A desorbent and its evaluation method

A technology of desorption and active agent, applied in the field of desorption agent and its evaluation, can solve the problems of unsatisfactory flowback effect, insufficient evaluation of adsorption capacity, large amount of addition, etc., achieve scientific and reasonable experimental method, reduce capital investment, change The effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

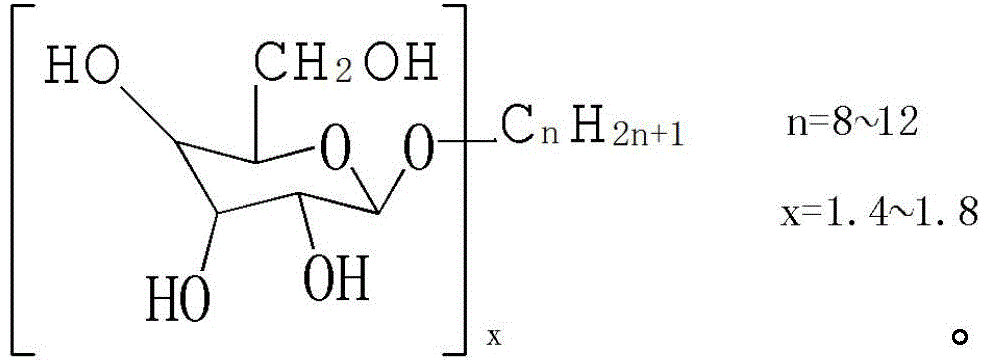

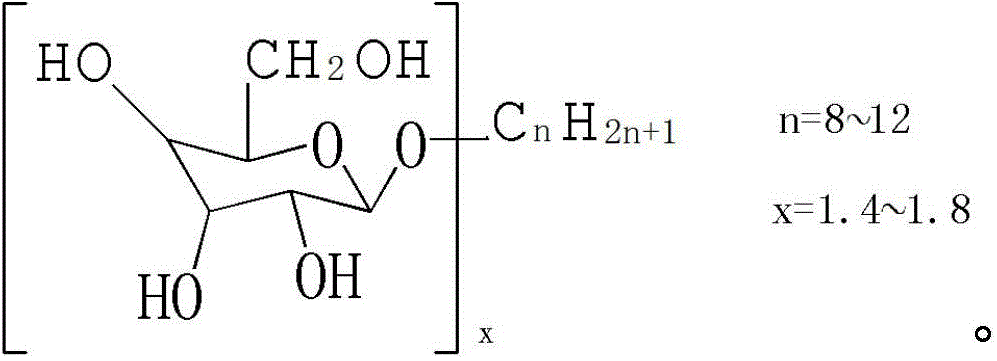

Method used

Image

Examples

Embodiment 1

[0051] Polyoxyethylene sorbitan monolaurate 20%, C 12 Fatty alcohol polyoxyethylene (10) ether 20%, alkyl polyglycoside 10%, ethylene glycol butyl ether 10%, isopropanol 5%, distilled water 35% stir at 30 ℃, mix and discharge; The adsorbent is prepared with a desorbent aqueous solution with a content of 0.1%.

[0052] Experimental results:

[0053]The surface tension of above-mentioned 0.1% desorbent aqueous solution is 29.6mN / m,

[0054] Desorption efficiency V 1 was 39.6%,

[0055] Desorption efficiency improvement rate F 1 was 13.8%.

Embodiment 2

[0057] Polyoxyethylene sorbitan monostearate 10%, C 12 Fatty alcohol polyoxyethylene (20) ether 20%, alkyl polyglycoside 10%, ethylene glycol butyl ether 10%, isopropanol 5%, distilled water 45% stir at 30 ℃, mix and discharge; The adsorbent is prepared with a desorbent aqueous solution with a content of 0.1%.

[0058] Experimental results:

[0059] The surface tension of the above-mentioned 0.1% desorbent aqueous solution is 30.3mN / m,

[0060] Desorption efficiency V 2 was 38.4%,

[0061] Desorption efficiency improvement rate F 2 was 12.6%.

Embodiment 3

[0063] Polyoxyethylene sorbitan monostearate 20%, C 12 Fatty alcohol polyoxyethylene (20) ether 15%, alkyl polyglycoside 5%, ethylene glycol butyl ether 10%, isopropanol 5%, non-ionic fluorocarbon surfactant 5%, distilled water 40% at 30°C Stir, mix evenly and discharge; configure a desorbent aqueous solution with a content of 0.1% according to the above desorbent.

[0064] Experimental results:

[0065] The surface tension of the above-mentioned 0.1% desorbent aqueous solution is 27.2mN / m,

[0066] Desorption efficiency V 3 was 40.1%,

[0067] Desorption efficiency improvement rate F 3 was 14.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com