Control System Of Variable Speed Pumped Storage Hydropower System And Method Of Controlling The Same

A technology of pumping water power generation and control device, which is applied in generator control circuits, hydropower generation, and control of generators through magnetic field changes, and can solve problems such as the reduction of pump turbine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

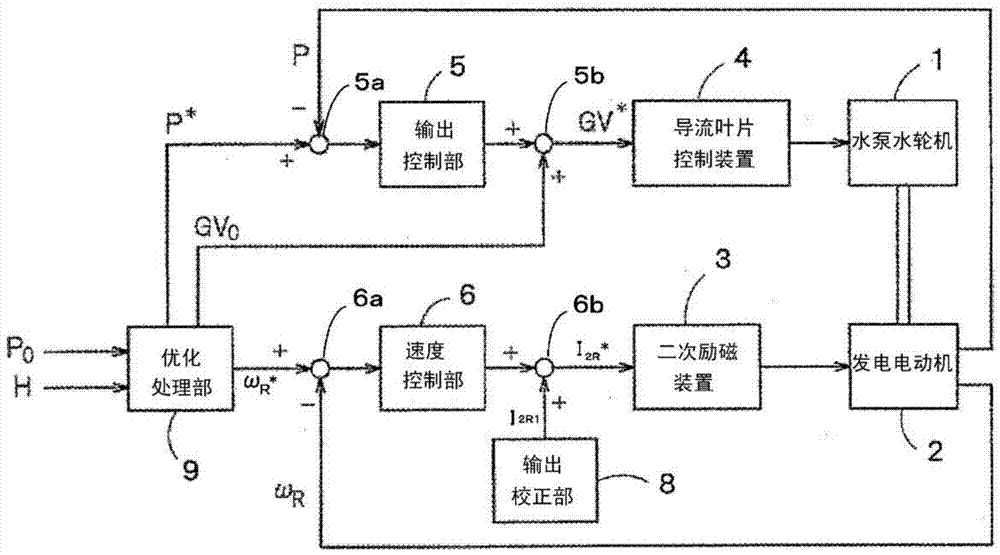

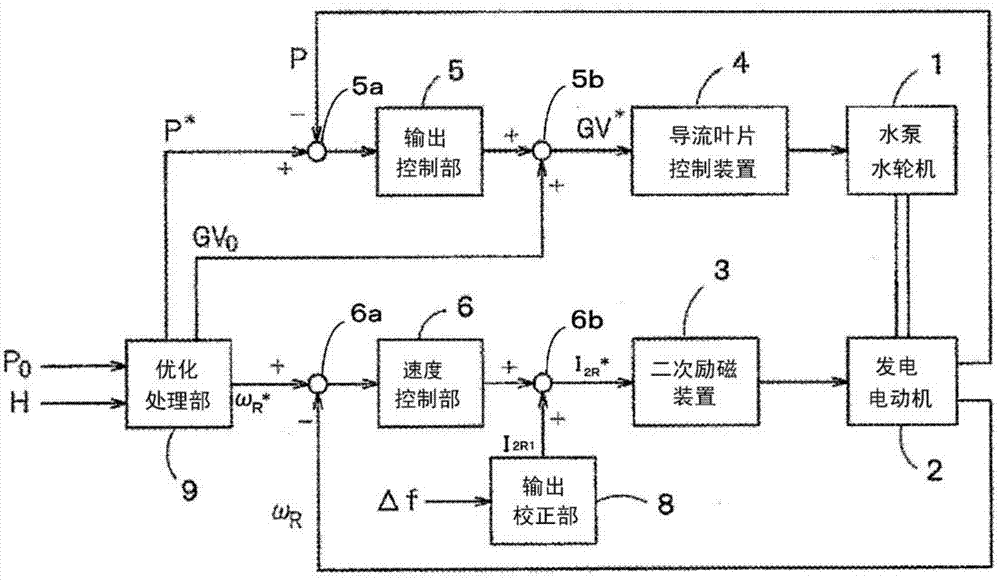

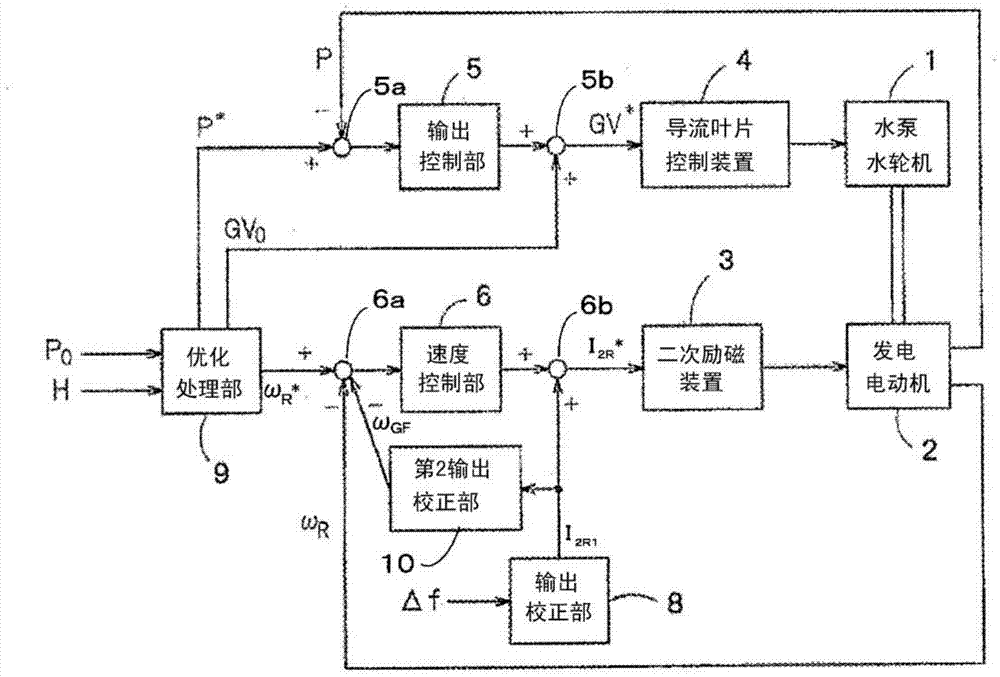

[0090] refer to Figure 1A ~ Figure 1D , Figure 2 to Figure 5 as well as Figure 9 , the first embodiment will be described.

[0091] Figure 1A ~ Figure 1D It is a figure which shows an example (part 1 - part 4) of the schematic structure of the variable-speed pumping power generation system of 1st Embodiment. also, Figure 9 for Figure 1D The detailed structure diagram of the variable speed pumping power generation system shown.

[0092] The variable speed pumping power generation system is a system that can make the generator motor run at a non-synchronous speed, including: the pump turbine 1, which is directly connected to the generator motor 2; the generator motor 2; the secondary excitation device 3, which flows through the secondary winding of the generator motor 2 overcurrent; the guide vane control device 4 controls the opening of the guide vane (guide vane) controlling the flow of the pump turbine 1; the output control unit 5 is based on the generator motor o...

no. 2 approach )

[0128] Refer to the above Figure 1A ~ Figure 1D , Figure 2 to Figure 5 , the second embodiment will be described. Hereinafter, the description of the parts common to the first embodiment will be omitted.

