High-toughness PVC pipe

A PVC pipe, high toughness technology, applied in the field of pipes, can solve the problems of poor thermal stability and light resistance, PVC discoloration, etc., and achieve the effects of good dispersion, good shape, and excellent notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

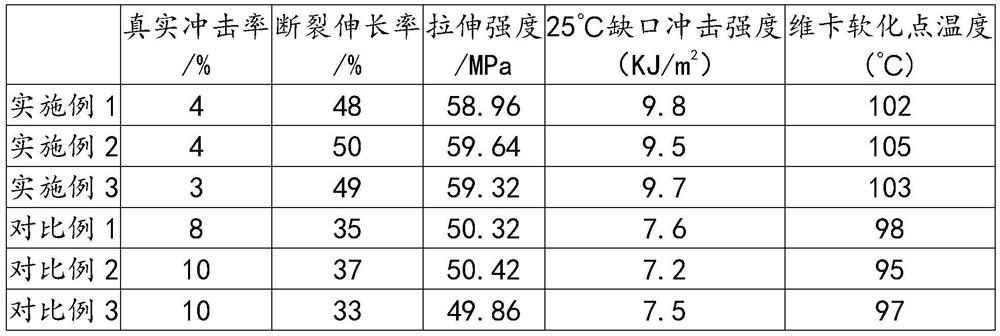

Examples

Embodiment 1

[0029] A kind of high tenacity PVC pipe material, comprises the raw material of following parts by weight:

[0030] 100 parts of modified PVC resin powder, 2 parts of betaine, 1 part of paraffin, 6 parts of heat stabilizer, 2 parts of attapulgite, 6 parts of light calcium carbonate, 1 part of isooctyl tin dimethyl dimercaptoacetate, ortho 1 part of diisobutyl phthalate, 0.5 part of triacetin, 1 part of zinc sulfide and 0.2 part of methyltriethoxysilane;

[0031] The high tenacity PVC pipe is prepared by the following steps:

[0032]The first step is to weigh each raw material according to the weight of the raw materials, add modified PVC resin powder, betaine and paraffin in the stirring tank, stir for 30min at a temperature of 40°C and a stirring speed of 3500r / min, and then Add heat stabilizer, attapulgite, light calcium carbonate, isooctyl tin dimethyldithioglycolate, diisobutyl phthalate, triacetin, zinc sulfide, and methyltriethoxysilane in sequence , keep the temperatu...

Embodiment 2

[0046] A kind of high tenacity PVC pipe material, comprises the raw material of following parts by weight:

[0047] 150 parts of modified PVC resin powder, 3 parts of betaine, 2 parts of paraffin, 8 parts of heat stabilizer, 3 parts of attapulgite, 7 parts of light calcium carbonate, 1 part of isooctyl tin dimethyl dimercaptoacetate, ortho 2 parts of diisobutyl phthalate, 0.6 part of triacetin, 2 parts of zinc sulfide and 0.3 part of methyltriethoxysilane;

[0048] The high tenacity PVC pipe is prepared by the following steps:

[0049] The first step is to weigh each raw material according to the weight of the raw materials, add modified PVC resin powder, betaine and paraffin in the stirring tank, and stir for 35 minutes at a temperature of 45 ° C and a stirring speed of 3500 r / min, and then Add heat stabilizer, attapulgite, light calcium carbonate, isooctyl tin dimethyldithioglycolate, diisobutyl phthalate, triacetin, zinc sulfide, and methyltriethoxysilane in sequence , ke...

Embodiment 3

[0063] A kind of high tenacity PVC pipe material, comprises the raw material of following parts by weight:

[0064] 200 parts of modified PVC resin powder, 4 parts of betaine, 3 parts of paraffin, 10 parts of heat stabilizer, 4 parts of attapulgite, 8 parts of light calcium carbonate, 2 parts of isooctyl tin dimethyl dimercaptoacetate, ortho 3 parts of diisobutyl phthalate, 0.7 parts of triacetin, 3 parts of zinc sulfide and 0.4 parts of methyltriethoxysilane;

[0065] The high tenacity PVC pipe is prepared by the following steps:

[0066]The first step is to weigh each raw material according to the weight of the raw materials, add modified PVC resin powder, betaine and paraffin in the stirring tank, stir for 40min at a temperature of 50°C and a stirring speed of 3500r / min, and then Add heat stabilizer, attapulgite, light calcium carbonate, isooctyl tin dimethyldithioglycolate, diisobutyl phthalate, triacetin, zinc sulfide, and methyltriethoxysilane in sequence , keep the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com