Modified montmorillonite reinforced polyethylene composite material and application thereof in furniture

A technology of composite materials and montmorillonite, which is applied in the field of composite materials and its application in furniture, can solve the problems of decreased mechanical properties, affecting uniformity, poor compatibility, etc., and achieves improved compatibility and excellent affinity , is conducive to the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

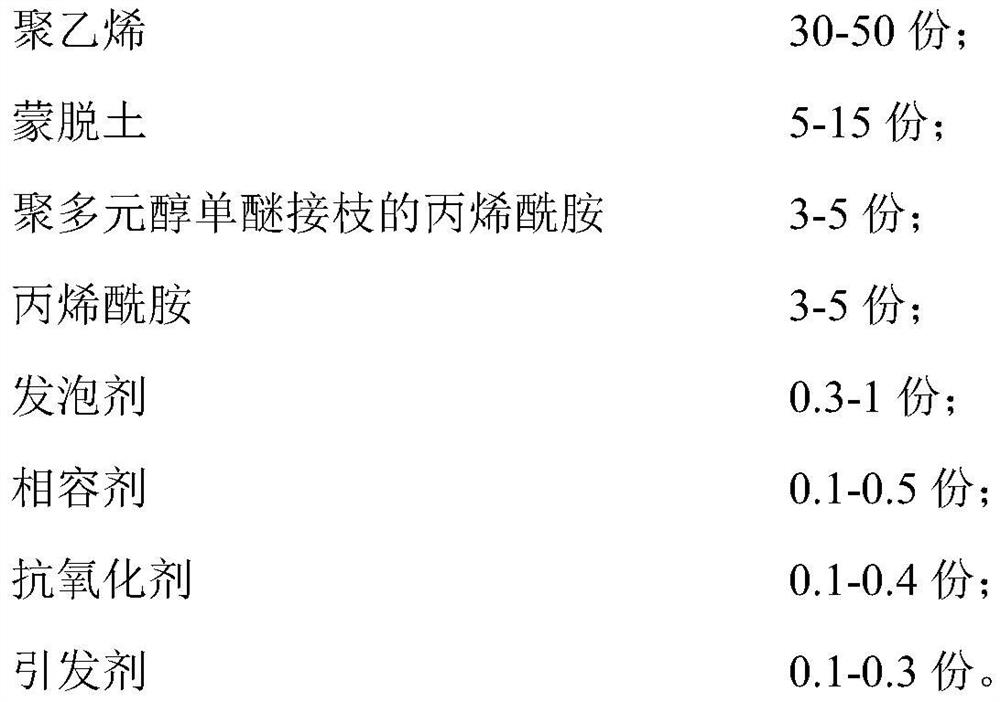

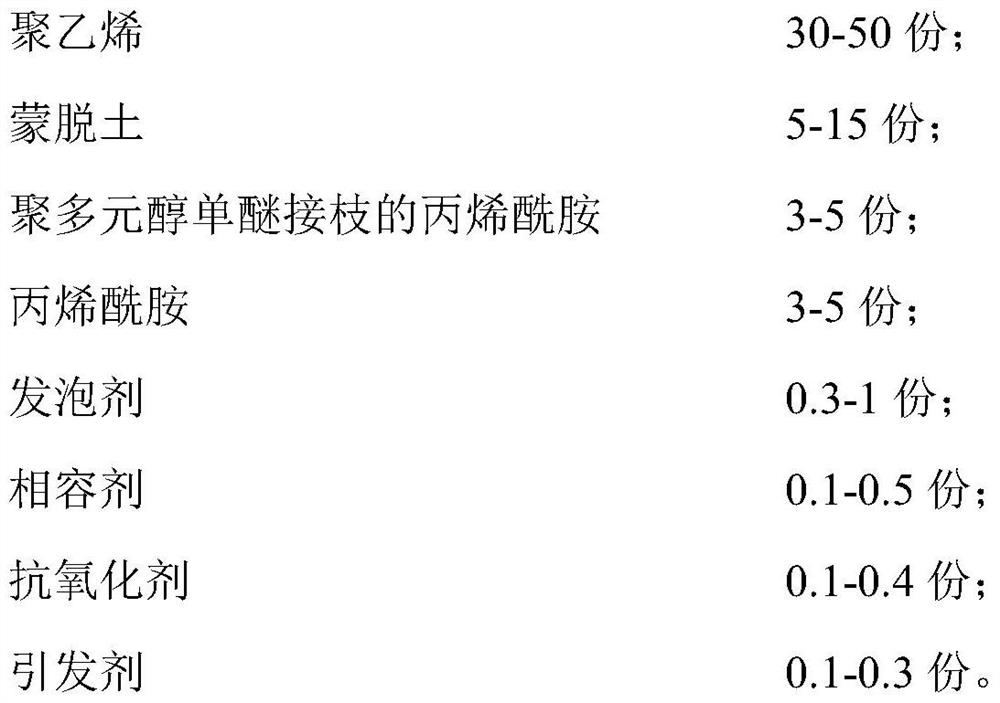

Method used

Image

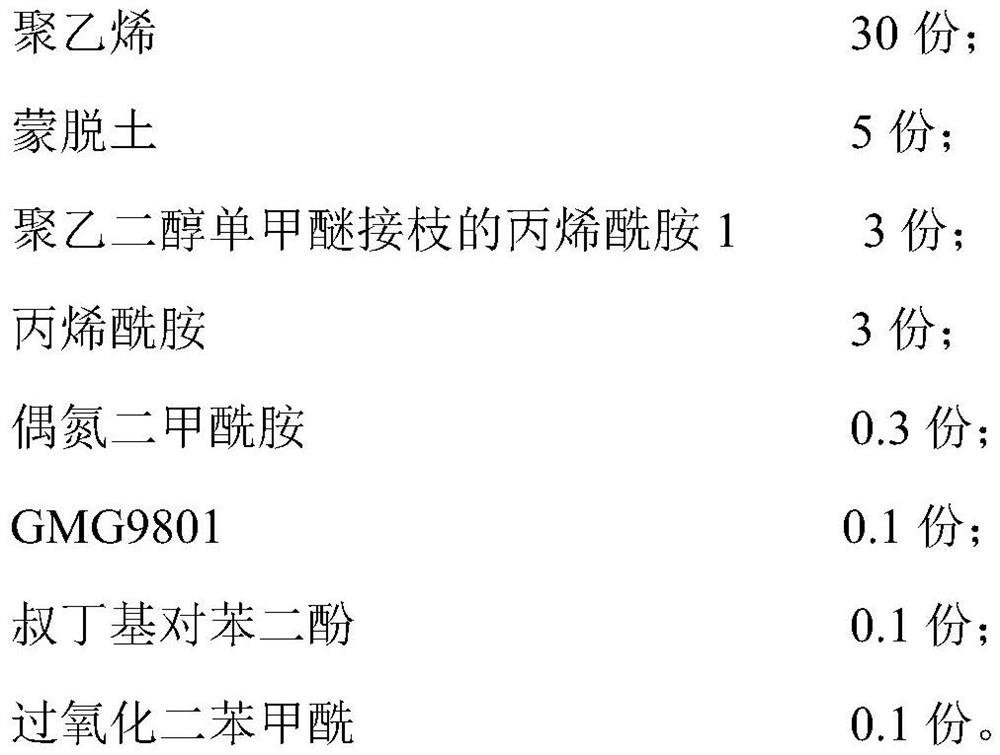

Examples

preparation example 1

[0036]The preparation method of the acrylamide 1 grafted with polyethylene glycol monomethyl ether is as follows: in the reactor, 0.1mol of polyethylene glycol monomethyl ether (wherein, the number of repeating units of polyethylene glycol monomethyl ether is 5), mix with 1mol of acrylamide, then add 20wt% deionized water whose mass is polyethylene glycol monomethyl ether and stir evenly; then heat up to 70°C, add 0.1wt% of polyethylene glycol monomethyl ether Ammonium persulfate and 0.1wt% sodium bisulfite were used as catalysts to react for 3 hours to obtain acrylamide 1 grafted with polyethylene glycol monomethyl ether.

preparation example 2

