Water-source heat pump water-saving high-efficiency recharge system

A technology of water source heat pumps and water source heat pump units, applied in heat pumps, heating devices, geothermal energy power generation, etc., can solve problems such as increasing water intake, increasing initial investment costs, increasing equipment wear, etc., to improve operating efficiency, control and adjust Convenience and the effect of preventing well accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific embodiment of the present utility model will be further described.

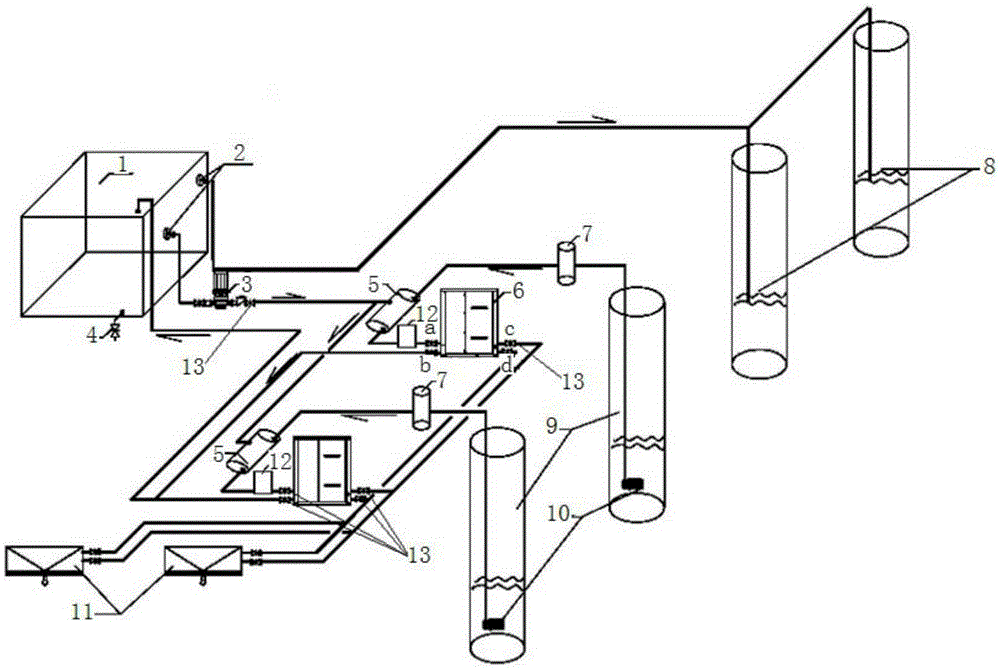

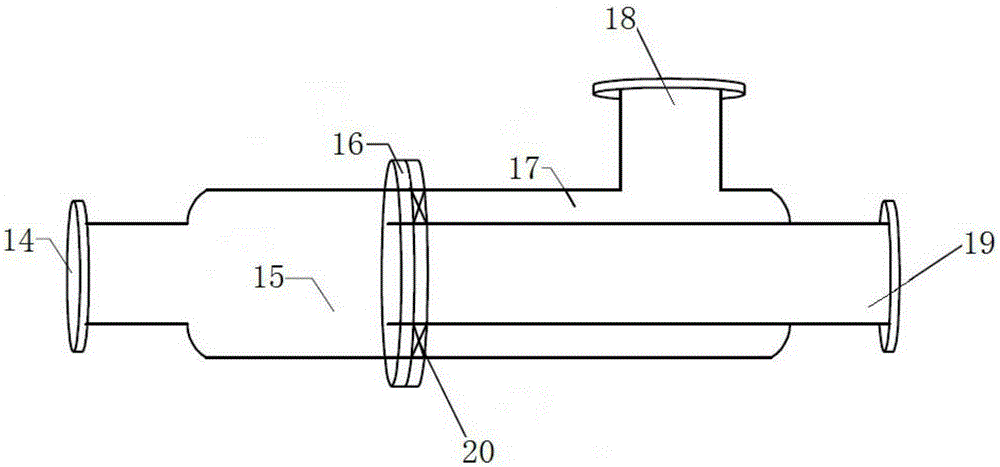

[0015] The utility model is realized in this way, which includes: a water separation treatment device 1, a filter 2, a water source heat pump unit 6, a swirl sand remover 7, a return well 8, a water well 9, a submersible pump 10, and a fan coil unit 11 And throttle valve 13, its structure is: it also includes heat pump water supply pump 3 and water mixer 5, one end of said heat pump water supply pump 3 is connected to water mixer 5 through pipeline, and the other end is connected with water separation treatment through pipeline The filter 2 on the upper part of the device 1 is connected, and the water separation treatment device 1 and the return well 8 are connected through pipelines; the water mixer 5, the cyclone sand remover 7 and the submersible pump 10 located in the pumping well 9 are sequentially connected in series. On the same pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com