Preparation method of high silicon-aluminum-carbon nano-tube intermediate alloy

A carbon nanotube and intermediate alloy technology, applied in the field of metal material preparation, can solve problems such as stress concentration, affecting the mechanical properties of composite materials, and destroying the integrity of carbon nanotubes, so as to facilitate dispersion, facilitate industrial production, and improve wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

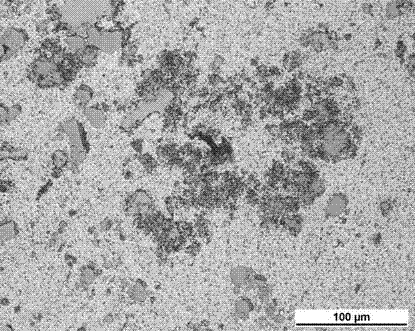

Image

Examples

Embodiment 1

[0014] Al-15Si alloy powder and CNTs are used as raw materials (CNTs account for 6wt.% of the total weight of the raw materials), and then the prepared raw materials are added to the ball mill for vacuum ball milling to obtain a uniform mixed powder, and then the mixed powder is put into the mold, at room temperature Under cold isostatic pressing, followed by hot pressing and sintering for 35 minutes to obtain a high-silicon Al-CNTs master alloy, wherein the hot pressing and sintering temperature is 580° C., and the hot pressing pressure is 25 MPa.

Embodiment 2

[0016] Al-25Si alloy powder and CNTs are used as raw materials (CNTs account for 10wt.% of the total weight of raw materials), and then the prepared raw materials are added to the ball mill under the protection of inert gas for ball milling to obtain a uniform mixed powder, and then the mixed powder is put into the mold , cold isostatic pressing at room temperature, followed by hot pressing and sintering for 30 minutes to obtain a high-silicon Al-CNTs master alloy, wherein the hot pressing sintering temperature is 590°C, and the hot pressing pressure is 15MPa.

Embodiment 3

[0018] Al-20Si alloy powder and CNTs are used as raw materials (CNTs account for 8wt.% of the total weight of raw materials), and then the prepared raw materials are added to a ball mill for vacuum ball milling to obtain a uniformly mixed powder, and then the mixed powder is put into a mold and heated at room temperature Under cold isostatic pressing, followed by hot pressing and sintering for 20 minutes to obtain a high-silicon Al-CNTs master alloy, wherein the hot pressing and sintering temperature is 600° C., and the hot pressing pressure is 5 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com