An image processor

A technology for processing machines and imaging, applied in photography, progressive mechanical conveying of liquid materials for exposure, photosensitive materials, etc. It can solve problems such as improper temperature control, image forming effect, film temperature distortion, etc. , to solve the moist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

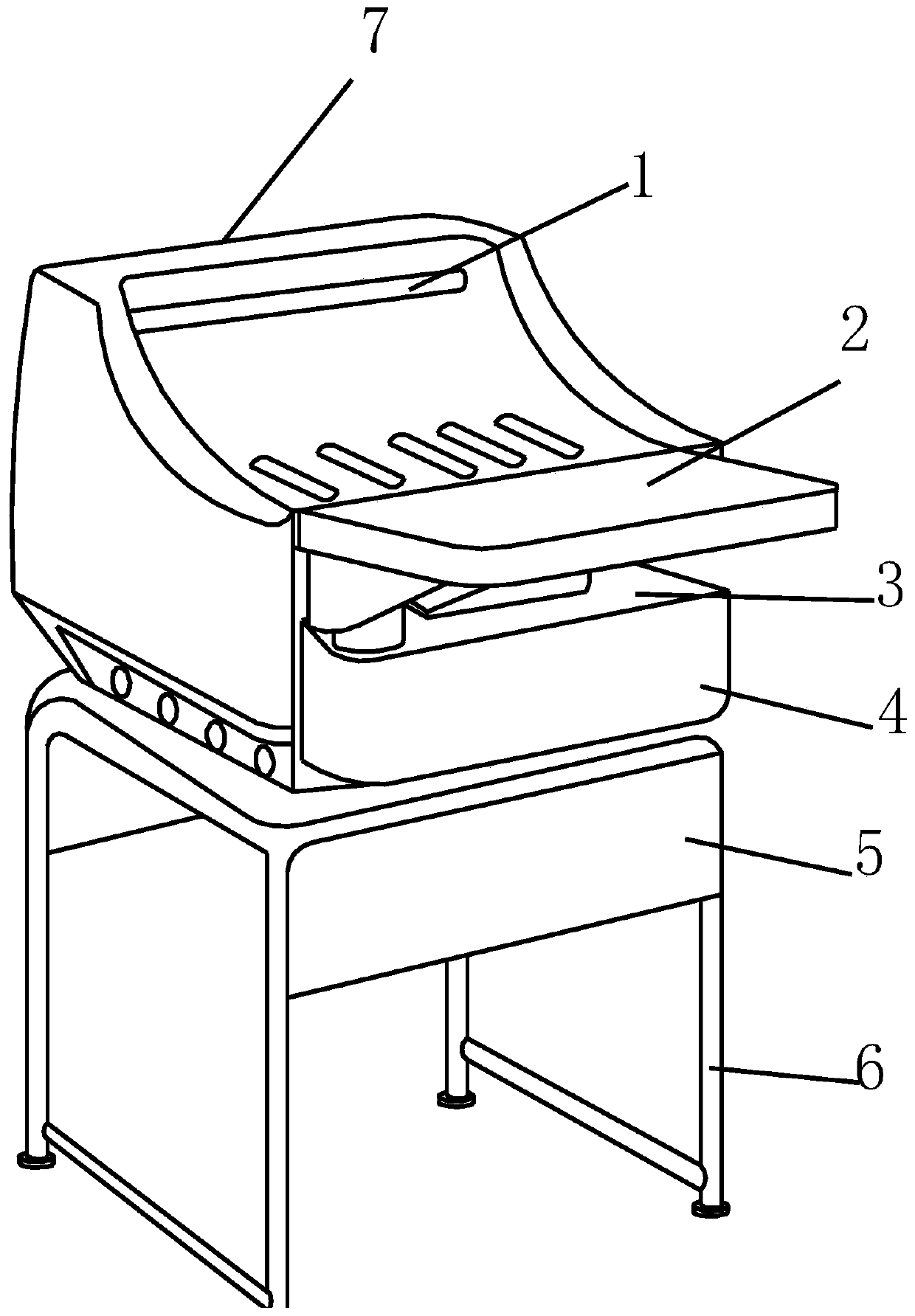

[0024] see Figure 1-Figure 6 , the present invention provides a film developing machine for imaging department, its structure includes a film outlet 1, a placement table 2, a film inlet 3, a transmission drying mechanism 4, a machine table 5, supporting feet 6, and a housing 7. The four corners of the bottom end of the machine table 5 are welded with legs 6, the housing 7 is placed on the machine table 5, the table 2 is placed on the housing 7, and the film outlet 1 is arranged above the table 2. A film feeding port 3 is provided under the placing table 2, and a transmission drying mechanism 4 and a motor are provided inside the housing 7, and the transmission drying mechanism 4 is mechanically connected to the motor.

