Preparation method of hierarchical porous carbon particles based on phase inversion

A technology of multi-level pores and particles, applied in the preparation/purification of carbon, etc., can solve the problems of difficult industrial mass production, unfavorable practical application, harsh operating conditions, etc., and achieve adjustable size and shape, low equipment requirements, and easy particle formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

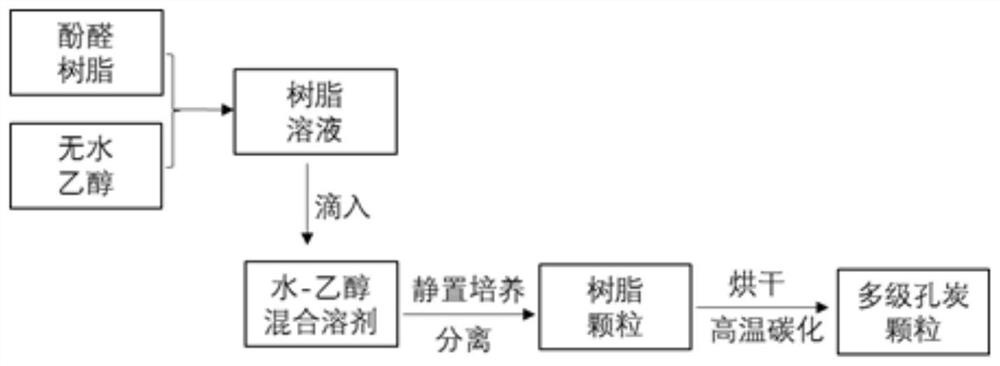

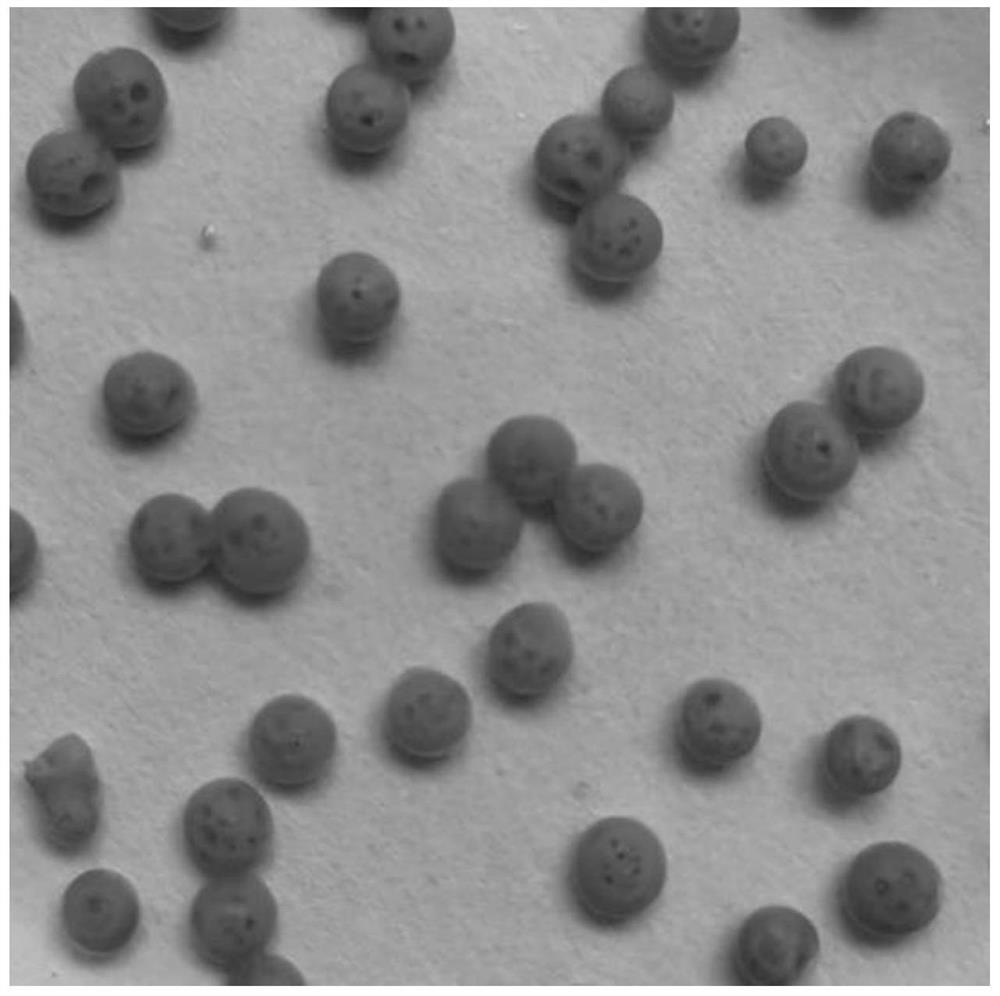

[0020] Specific embodiment 1: a kind of preparation method of hierarchical porous carbon particles, as attached figure 1 shown. The phenolic resin-ethanol solution is dropped into the water-ethanol mixed solvent, the phenolic resin solidifies with water to form granules, and is cultivated until the granules are completely solidified, then dried and carbonized to obtain the product. Concrete steps are as follows: (1) 4g phenolic resin and 1g dehydrated alcohol are added in the beaker and stirred 30min, form uniform phenolic resin-ethanol solution; 4g of pure water and 2g of absolute ethanol) in a petri dish. Since phenolic resin is insoluble in water, it solidifies in water to form spherical particles, and it is incubated at 40°C for 12 hours to obtain pale pink porous phenolic resin particles, such as figure 2 (3) Take out the phenolic resin particles and dry them in a constant temperature oven at 100°C for 2 hours; (4) Move the phenolic resin particles into a crucible and ...

specific Embodiment 2

[0021] Specific embodiment 2: a kind of preparation method of hierarchical porous carbon particles, as attached figure 1 shown. The phenolic resin-ethanol solution is dropped into the water-ethanol mixed solvent, the phenolic resin solidifies with water to form granules, and is cultivated until the granules are completely solidified, then dried and carbonized to obtain the product. The specific steps are as follows: (1) 16g phenolic resin and 4g absolute ethanol are added in the beaker and stirred for 30min to form a uniform phenolic resin-ethanol solution; mixed with pure water and 5g of absolute ethanol) in a petri dish. Since phenolic resin is insoluble in water, it solidifies in water to form spherical particles, and cultures at 40°C for 12 hours to obtain pale pink porous phenolic resin particles; (3) Take out the phenolic resin particles and dry them in a constant temperature oven at 100°C for 3 hours (4) Move the phenolic resin granules into the crucible, place them i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com