Catalyst of basic ionic liquid immobilized on metal-organic frameworks and preparation method thereof

A metal-organic framework and liquid catalyst technology, which is applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., to achieve the effects of simple preparation methods, easy separation of products, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

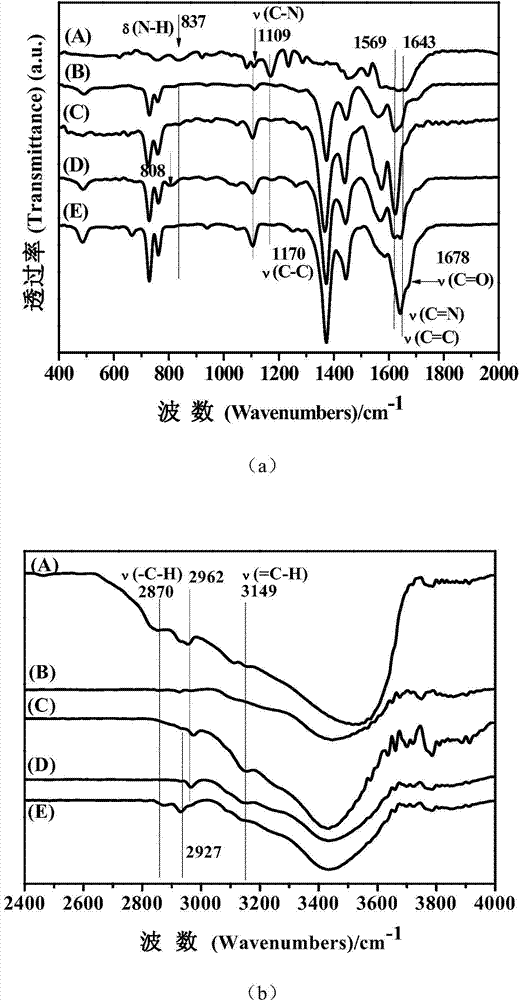

Method used

Image

Examples

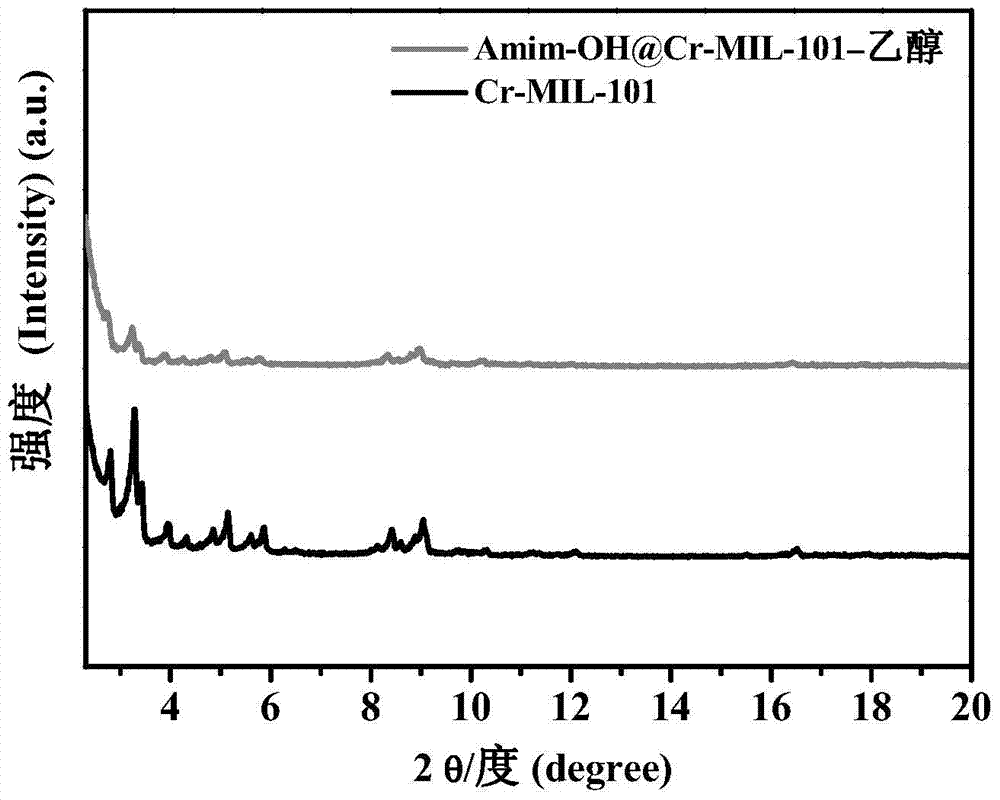

Embodiment 1

[0043] The preparation of I.Cr-MIL-101: join 2.8g terephthalic acid into 80ml deionized water, stir evenly on magnetic stirrer, add 6.32gCr (NO 3 ) 3 .9H 2 O, 800μl HF, stirred for 2h, and put the resulting mixture into the reaction kettle. Put the reaction kettle into an oven, set the temperature at 220°C, and crystallize for 8 hours. After the reaction was completed, the reactor was taken out, cooled to 150° C. with water, and then naturally cooled to room temperature, and the color of the solid in the obtained product was emerald green. Then filter with suction, first filter with a large-pore sand core funnel (G2) to remove residual terephthalic acid, and then filter with a small-pore sand core funnel (G4) to obtain an emerald green solid product. Put the solid product and 95% ethanol aqueous solution in a reaction kettle, purify at 80°C for 24 hours, suction filter while it is hot and wash the solid product with 50°C hot ethanol; put the solid product obtained after the...

