Power tower three-dimensional solid model generating method

A three-dimensional entity and model generation technology, which is applied in 3D modeling, electrical digital data processing, image data processing and other directions, can solve the problems of unrealistic, time-consuming, high cost, save time and cost, improve design accuracy, reduce the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

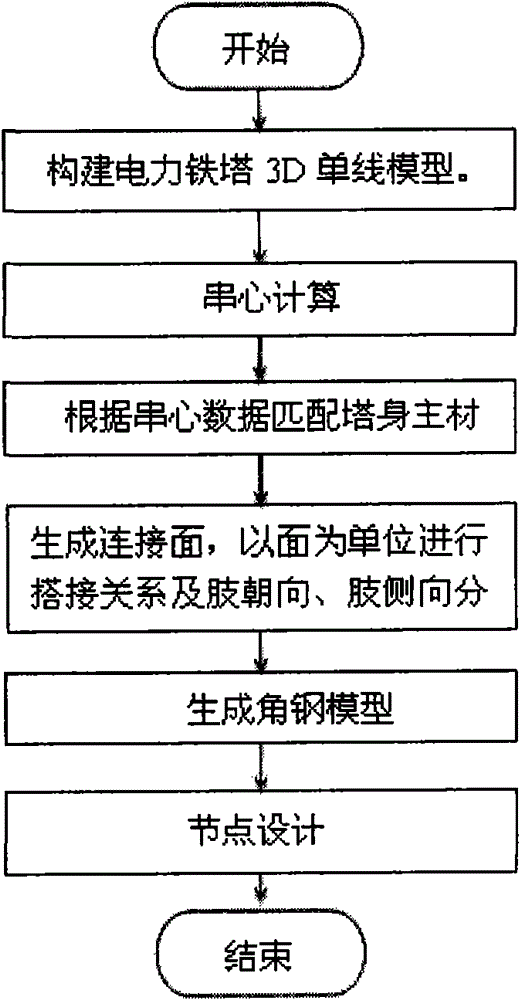

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

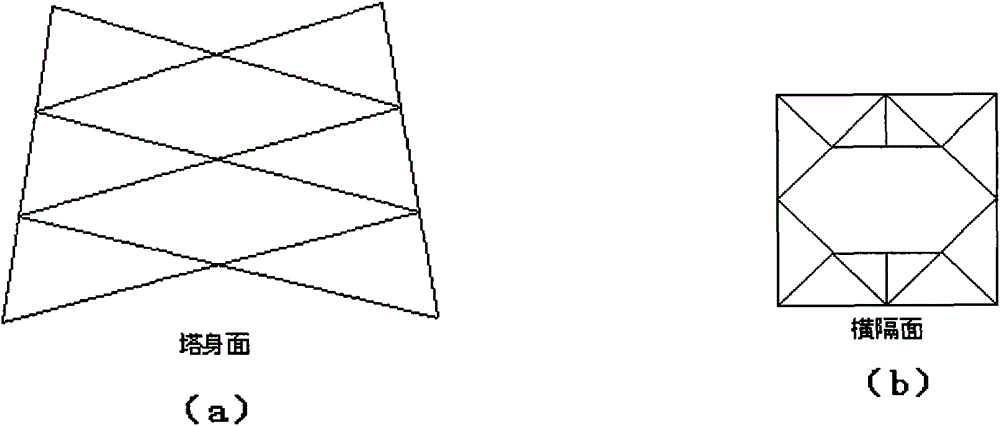

[0021] Power towers are usually made of angle steel and steel plate components, and are combined with bolts, and a small amount of welding can also be used locally. The power tower is divided into tower foot, tower body, tower head, cross arm, cross partition and other parts. According to the connection relationship, the rods in each of the above parts can be subdivided into main materials, oblique materials and auxiliary materials. .

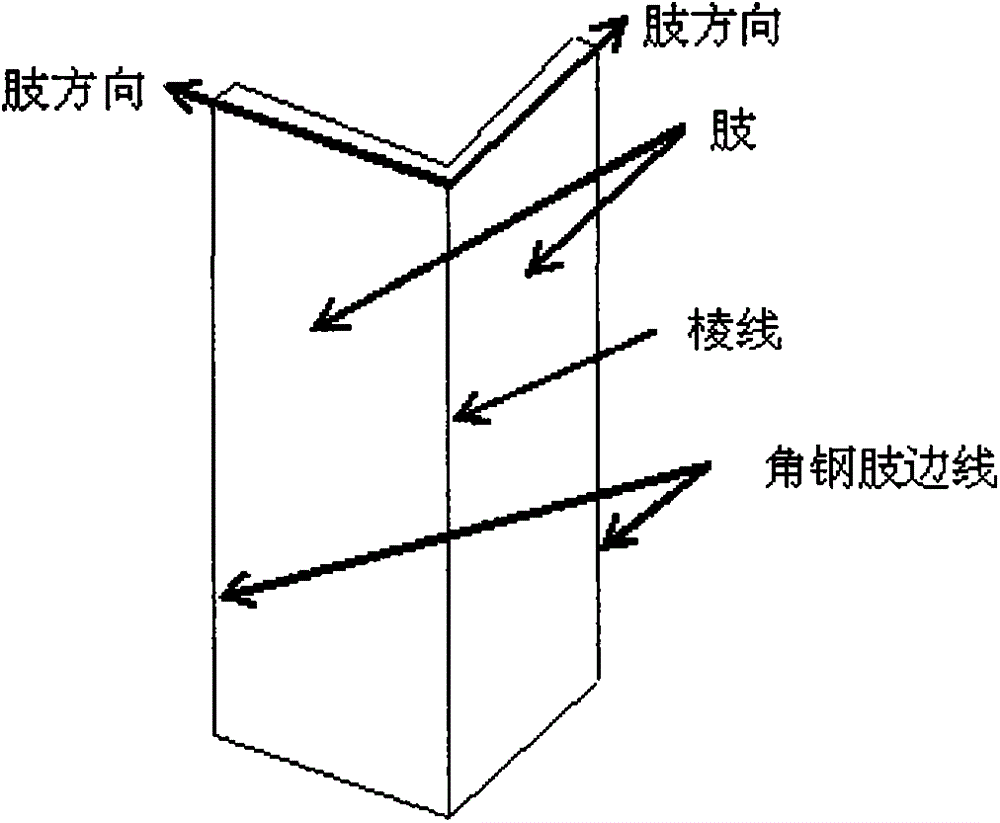

[0022] Such as figure 1 As shown, an angle steel model in three-dimensional space is determined by the edge point of the angle steel, the direction of the two limbs and the specification of the angle steel (leg width, limb thickness). The leg direction of the angle steel is the direction from the end point of the edge line of the angle steel to the end point of the edge line of the leg, and the leg direction is perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com