Corrosion inhibitor and application thereof

A technology of corrosion inhibitor and pickling corrosion inhibitor, which is applied in the field of materials, can solve the problems of hindering the reaction of hydrogen ions and iron matrix, and achieve the effect of ensuring decontamination, simple process and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

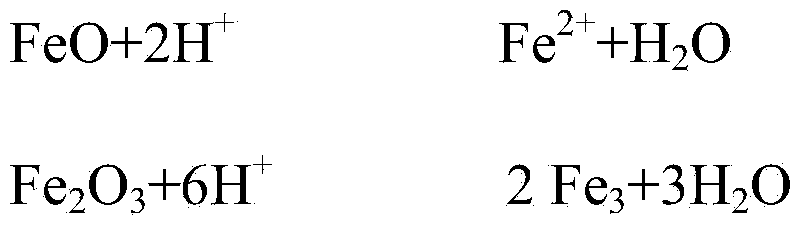

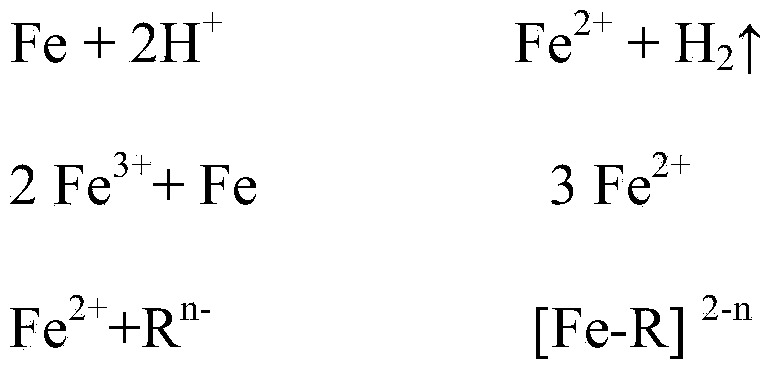

Method used

Image

Examples

Embodiment Construction

[0024]

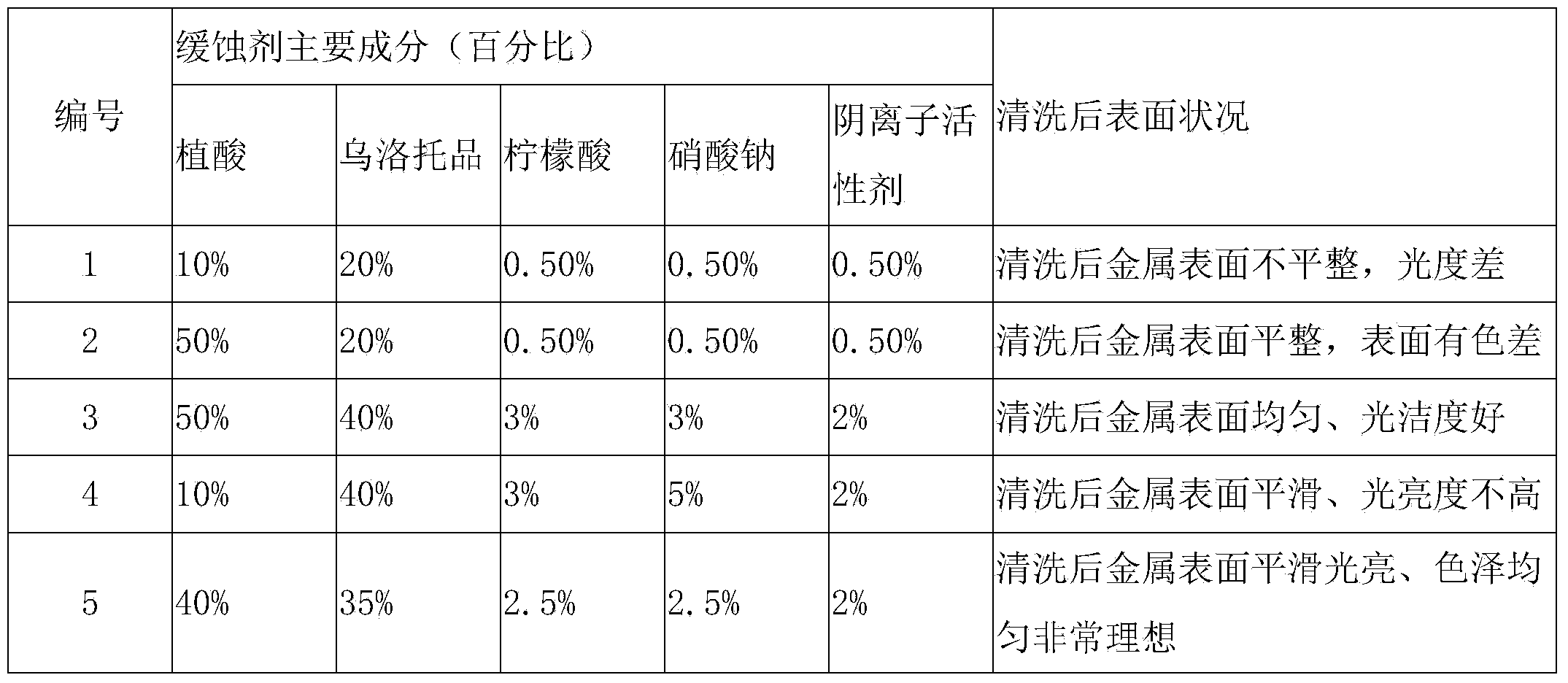

[0025] Comparative Experiment

[0026] Experimental location: Steel Rolling Analysis Center, Quality Inspection Department, Manufacturing Department, Shougang Jingtang Company;

[0027] Purpose:

[0028] 1. Qualitative evaluation and comparison of the improvement of the surface quality of steel coils by two corrosion inhibitors;

[0029] 2. Qualitatively evaluate and compare the effects of two corrosion inhibitors on reducing bubbles, and observe the foam generation;

[0030] 3. Quantitatively calculate and compare the corrosion inhibition efficiency of two corrosion inhibitors;

[0031] Experimental procedure

[0032] Table 1 Preparation before experiment

[0033]

[0034]

[0035] experiment process

[0036] Add 500mL of acid solution to three 600ml beakers in equal amounts and heat in an electric water bath to maintain the temperature at 80°C. After the temperature stabilized, one beaker was used as a blank sample, and Jinkejing corrosion inhibitor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com