Non-active double-layer containment with water storage steel pipe column

A technology of double-layer containment and steel pipe columns, applied in nuclear power generation, climate sustainability, emergency protection devices, etc., can solve problems such as no significant progress, unfavorable structure anti-seismic, etc., and achieve improved survivability and good waste heat discharge performance , Improve the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

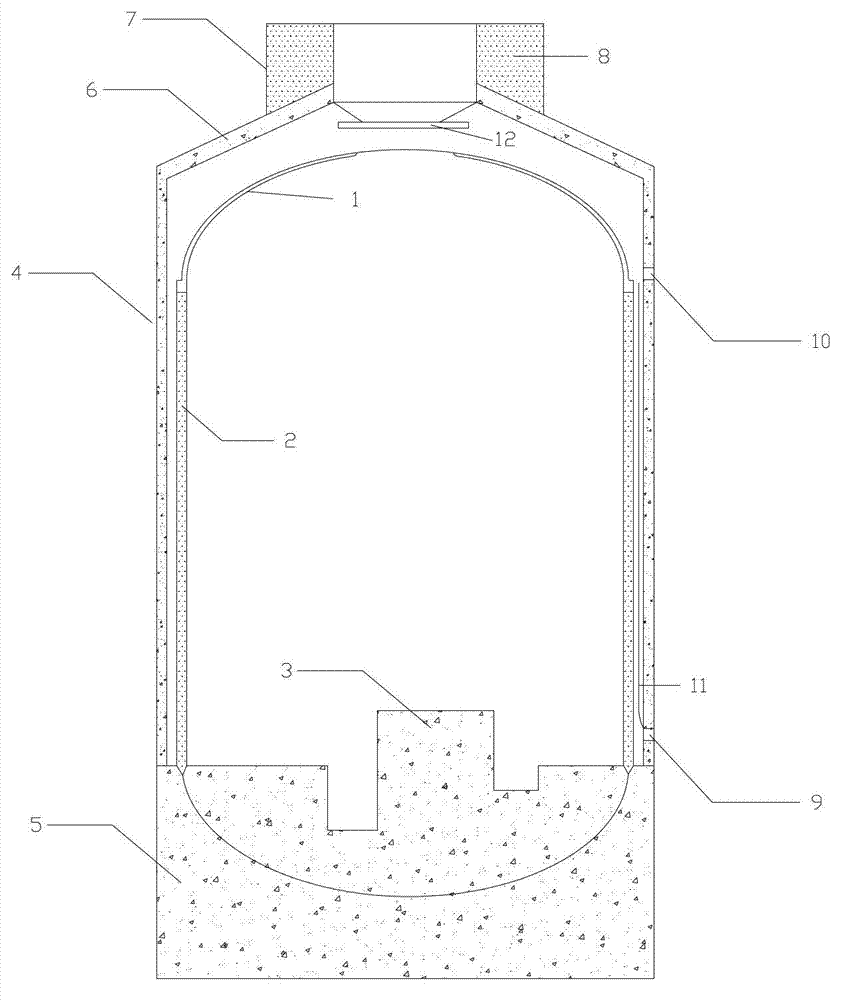

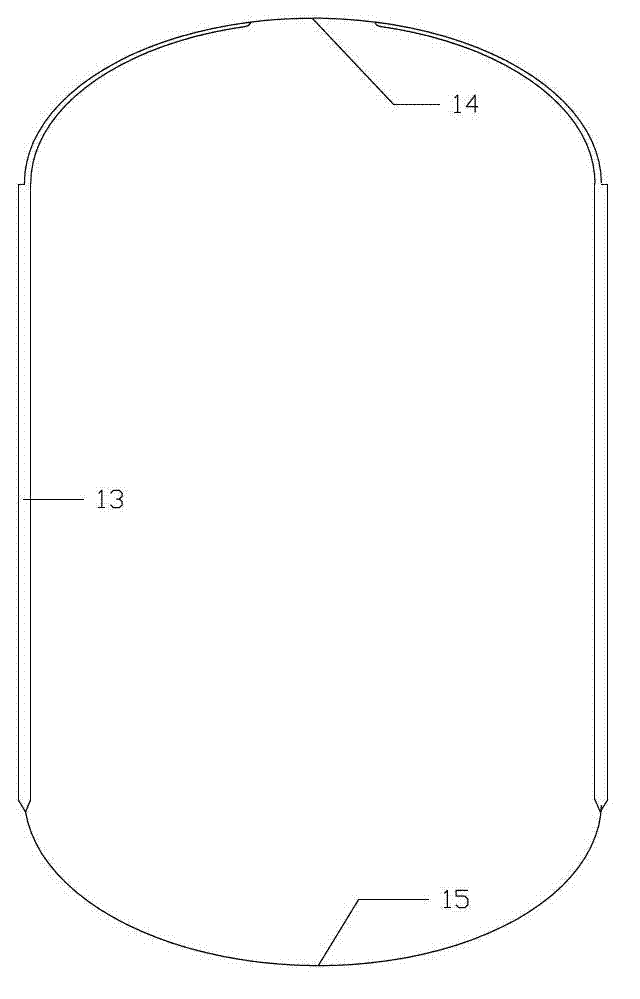

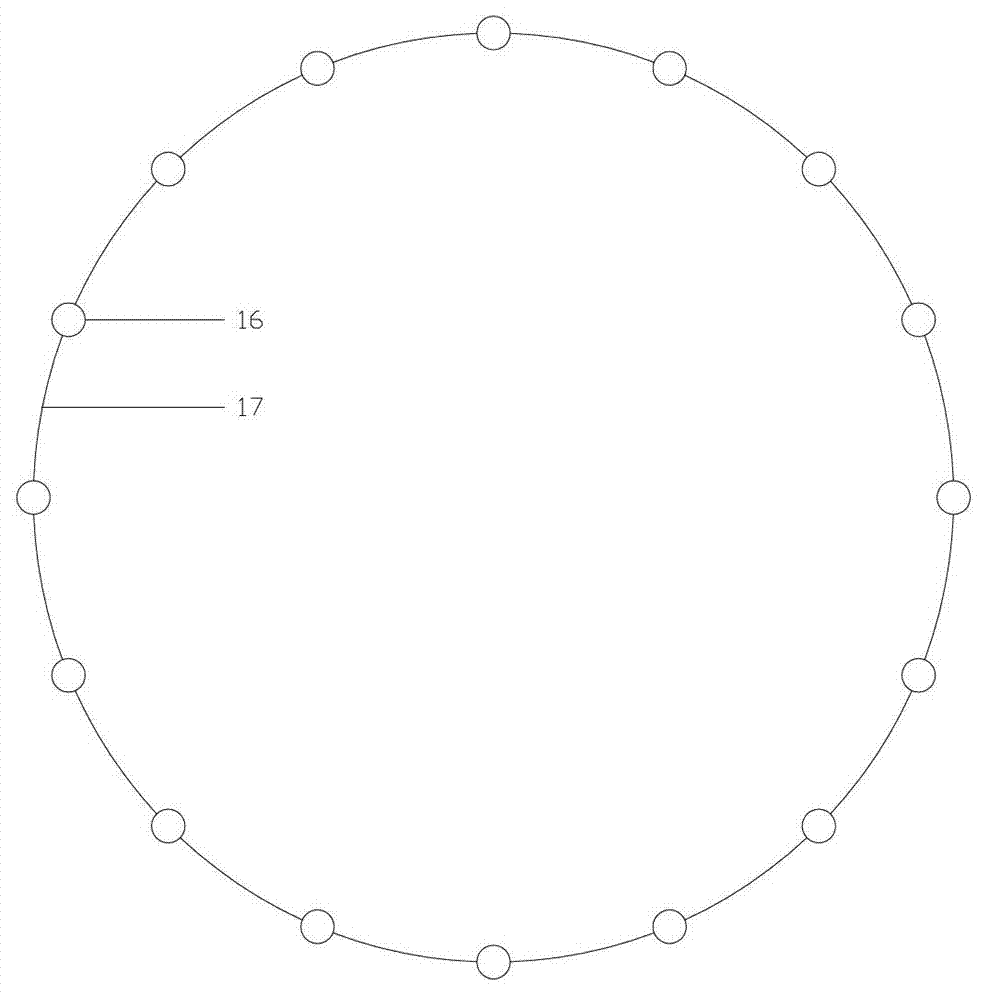

[0029] like figure 1 As shown, the passive double-layer containment vessel with water storage steel pipe column in the present invention includes a steel containment vessel 1, inter-column cooling water 2, outer plate 4, bottom plate 5, roof plate 6, upper cooling water tank 7, and upper cooling water 8 , the lower air intake hole 9, the upper exhaust hole 10, the air deflector 11, the flow distribution plate 12;

[0030] The base plate 5 is located on the foundation; the steel containment vessel 1 is located on the base plate 5; the outer plate 4 is arranged on the outside of the steel containment vessel 1, the outer plate 4 is located on the base plate 5, and the outer plate 4 and the base plate 5 are connected by inserting ribs; A top plate 6 is arranged on the plate 4, and the upper cooling water tank 7 is located on the top plate 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com