Reinforcing laminating device for flexible printed circuit board

A technology of flexible circuit boards and laminating devices, which is applied in the direction of printed circuits, printed circuit manufacturing, and electrical components, can solve problems such as unfavorable storage and storage, increased transit labor, and scattered paper sheets, so as to achieve ventilation and transmission functions and improve Fitting accuracy and the effect of reducing transit time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

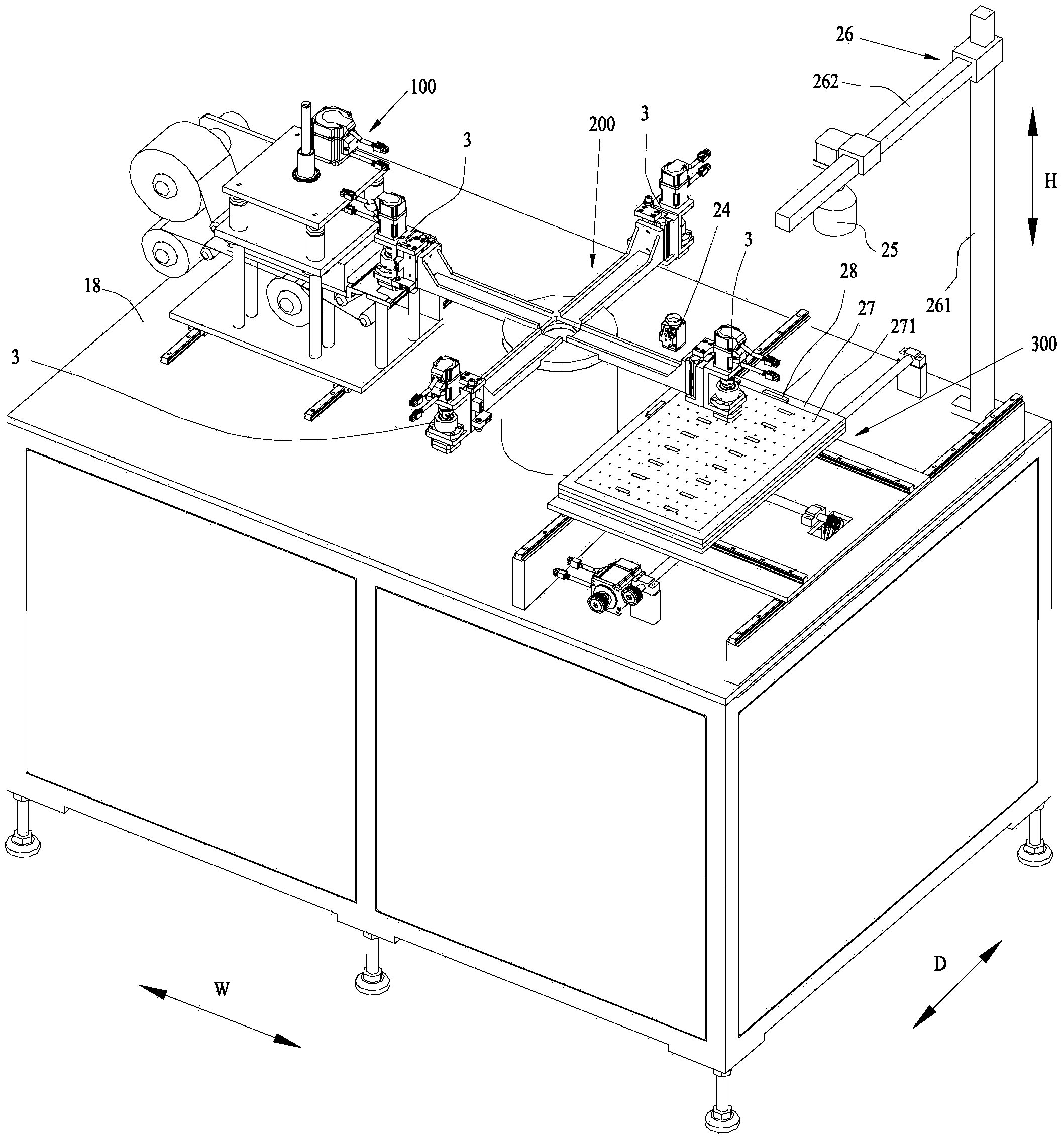

