Preparation method for substrate for planting edible fungus

A technology of edible fungus and matrix, applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems of prolonging the fruiting time, decreasing the output of edible fungi, reducing the biotransformation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

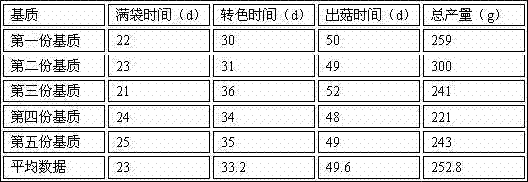

Embodiment 1

[0036] A method for preparing a substrate for cultivating edible fungi, characterized in that it comprises the following steps:

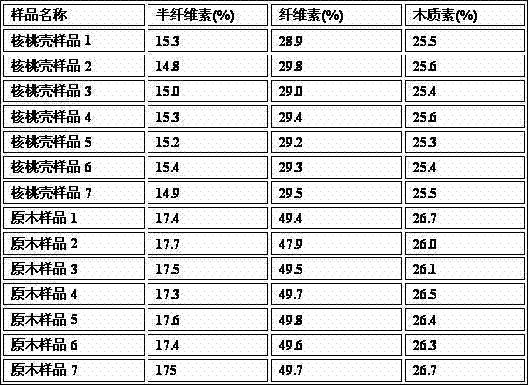

[0037] (1) Treat walnut shells, crush the walnut shells into particles with a diameter of less than 10mm, soak the walnut shells in plant ash water for 24 hours, the quality of the plant ash water is twice the mass of the walnut shells, and wait for use after treatment;

[0038] (2) Treat and roast mulberry branches, crush pine wood chips into particles with a diameter of less than 10 mm, crush mulberry branches, flue-cured tobacco rods, pine wood particle tobacco rods and pine wood chips, and crush mulberry branches and flue-cured tobacco rods into particles with a diameter of less than 15 mm Dethinified terpene, degreasing treatment, stand-by;

[0039] (3) In parts by weight, mix 30 parts of walnut shells, 10 parts of mulberry branches, 10 parts of pine sawdust, and 10 parts of bran, add 0.5 parts of glucose and 1 part of gypsum and mix.

Embodiment 2

[0041] A method for preparing a substrate for cultivating edible fungi, characterized in that it comprises the following steps:

[0042] (1) Treat the walnut shells, crush the walnut shells into particles with a diameter of less than 10mm, soak the walnut shells in plant ash water for 36 hours, the quality of the plant ash water is 2-6 times the mass of the walnut shells, and wait for use after treatment;

[0043](2) Processing and roasting mulberry branches, crushing pine sawdust into particles with a diameter of less than 10mm, crushing mulberry branches, flue-cured tobacco rods, pine pellet tobacco rods and pine wood chips, and crushing mulberry branches and flue-cured tobacco rods into particles with a diameter of less than 15mm Dethinified terpene, degreasing treatment, stand-by;

[0044] (3) In parts by weight, mix 45 parts of walnut shells, 15 parts of mulberry branches, 15 parts of pine sawdust, and 15 parts of chaff, add 0.8 parts of glucose and 1 part of gypsum for m...

Embodiment 3

[0046] A method for preparing a substrate for cultivating edible fungi, characterized in that it comprises the following steps:

[0047] (1) Treat the walnut shells, crush the walnut shells into particles with a diameter of less than 10mm, soak the walnut shells in the plant ash water for 48 hours, the mass of the plant ash water is 6 times the mass of the walnut shells, and wait for use after treatment;

[0048] (2) Processing and roasting mulberry branches, crushing pine sawdust into particles with a diameter of less than 10mm, crushing mulberry branches, flue-cured tobacco rods, pine pellet tobacco rods and pine wood chips, and crushing mulberry branches and flue-cured tobacco rods into particles with a diameter of less than 15mm Dethinified terpene, degreasing treatment, stand-by;

[0049] (3) In parts by weight, mix 60 parts of walnut shells, 20 parts of mulberry branches, 20 parts of pine sawdust, and 20 parts of bran, add 1 part of glucose and 1 part of gypsum and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com