[0038] The preparation method of the acrylamide 2 grafted with polyethylene glycol monomethyl ether is as follows: in the reactor, the polyethylene glycol monomethyl ether of 0.3mol (wherein, the repeating unit number of polyethylene glycol monomethyl ether is 10), mix with 1mol of acrylamide, then add 40wt% deionized water whose mass is polyethylene glycol monomethyl ether and stir evenly; then heat up to 90°C, add 0.3wt% of polyethylene glycol monomethyl ether Ammonium persulfate and 0.3wt% sodium bisulfite were used as catalysts to react for 5 hours to obtain acrylamide 2 grafted with polyethylene glycol monomethyl ether.

preparation example 3

[0040] The preparation method of the acrylamide 3 grafted with polyethylene glycol monomethyl ether is as follows: in the reactor, the polyethylene glycol monomethyl ether of 0.05mol (wherein, the repeating unit number of polyethylene glycol monomethyl ether is 7), mix with 1mol of acrylamide, then add 30wt% deionized water whose mass is polyethylene glycol monomethyl ether and stir evenly; then heat up to 80°C, add 0.2wt% of polyethylene glycol monomethyl ether Ammonium persulfate and 0.2wt% sodium bisulfite were used as catalysts to react for 5 hours to obtain acrylamide 3 grafted with polyethylene glycol monomethyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com