A kind of culture medium for producing straw mushroom and its preparation method

A culture medium and a technology for producing seeds, which are applied in the field of straw mushroom production seed medium and its preparation, can solve the problems of increased environmental pollution, easy aging of original seeds, short storage period, etc., and achieve high mushroom conversion rate and long storage period , to avoid the effect of environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

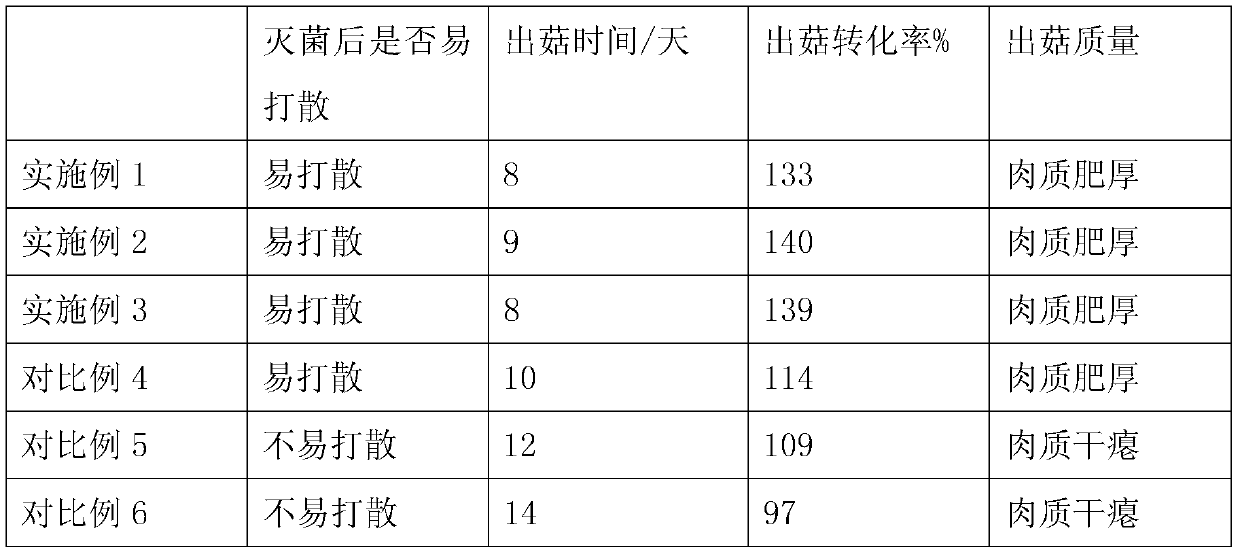

Examples

preparation example Construction

[0021] The present invention also provides a kind of preparation method of above-mentioned straw mushroom production medium, comprising the following steps:

[0022] a. Take the raw materials by weight, crush the cow dung, and crush the corncobs into particles with a particle diameter of ≤5mm, and set aside;

[0023] b. Mix corncobs, cow dung, cottonseed husks, bran, soybean meal and lactic acid, add water until the water content is 50-70%, seal and ferment for 6-7 days, turn over once every 2 days;

[0024] c. After step b is completed, add quicklime and sodium bicarbonate while stirring, then add cellulase and hemicellulase, adjust the water content of the medium to 60-70%, put it into a strain bottle, sterilize at high temperature, and prepare Straw mushroom culture medium was obtained.

[0025] Wherein, in the preparation method of the above-mentioned straw mushroom production medium, the fermentation temperature in step b is 15-18°C.

[0026] Wherein, in the preparation...

Embodiment 1

[0035] Preparation of Seed Medium 1 for Volvariella volvacea production.

[0036] Straw mushroom medium raw materials: by weight, 85 parts of corncobs, 10 parts of cow dung, 15 parts of cottonseed hulls, 20 parts of bran, 20 parts of soybean meal, 10 parts of lactic acid, 5 parts of quicklime, 5 parts of sodium bicarbonate, 0.1 part of cellulase, 0.1 part of hemicellulase.

[0037] The culture medium 1 for the production of straw mushrooms was prepared according to the following method.

[0038] Include the following steps:

[0039] a. Take the raw materials by weight, crush the cow dung, and crush the corncobs into particles with a particle diameter of ≤5mm, and set aside;

[0040] b. Mix corncobs, cow dung, cottonseed husks, bran, soybean meal and lactic acid, add water until the water content is 50%, seal and ferment for 6 days at a fermentation temperature of 15°C, turn over once every 2 days;

[0041] c. After step b is completed, add quicklime and sodium bicarbonate w...

Embodiment 2

[0043] Preparation of culture medium 2 for the production of straw mushrooms.

[0044] Straw mushroom medium 2 raw materials: by weight, 95 parts of corncobs, 20 parts of cow dung, 25 parts of cottonseed hulls, 15 parts of bran, 15 parts of soybean meal, 20 parts of lactic acid, 10 parts of quicklime, 10 parts of sodium bicarbonate , 2 parts of cellulase, 2 parts of hemicellulase.

[0045] The culture medium 2 for the production of straw mushrooms was prepared according to the following method.

[0046] Include the following steps:

[0047] a. Take the raw materials by weight, crush the cow dung, and crush the corncobs into particles with a particle diameter of ≤5mm, and set aside;

[0048] b. Mix corncobs, cow dung, cottonseed husks, bran, soybean meal and lactic acid, add water until the water content is 70%, seal and ferment for 7 days at a fermentation temperature of 18°C, turn over once every 2 days;

[0049] c. After step b is completed, add quicklime and sodium bicarbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com