A chromium-doped titanium dioxide nanotube-amino-modified graphene oxide composite material and its preparation method and application

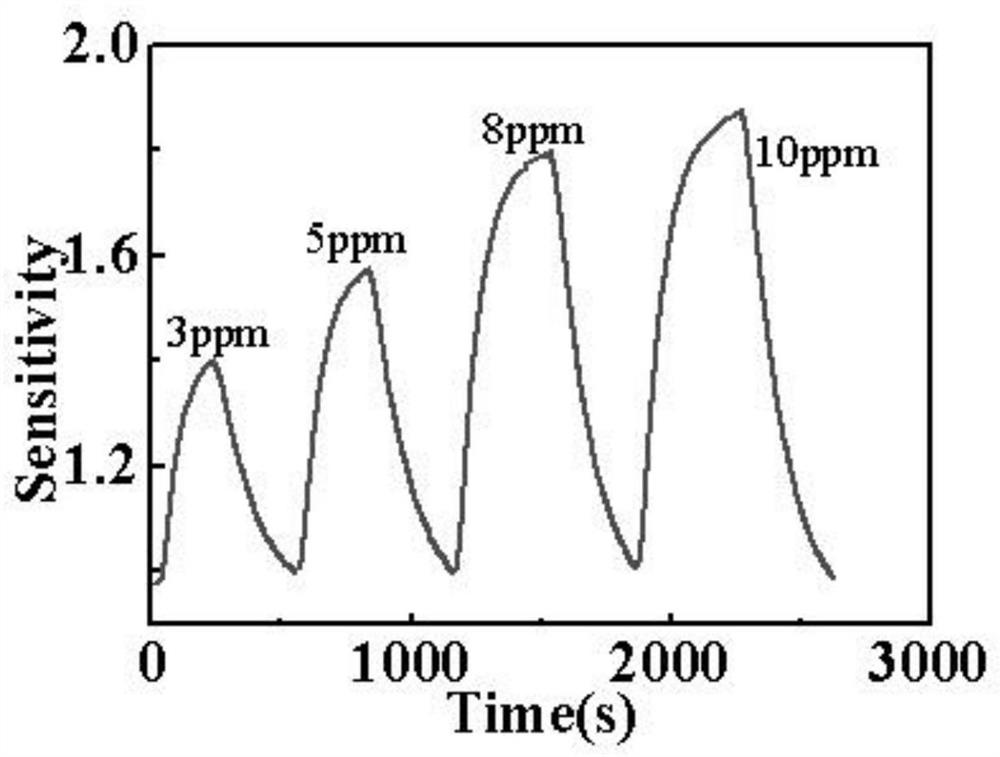

A technology of titanium dioxide and amino modification, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, analytical materials, etc., can solve the problem of poor detection of acetone and achieve improved gas-sensing performance, Effects of improving sensitivity and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of the chromium-doped titanium dioxide nanotube-amino-modified graphene oxide composite material described in the above technical solution, comprising the following steps:

