Partition with heat-resistant insulation

A heat-resistant insulation and separator technology, used in hybrid capacitor separators, layered products, cellulose plastic material layered products, etc., can solve problems such as the increase in the amount of adsorbed water and the impact of battery cycle characteristics and output characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

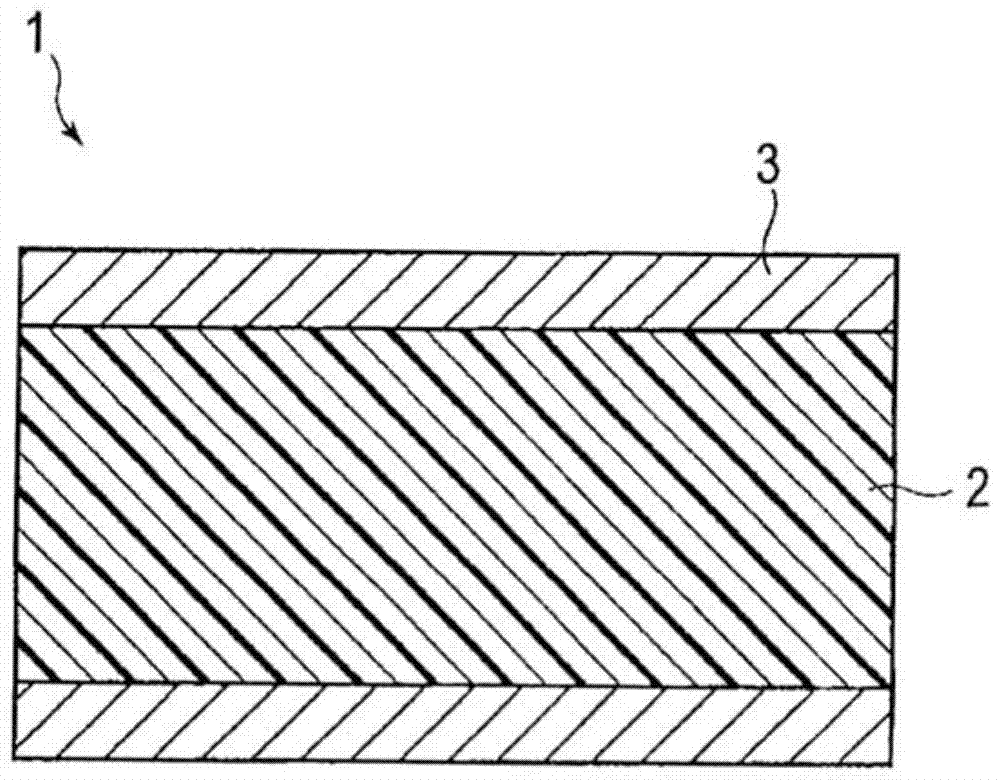

[0118] Alumina particles (BET specific surface area: 5m 2 / g, average particle size 2 μm) 95 parts by mass and carboxymethyl cellulose as a binder (moisture content per unit binder mass: 9.12 mass%, manufactured by Nippon Paper Chemical Co., Ltd., Sunrose (registered trademark) MAC series) 5 parts by mass were uniformly dispersed in water to prepare an aqueous solution. This aqueous solution was applied to both surfaces of a polyethylene (PE) microporous membrane (film thickness: 18 μm, porosity: 55%) using a gravure coater. Then, water was removed by drying at 60° C., and a separator with a heat-resistant insulating layer (heat-resistant insulating layer) of a multilayer porous film with a total film thickness of 25 μm was formed on both sides of the porous membrane with heat-resistant insulating layers of 3.5 μm each. Gram weight 10g / m 2 ).

[0119] In addition, the BET specific surface area of an inorganic particle is the value measured by the following measuring method...

Embodiment 2

[0129] A separator with a heat-resistant insulating layer was produced as in Example 1, except that a BET specific surface area was used: 7m 2 / g of alumina particles.

Embodiment 3

[0131] A separator with a heat-resistant insulating layer was produced as in Example 1, except that a BET specific surface area was used: 15m 2 / g of alumina particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com