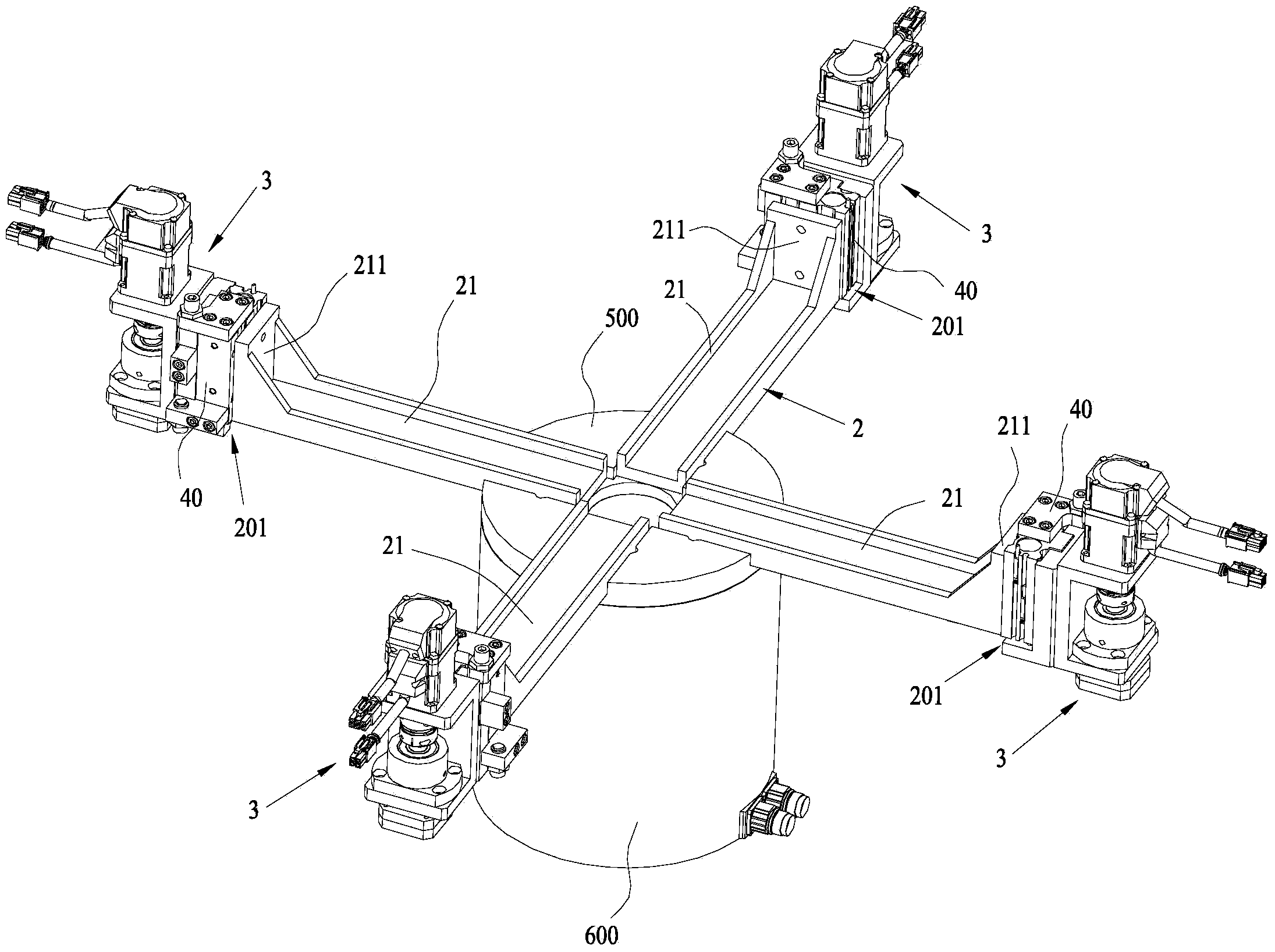

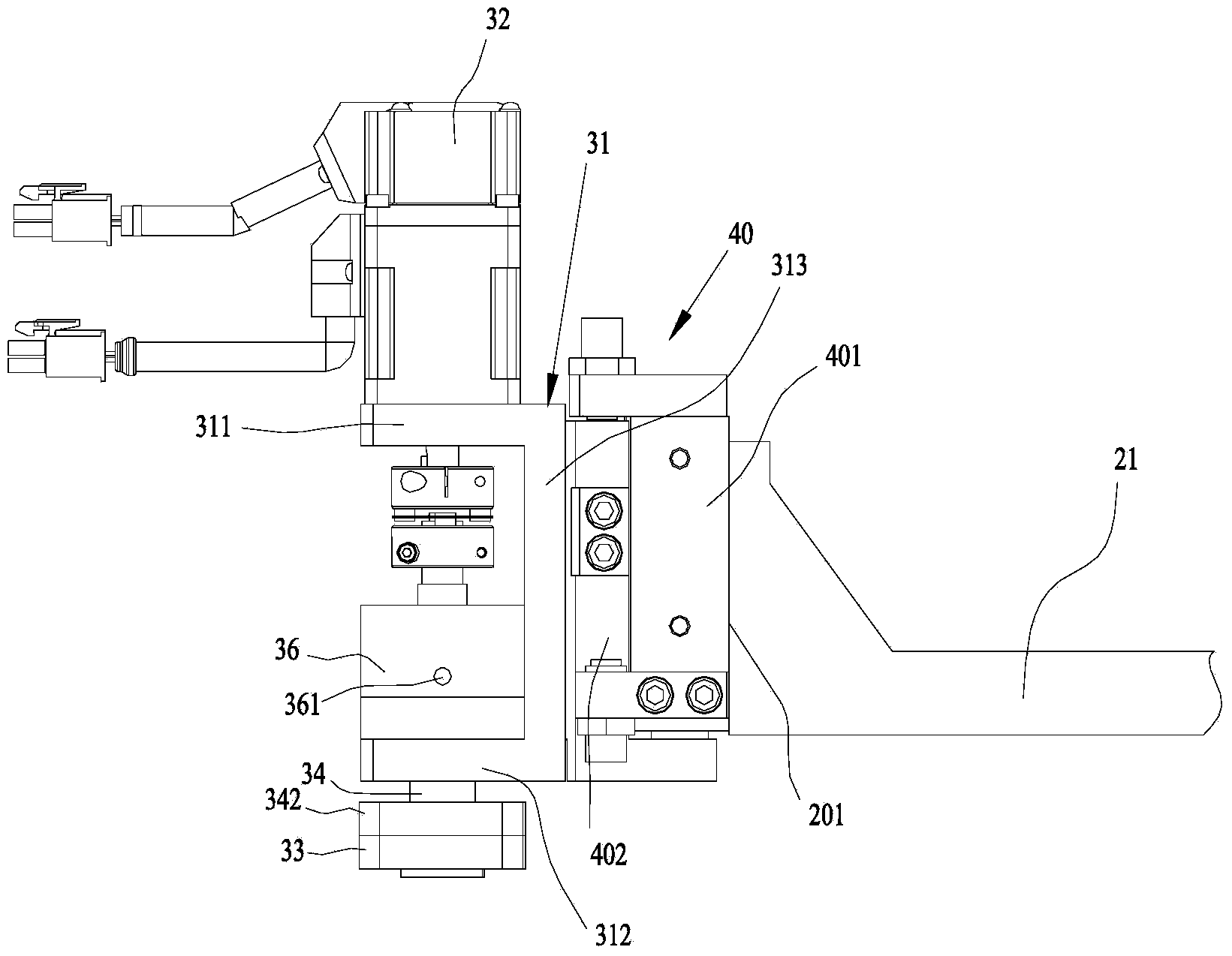

[0035] Such as Figure 1~2 , Figure 8 The shown reinforcing bonding device for flexible printed circuit boards includes a machine 18, a reinforcing sheet making mechanism 100 fixed on the surface of the machine 18 for making a reinforcing sheet 23, and a reinforcing sheet 23 for absorbing and moving The reinforcing sheet adsorption mechanism 200 and the positioning assembly 300 for positioning the flexible circuit board, the reinforcing sheet adsorption mechanism 200 includes a rotary drive device, a rotating frame 2 driven by the rotary drive device, and at least three for adsorbing the reinforcing sheet The adsorption assembly 3 of 23, the rotating frame 2 is installed on the output end of the rotating drive device, the rotating frame 2 has end portions 201 equal in number to the adsorption assembly 3, and each end portion 201 is symmetrically distributed with the rotation center line of the rotating frame 2; each A suction assembly 3 is vertically telescopically slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com