Embodiment 2

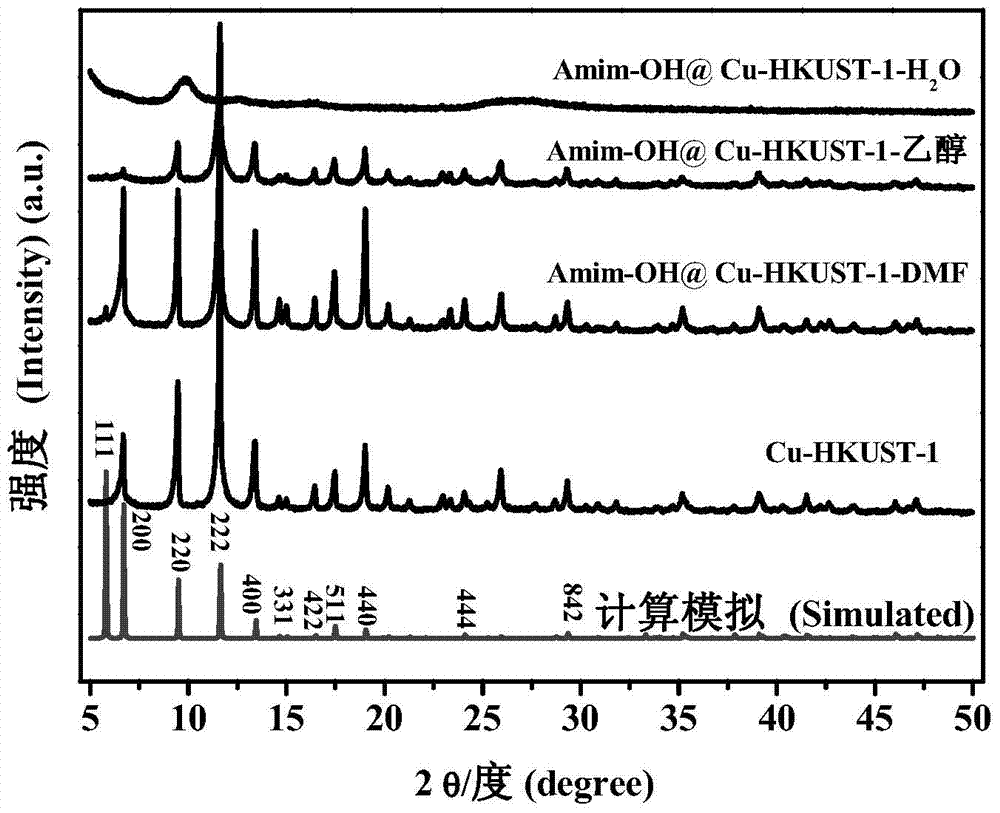

[0047] The preparation of I.Cu-HKUST-1: take by weighing 7.97g (33mmol) Cu(NO 3 ) 2 ·3H 2 O, dissolved in 10ml of deionized water, then weighed 3.85g (18.3mmol) trimesic acid (BTC) and dissolved in 110ml of ethanol. Then they were stirred until completely dissolved, and the two solutions were mixed and stirred for 30 minutes. Then it was transferred to a reactor and reacted at 120°C for 12h. Then cool, filter with suction, wash with deionized water (20ml x3) and absolute ethanol (10ml x3) respectively, and then dry in an oven at 80°C to obtain a blue Cu-HKUST-1 metal-organic framework material.

[0048] II. Preparation of amino-functionalized imidazole-based basic ionic liquid Amim-OH: same as in Example 1.

[0049] III. Catalyst preparation: 0.5 g of Cu-HKUST-1 obtained in step I was placed in a vacuum drying oven and dried at 150° C. for 12 hours. 0.3 g of the amino-functionalized imidazolium-based basic ionic liquid Amim-OH obtained in step II was dissolved in 25 mL of...

Embodiment 3

[0051] The preparation of I.Cu-HKUST-1: with embodiment 2.

[0052] II. Preparation of amino-functionalized imidazole-based basic ionic liquid Amim-OH: same as in Example 1.

[0053] III. Catalyst preparation: 0.5 g of Cu-HKUST-1 obtained in step I was placed in a vacuum drying oven and dried at 150° C. for 12 hours. 0.3 g of the amino-functionalized imidazolium-based basic ionic liquid Amim-OH obtained in step II was dissolved in 25 mL of DMF. Disperse the vacuum-dried Cu-HKUST-1 material into the DMF solution of Amim-OH, and stir at room temperature for 24h to obtain a suspension. The suspension obtained above was vacuum filtered, washed with DMF and ethanol (3×10 mL), and dried in vacuum at 80° C. for 12 h to obtain the catalyst Amim-OHCu-HKUST-1-DMF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com