Oil-resistant water-proof corrosion-resistant double-shielded control cable for coal mine

A control cable, anti-corrosion technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem that the cable is difficult to meet the requirements of use, and achieve the effect of good electrical conductivity, good shielding effect, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

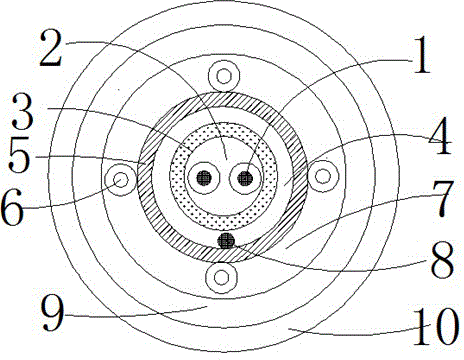

[0010] Such as figure 1 As shown, the present invention is realized by adopting the following technical solutions: an oil-resistant, waterproof, and anti-corrosion double-shielded control cable for coal mines, which includes a main core 1, a control core 6, a tape layer 2, an insulating layer 4, and a shielding layer 5 , a waterproof layer 9 and a protective cover 10, an inner shielding layer 3 is provided between the tape layer 2 and the insulating layer 4, and the inner shielding layer 3 is braided by nickel-plated copper-aluminum alloy wire wrapped around silicon rubber The heat insulation layer 7 is wrapped between the shielding layer 5 and the waterproof layer 9, the heat insulation layer 7 wraps the grounding core 8 and the control core 6 inside, the main core 1, the control core 6 , ground wire core 8 are respectively two, four, one, and described protective sheath 10 is the steel wire outsourcing nitrile sheath that adds anticorrosion agent, oil resistance agent.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com