[0129] In the present embodiment, the optimization processing unit 9 outputs the command value P * and generator motor output demand value P 0 The generator motor output demand value P is extracted from the difference of 0 rapidly changing components. Then, the extracted high-speed change components are used as the effective part of the generator-motor secondary current I 2R0 correction value.

[0130] Even if the opening of the guide vane is equal to the required output value of the generator motor P 0 Therefore, the effect cannot be expected, and it will only cause mechanical stress (stress) or wear of the guide vane and its driving mechanism, so this situation is being avoided. The effective part I of the secondary current of the generator motor without limiting...

no. 3 approach )

[0132] further reference Figure 6 , the third embodiment will be described. Hereinafter, descriptions of parts common to the first embodiment and the second embodiment are omitted.

[0133] Figure 6 is expressed as ω of the third embodiment 2 It is a diagram showing an example of the circuit configuration related to the control unit 106 . Should Figure 6 The circuit configuration is equivalent to that described in Figure 4 A modified example of the circuit configuration on the lower side. exist Figure 6 In, a response adjuster 133 is also provided.

[0134] Figure 6 The response regulator 141, ω 2 controller 142 are respectively equivalent to Figure 4 Response modifier 126, ω in 2 Controller 127.

[0135] In the present embodiment, the response adjuster 133 converts the system frequency deviation Δf into the generator motor output, and obtains the change amount of the generator motor output which changes rapidly. In addition, whether it is desired to increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com