A preparation method of a modified carbon nanotube negative electrode material

A negative electrode material and carbon nanotube technology, applied in negative electrodes, active material electrodes, battery electrodes, etc., can solve problems affecting uniform dispersion, stability, and poor compatibility, and achieve good electrical conductivity and mechanical strength. Reunion, beneficial to the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

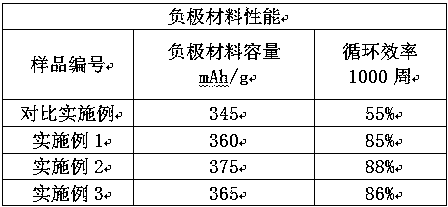

Examples

Embodiment 1

[0021] The preparation method of the modified carbon nanotube negative electrode material in this embodiment, the preparation method comprises the following steps:

[0022] (1) Mix 2g polyethylene glycol and 10g carbon nanotube material in 20g water to obtain mixture A;

[0023] (2) Mixture A was stirred at 20°C for 2 hours and then filtered to obtain mixture B;

[0024] (3) centrifuging the mixture B to obtain the modified carbon nanotube material;

[0025] (4) Prepare the modified carbon nanotube material and the graphite negative electrode material according to the ratio of 1:30 to form a mixed solution of ethanol with a solid content of 25%;

[0026] (5) After the mixed solution was centrifuged, the solid was dried at 50°C for 5 hours and used as the negative electrode material of the battery.

Embodiment 2

[0028] The preparation method of the modified carbon nanotube negative electrode material in this embodiment, the preparation method comprises the following steps:

[0029] (1) Mix 0.2g polyethylene glycol and 20g carbon nanotube material in 50g water to obtain mixture A;

[0030] (2) Mixture A was stirred at 90°C for 1 hour and then filtered to obtain mixture B;

[0031] (3) centrifuging the mixture B to obtain the modified carbon nanotube material;

[0032] (4) Prepare the modified carbon nanotube material and the graphite negative electrode material according to the ratio of 1:4 to form an ethanol mixed solution with a solid content of 25%;

[0033] (5) After centrifuging the mixed solution, take the solid and dry it at 300°C for 1 hour and use it as the negative electrode material of the battery.

Embodiment 3

[0035] The preparation method of the modified carbon nanotube negative electrode material in this embodiment, the preparation method comprises the following steps:

[0036] (1) Mix 1g polyethylene glycol and 10g carbon nanotube material in 30g water to obtain mixture A;

[0037] (2) Mixture A was stirred at 50°C for 1.5h and then filtered to obtain mixture B;

[0038] (3) centrifuging the mixture B to obtain the modified carbon nanotube material;

[0039] (4) Prepare the modified carbon nanotube material and the graphite negative electrode material according to the ratio of 1:10 to form a mixed solution of ethanol with a solid content of 25%;

[0040] (5) After the mixed solution was centrifuged, the solid was dried at 200°C for 2 hours and used as the negative electrode material of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com