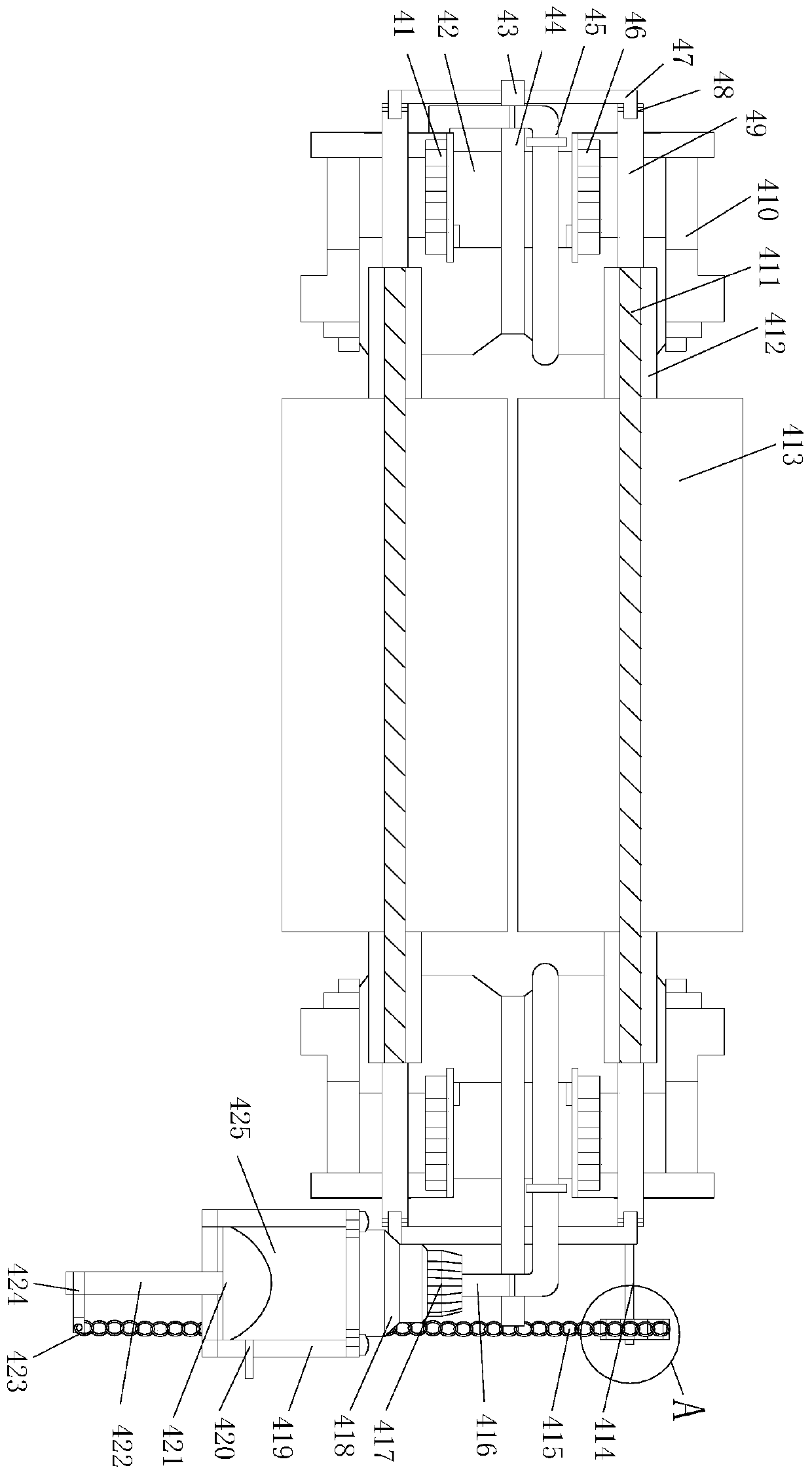

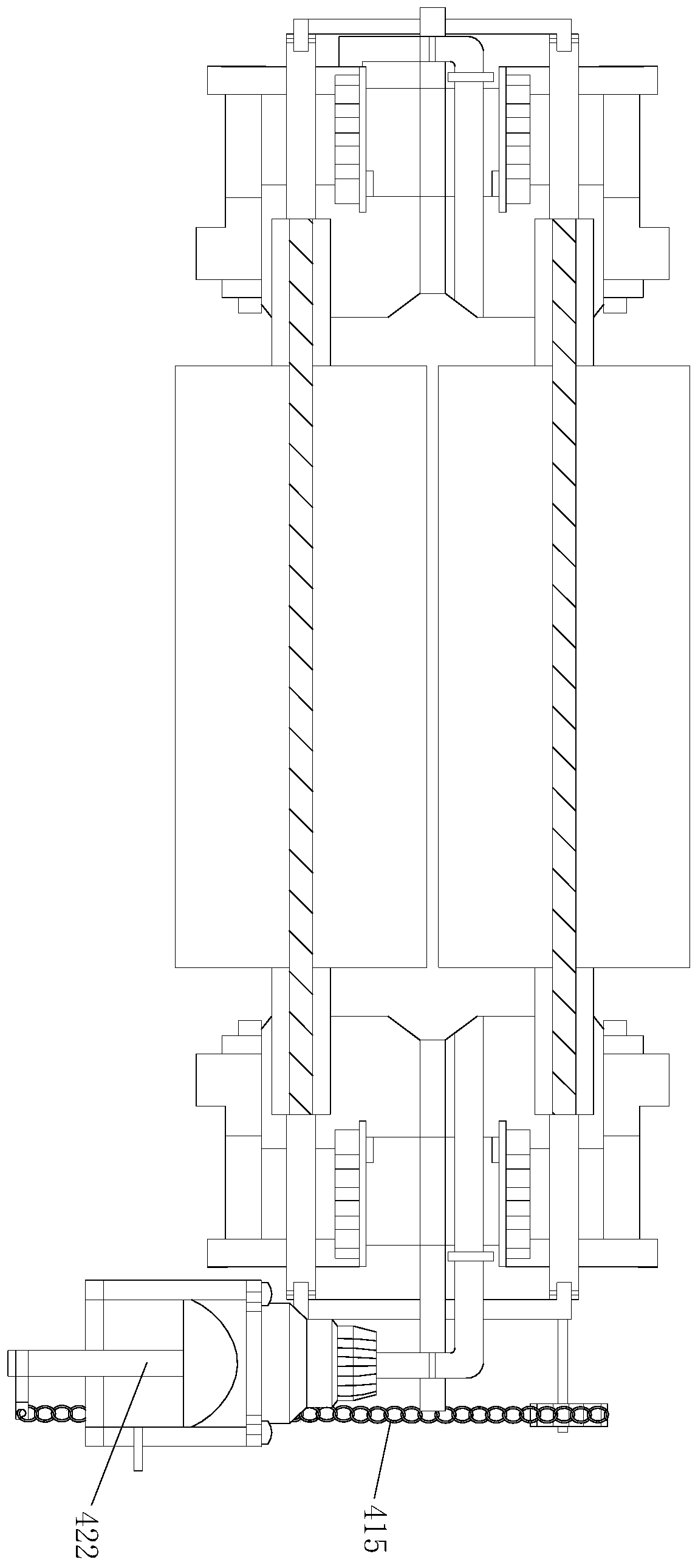

[0025] The transmission drying mechanism 4 is provided with a first threaded connection cylinder 41, a connection column 42, a connection shaft 43, a support plate 44, a first connection pipe 45, a second threaded connection cylinder 46, a first transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com