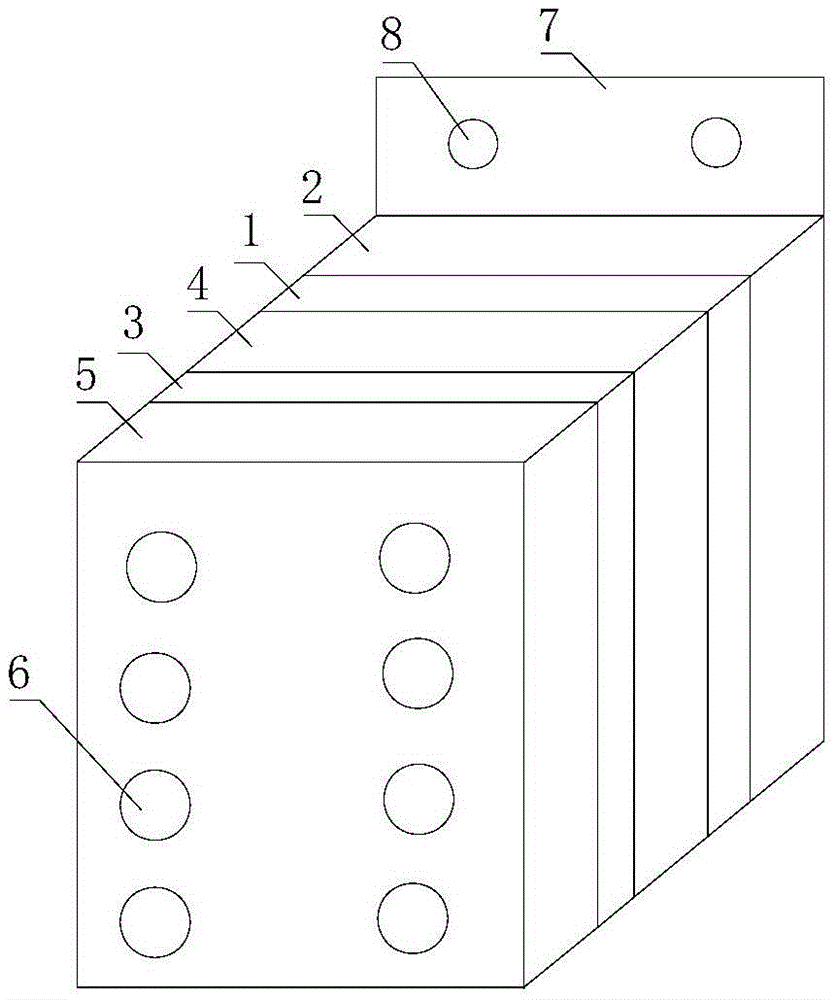

[0015] figure 1 Shown is the first embodiment of the present invention applied to the anode of alkaline zinc-nickel alloy electroplating. The anode applied to the alkaline zinc-nickel alloy electroplating includes a plate-shaped zinc material 1, and can increase and decrease the zinc material 1 contacting the electroplating solution when the anode applied to the alkaline zinc-nickel alloy electroplating is placed in the electroplating solution Area barriers. The barrier device is made of a material with an electrode potential higher than that of zinc. In this embodiment, all structures of the barrier device are made of carbon steel.

[0016] In the electroplating process, since the electrode potential of the material of the barrier device, that is, carbon steel, is higher than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com