Method for air tightness hard packaging of sensitive chip of piezoresistive pressure sensor

A pressure sensor and sensitive chip technology, which is applied in the direction of fluid pressure measurement by changing ohmic resistance and the measurement of the property force of piezoelectric resistance materials. It can solve the problems of chip detachment and failure, improve stability and avoid internal Effects of Pressure Transfer Fluid Leakage Failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

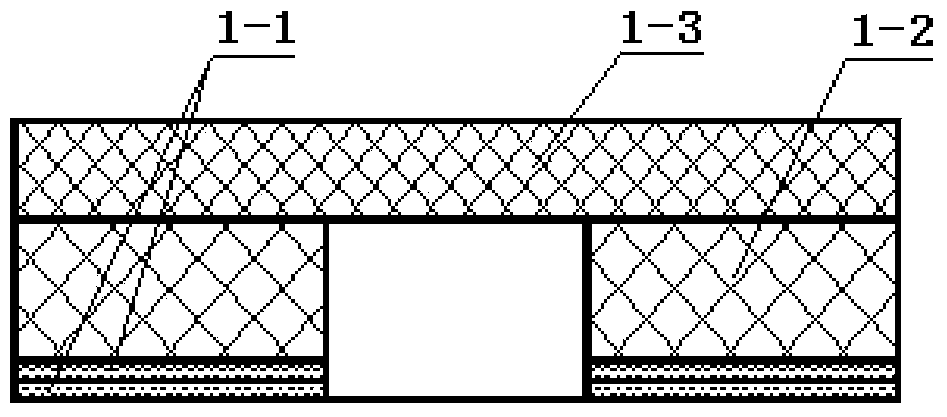

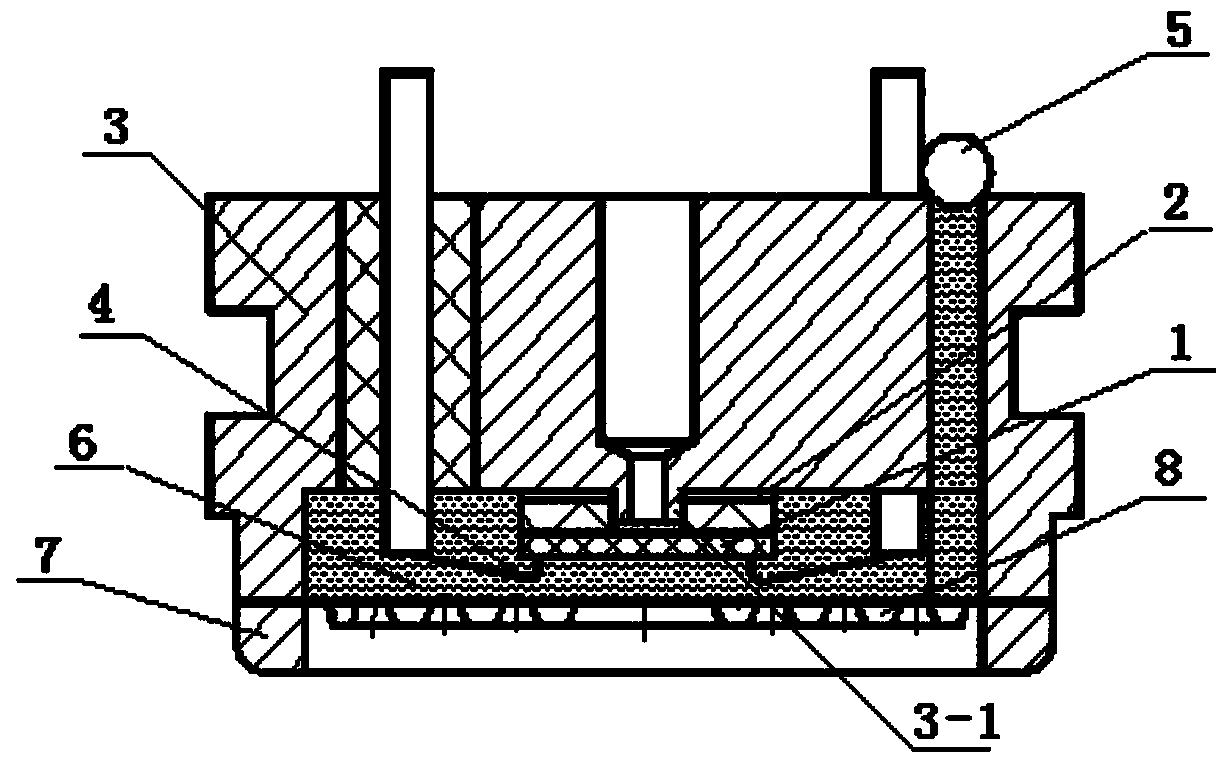

[0014] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the airtight hard packaging method of the sensitive chip of the piezoresistive pressure sensor in this embodiment, proceed according to the following steps:

[0015] 1. Firstly deposit Cr, Pt, and Au by magnetron sputtering on the bottom surface of the sensitive chip 1 to obtain the metal layer 1-1;

[0016] 2. At the position where the tube base assembly 3 of the piezoresistive pressure sensor is connected to the sensitive chip 1, a positioning boss 3-1 is provided, and the brazing pad 2 matches the shape of the sensitive chip 1, and is brazed There is a hole matching the positioning boss 3-1 in the middle of the soldering piece 2, and the sensitive chip 1, the brazing soldering piece 2, and the socket assembly 3 are stacked in order from top to bottom, and the front of the sensitive chip 1 is facing upwards. The brazing pad 2 passes through the positioning boss 3-1 through the...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that: the melting point of the brazing sheet 2 in Step 2 is 210-230°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the brazing sheet 2 in step 2 is tin-silver-copper alloy SAC305. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com