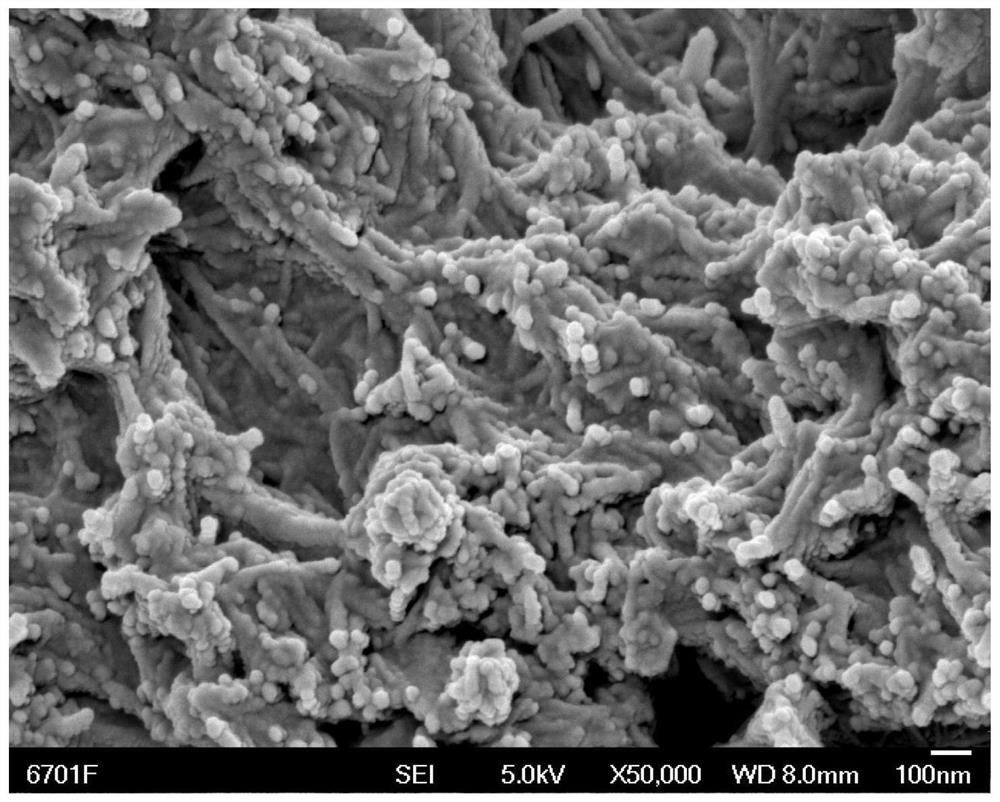

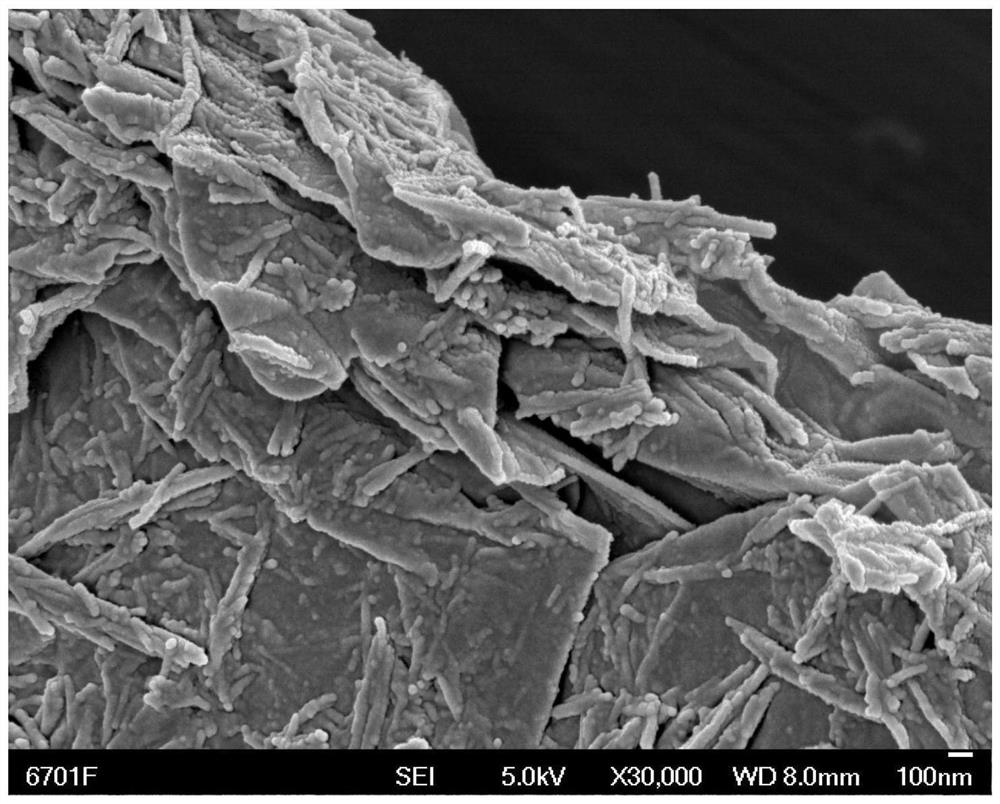

[0027] Mixing strong alkali, titanium dioxide particles, water-soluble chromium salt and water to form a precursor solution; performing a hydrothermal reaction on the precursor solution to obtain a hydrothermal reaction solution; centrifuging the precipitate obtained from the hydrothermal reaction solution for washing , drying and sintering to obtain chromium-doped titania nanotubes;

[0028] Using the improved Hummers method to prepare graphene oxide to obtain graphene oxide; modifying the graphene oxide with ethylenediamine to obtain amino-modified graphene oxide;

[0029] Mixing the chromium-doped titanium dioxide nanotubes with N,N-dimethylformamide to obtain a chromium-doped titanium dioxide nanotube solution; mixing the amino-modified gr...

Embodiment 1

[0073] Step 1 Preparation of chromium-doped titania nanotubes

[0074] 20g sodium hydroxide and 50mL deionized water were stirred for 10min to obtain a NaOH solution with a concentration of 10mol / L, and 1g nano-TiO 2 Add the particles into the NaOH solution, sonicate for 5 minutes, and continue to stir for 20 minutes to obtain a titanium dioxide solution; dissolve 1.5 g of chromium nitrate hexahydrate in 28 mL of deionized water, and stir mechanically for 10 minutes to obtain a chromium nitrate solution; add the chromium nitrate solution dropwise to the titanium dioxide solution , the dropwise addition is completed within 5 minutes, and the stirring is continued for 25 minutes to obtain a precursor solution;

[0075] Pour all the precursor solution into a 100mL reaction kettle, place it in an oven at 150°C and heat it for 20h (hydrothermal reaction). Put the hydrothermal reaction liquid into a 500mL beaker, first wash the product with 1% hydrochloric acid, adjust the pH value...

Embodiment 2

[0085] Step 1 Preparation of chromium-doped titania nanotubes

[0086] Add 2g of sodium hydroxide to 50mL of deionized water, and stir mechanically for 10min to obtain a NaOH solution with a concentration of 1mol / L. Add 0.1g of nano-TiO 2 Add the particles into the NaOH solution, sonicate for 5 minutes, and continue to mechanically stir for 20 minutes to obtain a titanium dioxide solution; dissolve 0.15 g of chromium nitrate hexahydrate in 20 mL of deionized water, and mechanically stir for 10 to obtain a chromium nitrate solution; add the chromium nitrate solution dropwise to the titanium dioxide solution During the process, the dropwise addition is completed within 5 minutes, and the mechanical stirring is continued for 25 minutes to obtain the precursor solution;

[0087] Pour all the precursor solution into a 100mL reaction kettle, place it in an oven at 160°C and heat it for 24h (hydrothermal reaction). Put the hydrothermal reaction liquid into a 500mL beaker, first wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com