apfc constant current controller integrated circuit

A technology of integrated circuits and flow controllers, which is applied in the field of driving devices and APFC constant current controller integrated circuits, can solve the problems of not increasing the manufacturing cost and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

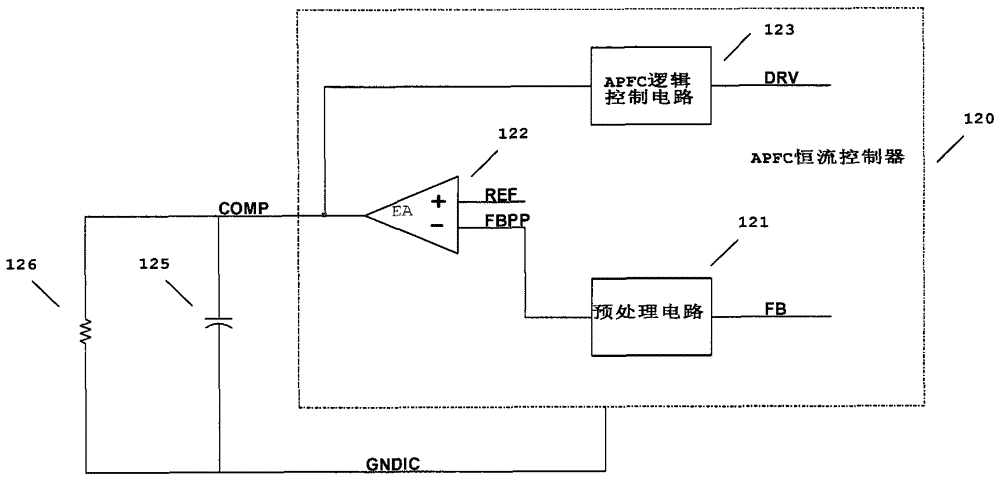

[0044] As mentioned above, in order to ensure the stable operation of the drive circuit, APFC technology requires that the unity gain bandwidth of the feedback control loop must be below 10Hz, which makes the capacitance of the frequency compensation capacitor larger, generally around 1uF. Those skilled in the art understand that it is unrealistic to directly integrate a 1uF capacitor into the chip. According to the level of modern microelectronic semiconductor technology, only 1uF capacitor needs 100mm 2 The silicon chip area above is equivalent to the silicon chip area of the most advanced computer CPU of the time. This is not possible due to the high cost.

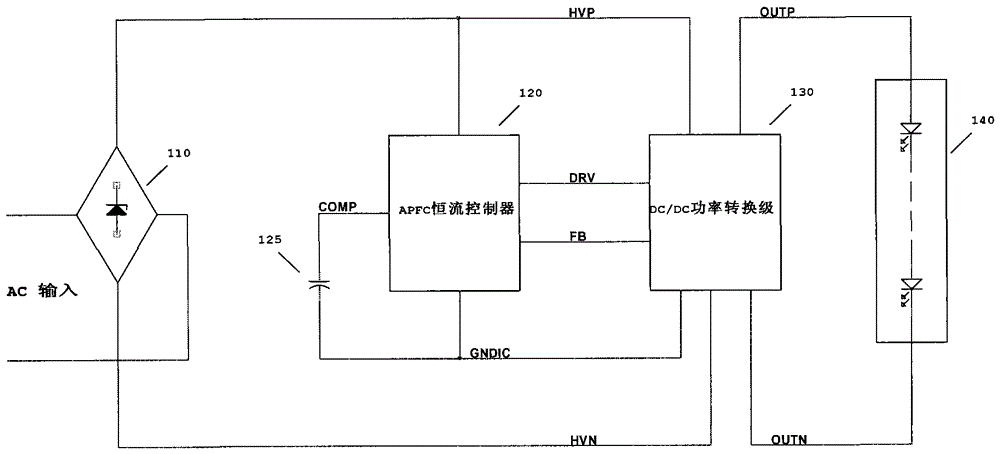

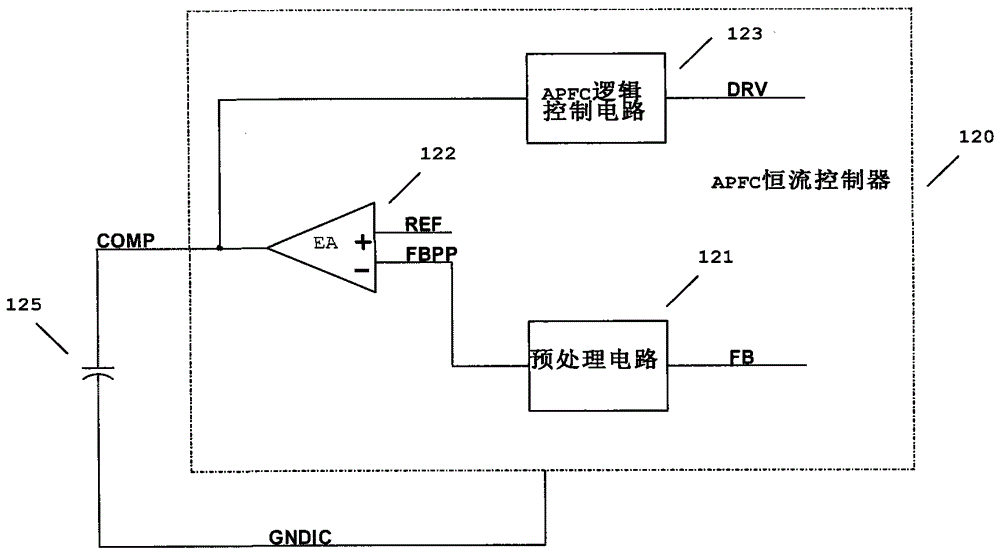

[0045] refer to Figure 4 , Figure 4 The structure of the integrated circuit of the APFC constant current controller according to an embodiment of the present invention is shown. In this embodiment, the preprocessing circuit 121 and the APFC logic control circuit 123 still maintain figure 2 The structure and fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com