Laser drilling plate machining method adopting secondary outer-layer core material for reducing copper

A technology of laser drilling and processing methods, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., to achieve the effect of extensive promotion, improve product yield, and solve the problem of laser hole breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention relates to a laser drilling board processing method using sub-outer layer core material to reduce copper, which includes sub-outer layer pattern making, lamination and laser drilling.

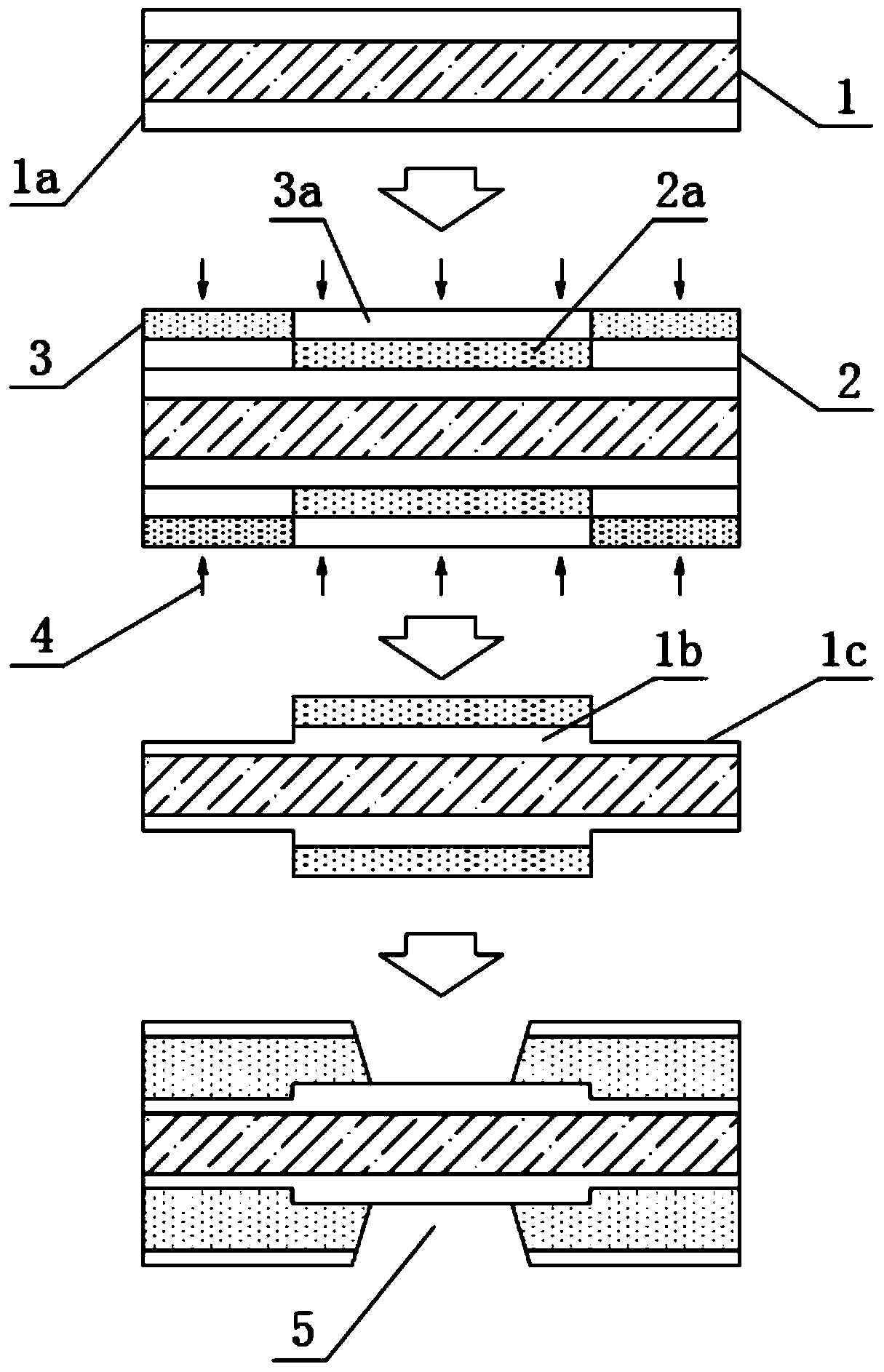

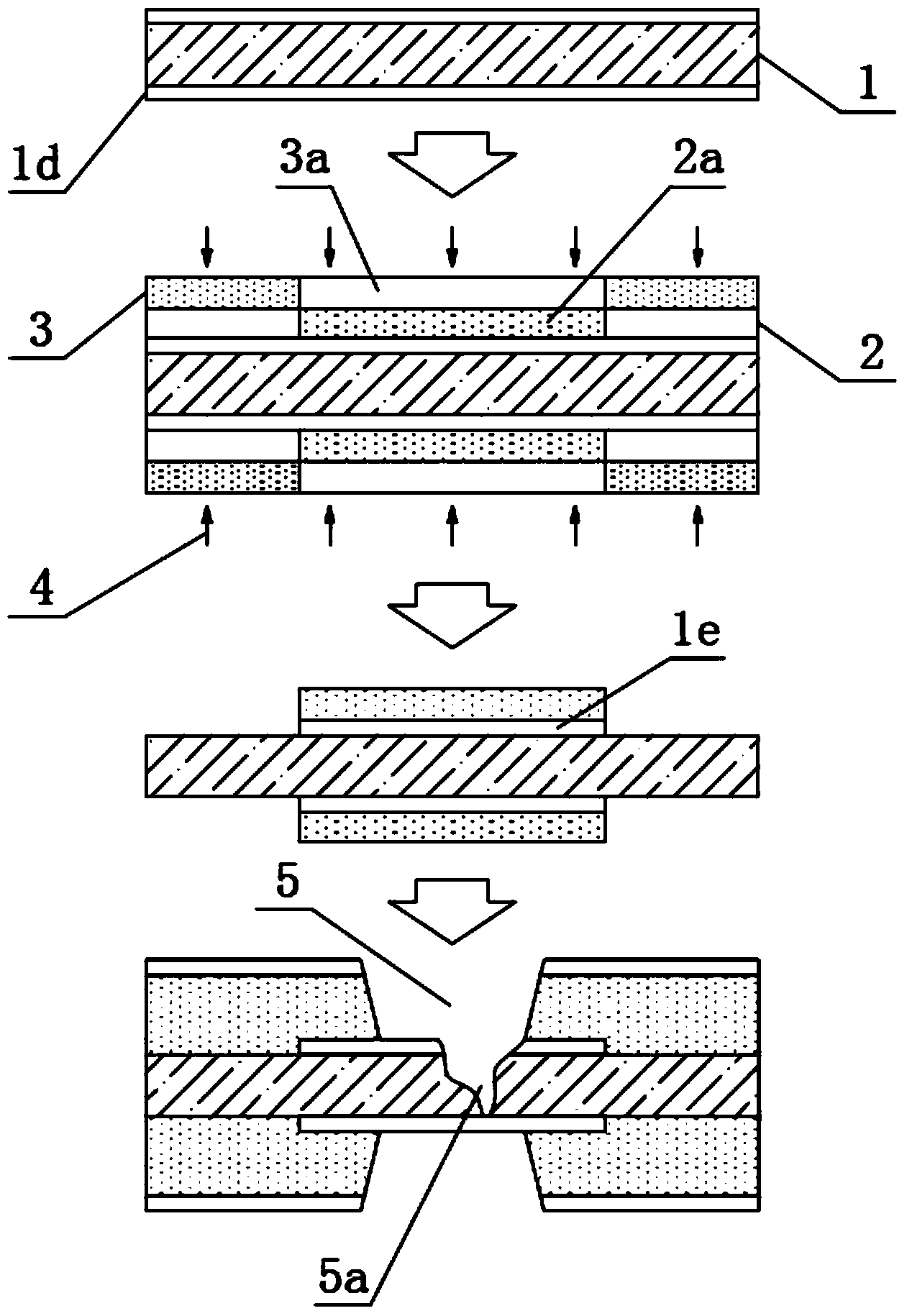

[0024] Such as figure 1 As shown, take the example of reducing the base copper thickness of the sub-outer core material from 0.5OZ to 0.33OZ:

[0025] The sub-outer core material 1 is made of 0.5OZ-based copper 1a, and a dry film 2 is pasted on it, and the film 3 is covered. Under the irradiation of ultraviolet light 4, the light-receiving dry film 2a under the empty area 3a without chemical film is developed. Retained on the sub-outer core material 1, through the action of copper reduction, the exposed 0.5OZ base copper 1a is thinned by about 3-4um to become a 0.5OZ base copper thinning layer 1c, while the light-receiving dry film 2a protects The 0.5OZ base copper 1a becomes the 0.5OZ receiving plate 1b; after subsequent lamination, skylight layer fabrication, and laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com