Heat exchanger provided with micro micro-channel metal circular pipes for air cooled air conditioner

A micro-channel and air-conditioner technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as failure to achieve micro-scale effects, reduce packaging and transportation costs, increase wind resistance, and slow down wind speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

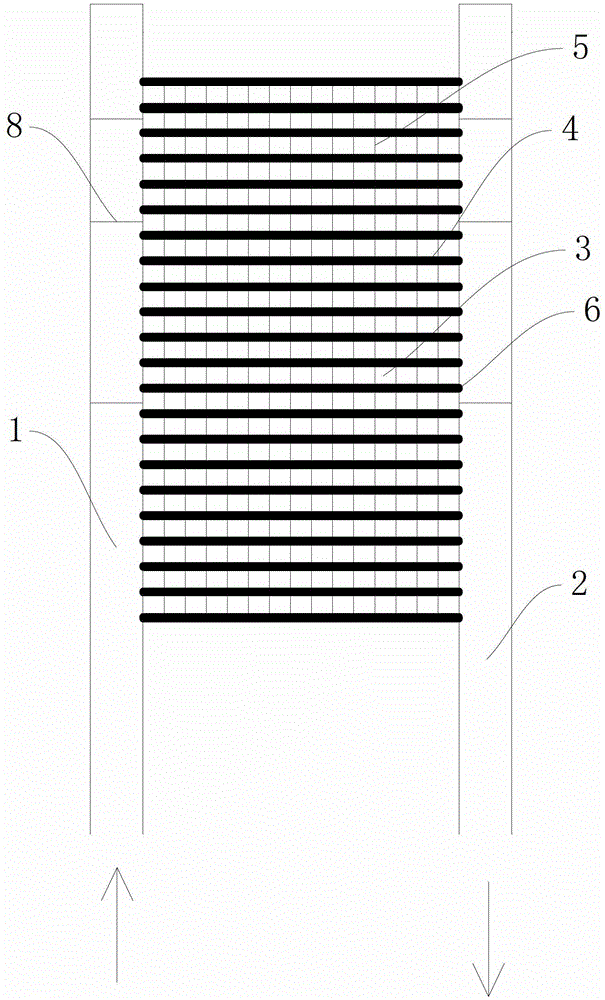

[0014] Such as figure 1 As shown, the heat exchanger for the miniature microchannel metal circular tube of the air-cooled air conditioner described in this embodiment includes an inlet pipe 1, an outlet pipe 2 and a heat exchange mechanism 3, and the inlet pipe 1 and the outlet pipe 2 The heat exchange mechanism 3 is connected by the heat exchange mechanism 3. The heat exchange mechanism 3 is made of a micro-microchannel metal circular tube 4 and a metal wire 5. The outlet pipe 2 is connected with an inner diameter of 0.1 mm, and the metal wire 5 is a weft thread, and is welded with the miniature microchannel metal round pipe 4 . The inlet pipe 1 and the outlet pipe 2 adopt a metal round pipe structure, and holes 6 are formed on the pipe wall, and the micro-microchannel metal round pipe 4 is welded and fixed to the inlet pipe 1 and the outlet pipe 2 through the opening 6 . An anti-corrosion and leak-proof layer is also provided on the surface of the heat exchange mechanism 3,...

Embodiment 2

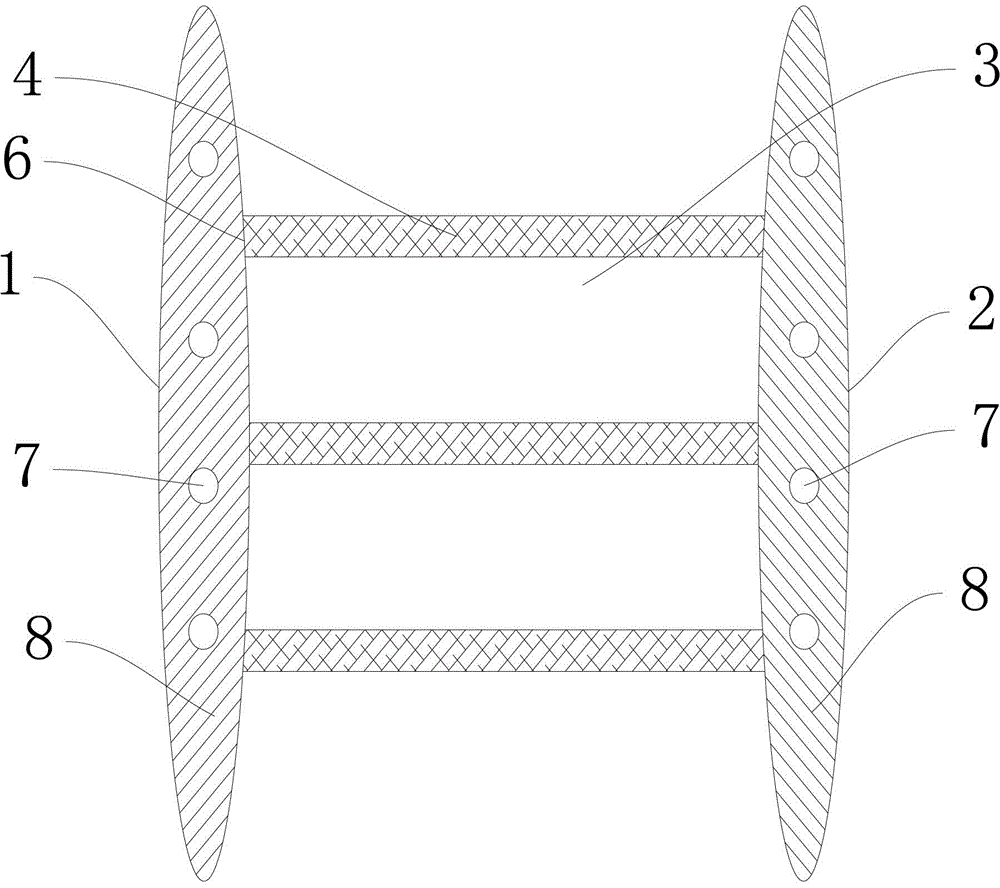

[0016] Such as figure 2 As shown, the heat exchanger for the miniature microchannel metal round tube 4 of the air-cooled air conditioner described in this embodiment, the inlet tube 1 and the outlet tube 2 are flat tube structures, and the miniature microchannel metal round tube The inner diameter of the tube 4 is 0.4 mm, and the rest of the metal wires 5 form a mesh heat exchange mechanism 3 . Between the inlet pipe 1 and the outlet pipe 2, three layers of stacked heat exchange mechanisms 3 are arranged to form a parallel structure. The inlet pipe 1 and the outlet pipe 2 are also provided with an isolation plate 8 through slotting, and the isolation plate 8 is provided with a drainage hole 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com